Organic and inorganic compound photo-initiation potential soil curing agent and preparation method thereof

A soil curing agent and inorganic composite technology, applied in the field of organic-inorganic composite light-initiated latent soil curing agent and its preparation, can solve the problems of easy cracking, water stability, low impact strength, poor weather resistance, etc., and achieve strong adhesion , low toxicity, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

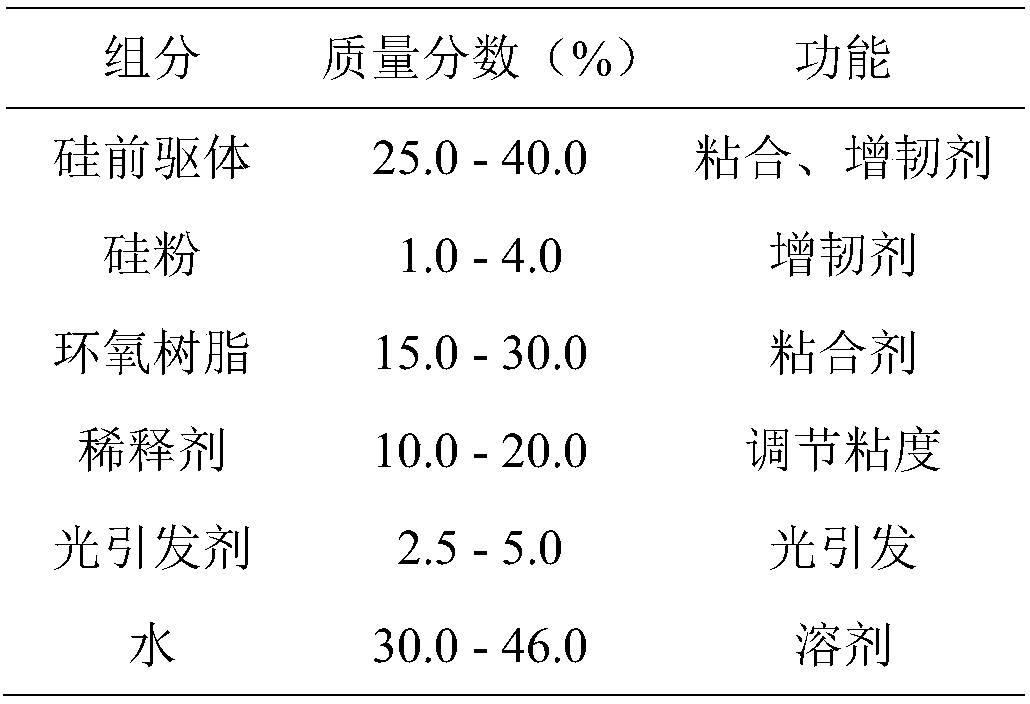

Method used

Image

Examples

Embodiment 1

[0024] Step a. Weigh 20g of epoxy resin, 3g of photoinitiator, 10g of epoxy diluent 501 and 1g of silicon powder and mix evenly with 37g of distilled water, and stir at room temperature for 6 hours.

[0025] Step b. A certain amount of 25g of sodium silicate was mixed in 5g of distilled water, and stirred for 10min. Step c. The solution prepared in step b is added dropwise to the solution prepared in step a under stirring, and then the mixed solution is stirred and reacted at room temperature for 6 hours.

[0026] Step d. The prepared soil is solidified with a dosage of 0.02%, evenly sprayed with silty soil, then mixed with 4% cement and mixed evenly, through a series of physical and chemical reaction processes, so as to achieve stable and durable soil solidification Effect. According to the test method of JTGE51 (T0805), the unconfined compressive strength of the reinforced soil was tested for 7d, 28d and 90d. In order to reflect the reinforcement effect of organic and inor...

Embodiment 2

[0029] Step a. Weigh 20g of epoxy resin, 3g of photoinitiator, 10g of epoxy diluent 501 and 2g of silicon powder and mix them evenly with 25g of distilled water, and stir at room temperature for 6 hours.

[0030] Step b. A certain amount of 30 g of sodium silicate silicon precursor was mixed with 5 g of distilled water, and stirred for 10 min.

[0031] Step c. Add the solution prepared in step b to the solution prepared in step dropwise under stirring, then stir and react at room temperature for 6 hours.

[0032]Step d. The prepared soil is solidified with an amount of 0.02%, evenly sprayed into the clay soil, and then mixed with 6% cement and mixed evenly. After a series of physical and chemical reaction processes, the stable and long-lasting effect of soil solidification is achieved. . According to the test method of JTG E51 (T0805), the unconfined compressive strength of the reinforced soil was tested for 7d, 28d and 90d. In order to reflect the reinforcement effect of or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com