Weather-resistant degradable plastic bottle and preparation method

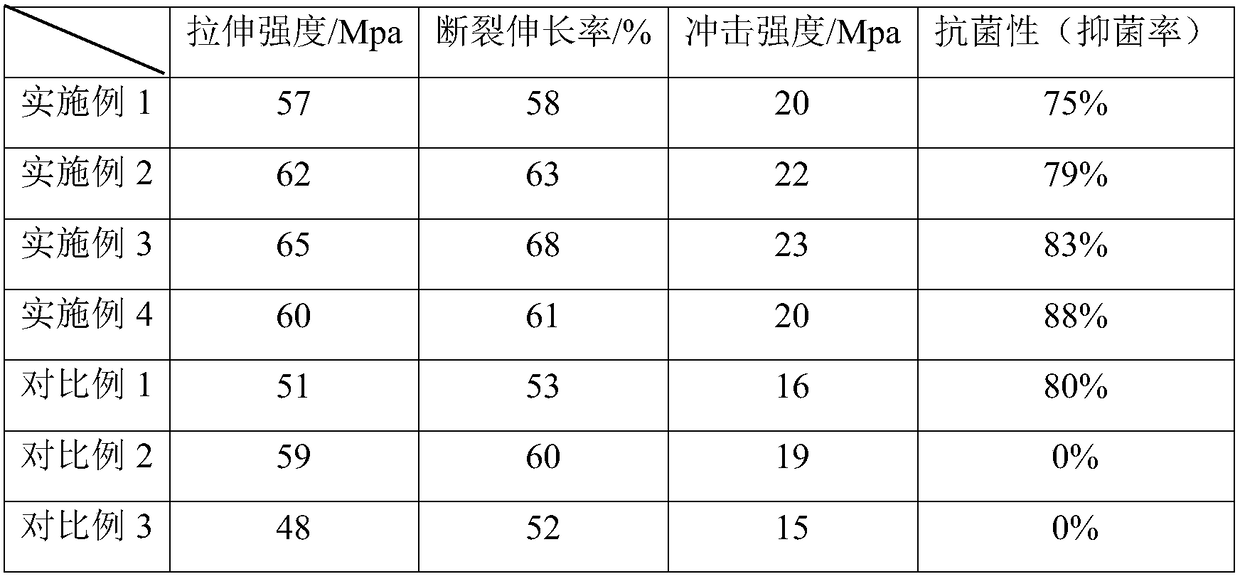

A degradable plastic and weather-resistant technology, which is applied in the field of plastic product production, can solve the problems of poor weather resistance, no UV resistance, poor dispersion of polylactic acid, etc., and achieve the effect of improving UV resistance, improving weather resistance and eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A weather-resistant degradable plastic bottle, the preparation method of which comprises the following steps:

[0034] (1) Dissolve 1 part of sodium pyrophosphate in 100 parts of deionized water, add 20 parts of attapulgite, stir at 30-60°C for 1 hour, take the upper suspension after standing for a while, add HCl solution, Stir at -60 °C for 1 h. centrifuged, washed with water until neutral and then dried to obtain purified attapulgite;

[0035] (2) Add γ-aminopropyltriethoxysilane solution to the purified attapulgite obtained in step (1), stir at 50°C for 2 hours, wash with alcohol and water three times, and then dry to obtain an amination modification After the attapulgite;

[0036] (3) Add a certain amount of xylene, methyl methacrylate, and initiator to the modified attapulgite obtained in step (2), ultrasonically disperse for 10-20min, and stir magnetically at 80°C for 3 minutes under a nitrogen atmosphere. -5h, washing and drying after completion of the reactio...

Embodiment 2

[0039] A weather-resistant degradable plastic bottle, the preparation method of which comprises the following steps:

[0040] (1) Dissolve 1 part of sodium pyrophosphate in 100 parts of deionized water, add 20 parts of attapulgite, stir at 30-60°C for 1 hour, take the upper suspension after standing for a while, add HCl solution, Stir at -60 °C for 1 h. centrifuged, washed with water until neutral and then dried to obtain purified attapulgite;

[0041] (2) Add aminosilane coupling agent solution to the purified attapulgite obtained in step (1), stir at 50°C for 2 hours, wash with alcohol and water three times, and then dry to obtain attapulgite after amination modification ;

[0042](3) Add a certain amount of xylene, methyl methacrylate, and initiator to the modified attapulgite obtained in step (2), ultrasonically disperse for 10-20min, and stir magnetically at 80°C for 3 minutes under a nitrogen atmosphere. -5h, washing and drying after completion of the reaction to obta...

Embodiment 3

[0045] A weather-resistant degradable plastic bottle, the preparation method of which comprises the following steps:

[0046] (1) Dissolve 1 part of sodium pyrophosphate in 100 parts of deionized water, add 20 parts of attapulgite, stir at 30-60°C for 1 hour, take the upper suspension after standing for a while, add HCl solution, Stir at -60 °C for 1 h. centrifuged, washed with water until neutral and then dried to obtain purified attapulgite;

[0047] (2) Add N-β(aminoethyl)-γ-aminopropyltrimethoxysilane solution to the purified attapulgite obtained in step (1), stir at 50°C for 2h, wash with alcohol and water three times respectively After drying, obtain the attapulgite after amination modification;

[0048] (3) Add a certain amount of xylene, methyl methacrylate, and initiator to the modified attapulgite obtained in step (2), ultrasonically disperse for 10-20min, and stir magnetically at 80°C for 3 minutes under a nitrogen atmosphere. -5h, washing and drying after comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com