Method for removing silver in silver-containing tin alloy by supergravity

A silver-tin alloy, super-gravity technology, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of difficult temperature control, difficult to remove, low safety, etc., and achieves the effects of safe and controllable process, reduced production cost, and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

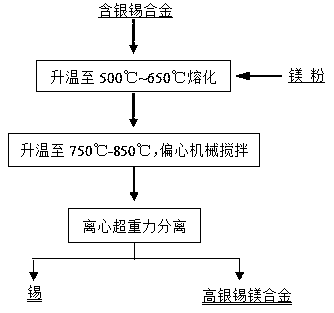

[0024] This method of removing silver from silver-containing tin alloys by supergravity firstly melts the silver-containing tin alloys fully, then adds magnesium powder into the melted silver-containing tin alloys, passes through argon gas for gas protection, and eccentric mechanically stirs, and waits for the magnesium After the powder is completely melted, the stirring is stopped, and the melt is subjected to centrifugal supergravity separation to obtain tin and high-silver tin-magnesium alloy with obvious stratification.

[0025] The specific steps are as follows:

[0026] Step 1. First, heat up 0.5kg of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 1.0g / t, and the rest is tin) to 500°C and fully melt it. : 4 Add magnesium, feed argon into the crucible for gas protection during the melting process (argon feed rate is 0.5Nm 3 / h); continue to heat up to 700 ° C, eccentric mechanical stirring for 5 minutes (the stirring speed of ecc...

Embodiment 2

[0030] This method of removing silver from silver-containing tin alloys by supergravity firstly melts the silver-containing tin alloys fully, then adds magnesium powder into the melted silver-containing tin alloys, passes through argon gas for gas protection, and eccentric mechanically stirs, and waits for the magnesium After the powder is completely melted, the stirring is stopped, and the melt is subjected to centrifugal supergravity separation to obtain tin and high-silver tin-magnesium alloy with obvious stratification.

[0031] The specific steps are as follows:

[0032] Step 1. First, heat 0.5kg of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 50,000g / t, and the rest is tin) to 650°C to fully melt, and according to the molar ratio of tin and magnesium in the silver-containing tin alloy: 1: 1. Magnesium is added, and argon gas is introduced into the crucible for gas protection during the melting process (the amount of argon gas i...

Embodiment 3

[0036] This method of removing silver from silver-containing tin alloys by supergravity firstly melts the silver-containing tin alloys fully, then adds magnesium powder into the melted silver-containing tin alloys, passes through argon gas for gas protection, and eccentric mechanically stirs, and waits for the magnesium After the powder is completely melted, the stirring is stopped, and the melt is subjected to centrifugal supergravity separation to obtain tin and high-silver tin-magnesium alloy with obvious stratification.

[0037] The specific steps are as follows:

[0038] Step 1. First, heat 0.5kg of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 10000g / t, and the rest is tin) to 600°C to fully melt, and according to the molar ratio of tin and magnesium in the silver-containing tin alloy: 1: 3 Add magnesium, and argon gas is passed into the crucible during the melting process for gas protection (the amount of argon gas introduced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com