Quality control method of cefixime

A quality control method and technology of cefixime, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of poor separation degree and/or peak shape of impurities, poor comprehensive detection effect, and poor detection effect of special unknown impurities And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

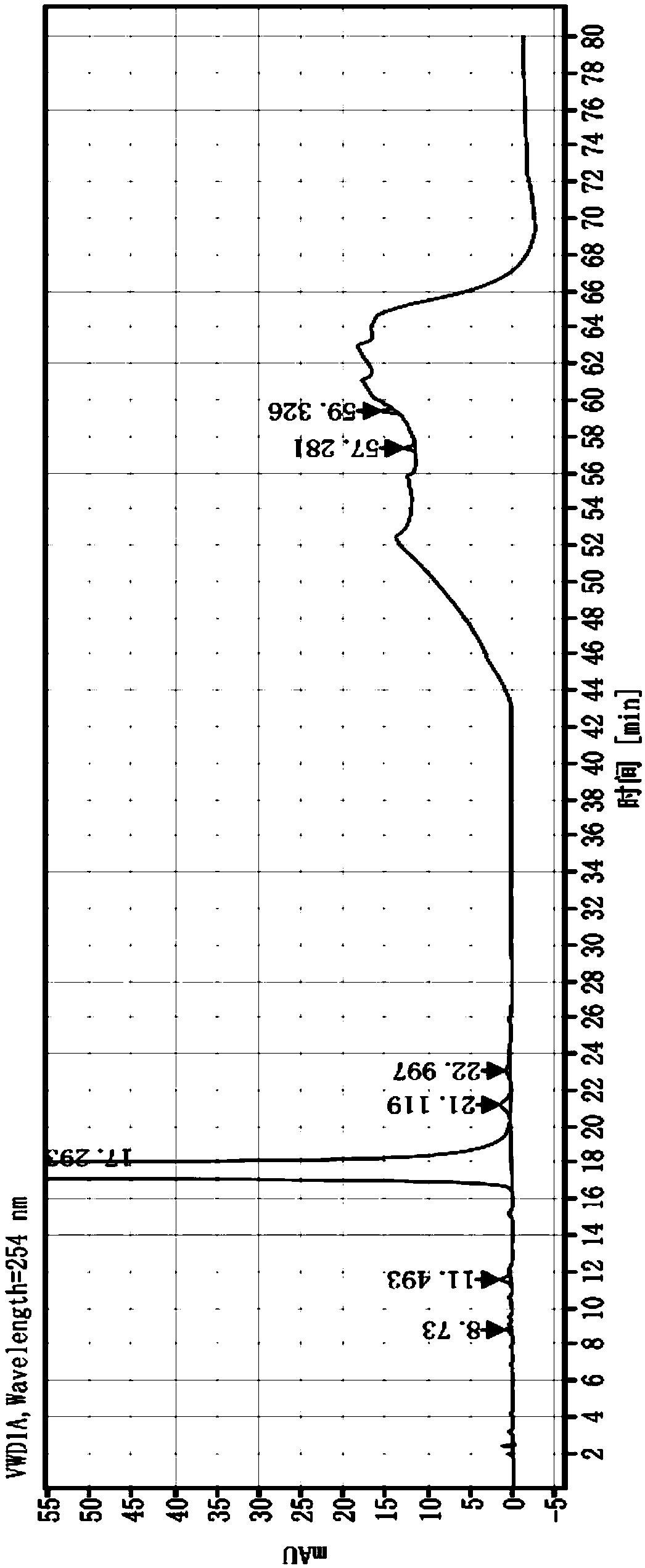

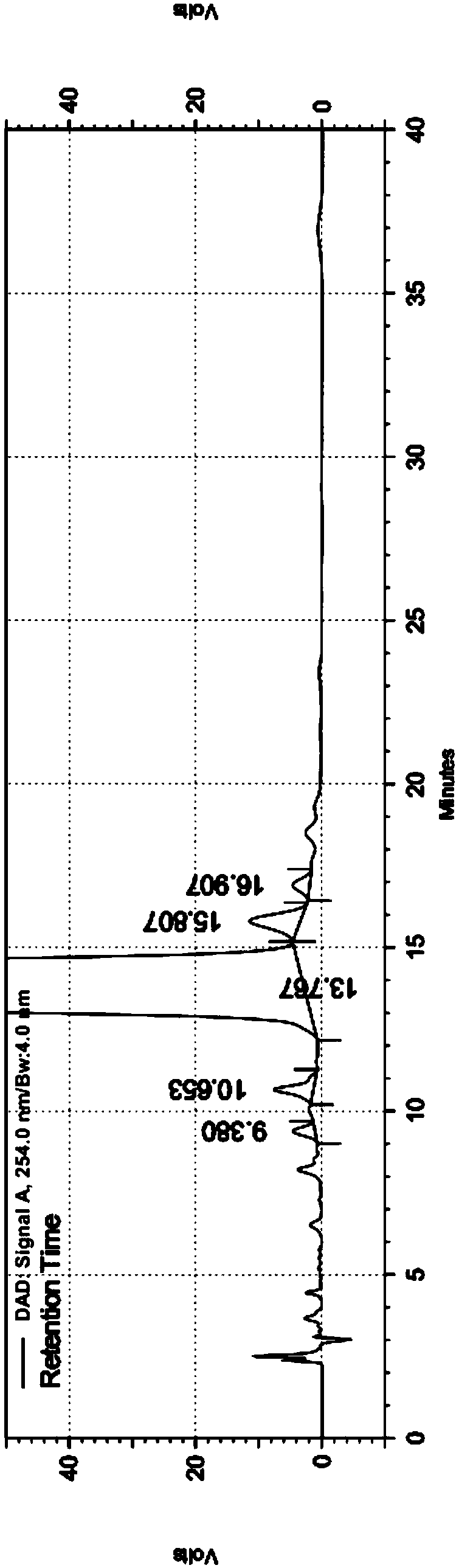

Embodiment 1

[0049] Chromatographic column: Agilent ZORBAX SB-C18, 250×4.6mm, 5μm

[0050] Mobile phase:

[0051] Phase A: Tetrabutylammonium hydroxide aqueous solution: Acetonitrile = 50:50

[0052] Phase B: Tetrabutylammonium hydroxide aqueous solution: Acetonitrile = 85:15

[0053] Column temperature: 40℃

[0054] Injection volume: 20μL

[0055] Injection concentration 1mg / mL

[0056] Flow rate: 1.2mL / min

[0057] Detection wavelength: 254nm

[0058] The quality control method of described cefixime comprises the following steps:

[0059] 1. Prepare the solution;

[0060] Take 25mL of 10% tetrabutylammonium hydroxide solution, add purified water to dilute to 1000mL, shake well, adjust pH to 6.5 with 1.5mol / L phosphoric acid solution to obtain tetrabutylammonium hydroxide aqueous solution; mix the corresponding amount of tetrabutylammonium hydroxide aqueous solution with acetonitrile , to obtain A phase and B phase, respectively;

[0061] Take 5 cefixime dispersible tablets (50mg s...

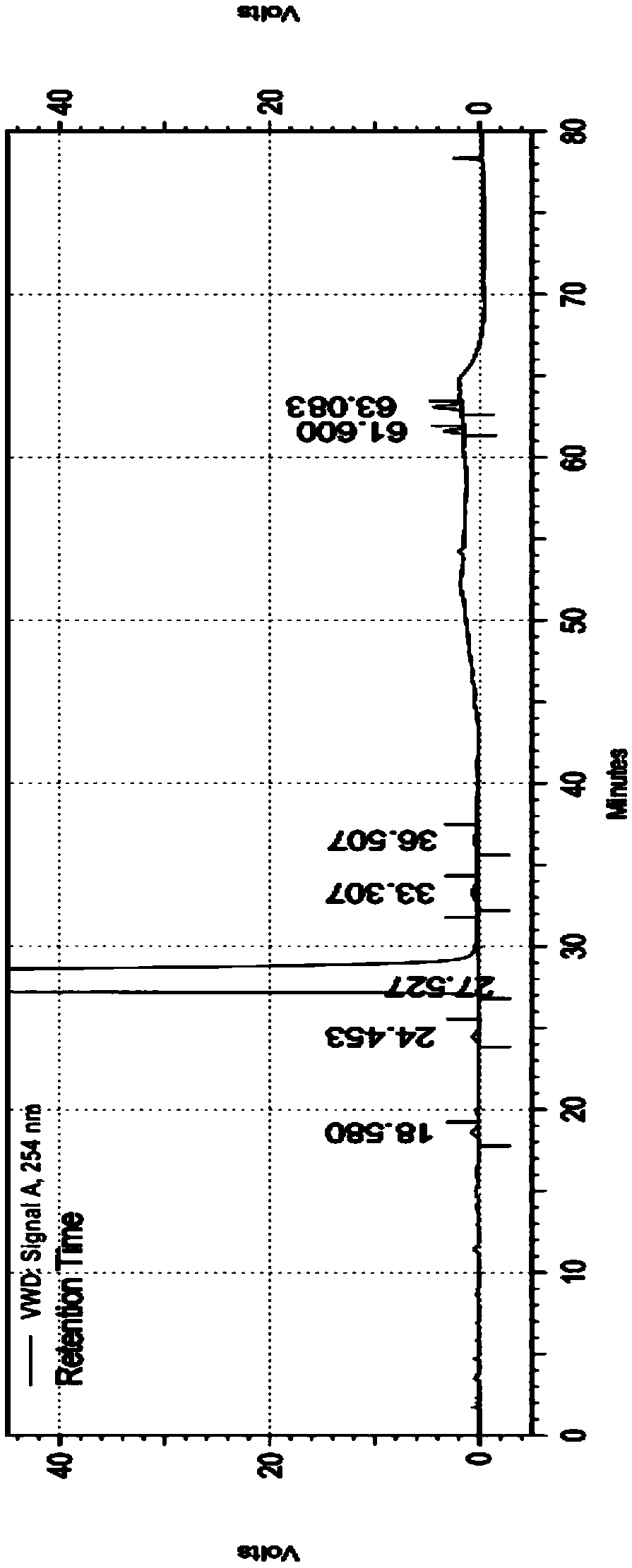

Embodiment 2

[0068] Chromatographic column: Agilent ZORBAX SB-C18, 250×4.6mm, 5μm

[0069] Mobile phase:

[0070] Phase A: Tetrabutylammonium hydroxide aqueous solution: Acetonitrile = 50:50

[0071] Phase B: Tetrabutylammonium hydroxide aqueous solution: Acetonitrile = 85:15

[0072] Column temperature: 40℃

[0073] Injection volume: 20μL

[0074] Injection concentration 1mg / mL

[0075] Flow rate: 1.2mL / min

[0076] Detection wavelength: 254nm

[0077] The quality control method of described cefixime comprises the following steps:

[0078] 1. Prepare the solution;

[0079] Take 25mL of 10% tetrabutylammonium hydroxide solution, add purified water to dilute to 1000mL, shake well, adjust pH to 6.5 with 1.5mol / L phosphoric acid solution to obtain tetrabutylammonium hydroxide aqueous solution; mix the corresponding amount of tetrabutylammonium hydroxide aqueous solution with acetonitrile , to obtain A phase and B phase, respectively;

[0080] Take 5 cefixime dispersible tablets (50mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com