Supported double-metal catalyst capable of efficiently synthesizing DBE (Dibasic Ester) and preparation method of supported double-metal catalyst

A bimetallic catalyst and a supported technology, which is applied to the supported bimetallic catalyst for the efficient synthesis of DBE and its preparation field, can solve the problems of side reactions, slowing down the reaction speed, hydrogenolysis and polymerization, etc., and improve the hydrogenation reaction rate. , improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

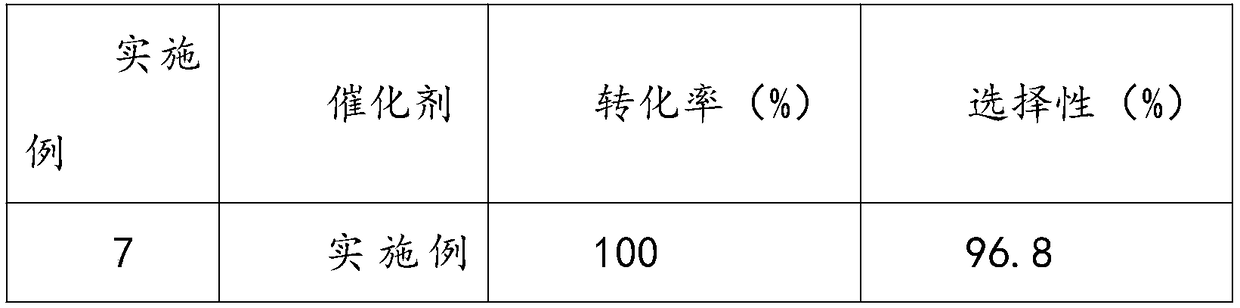

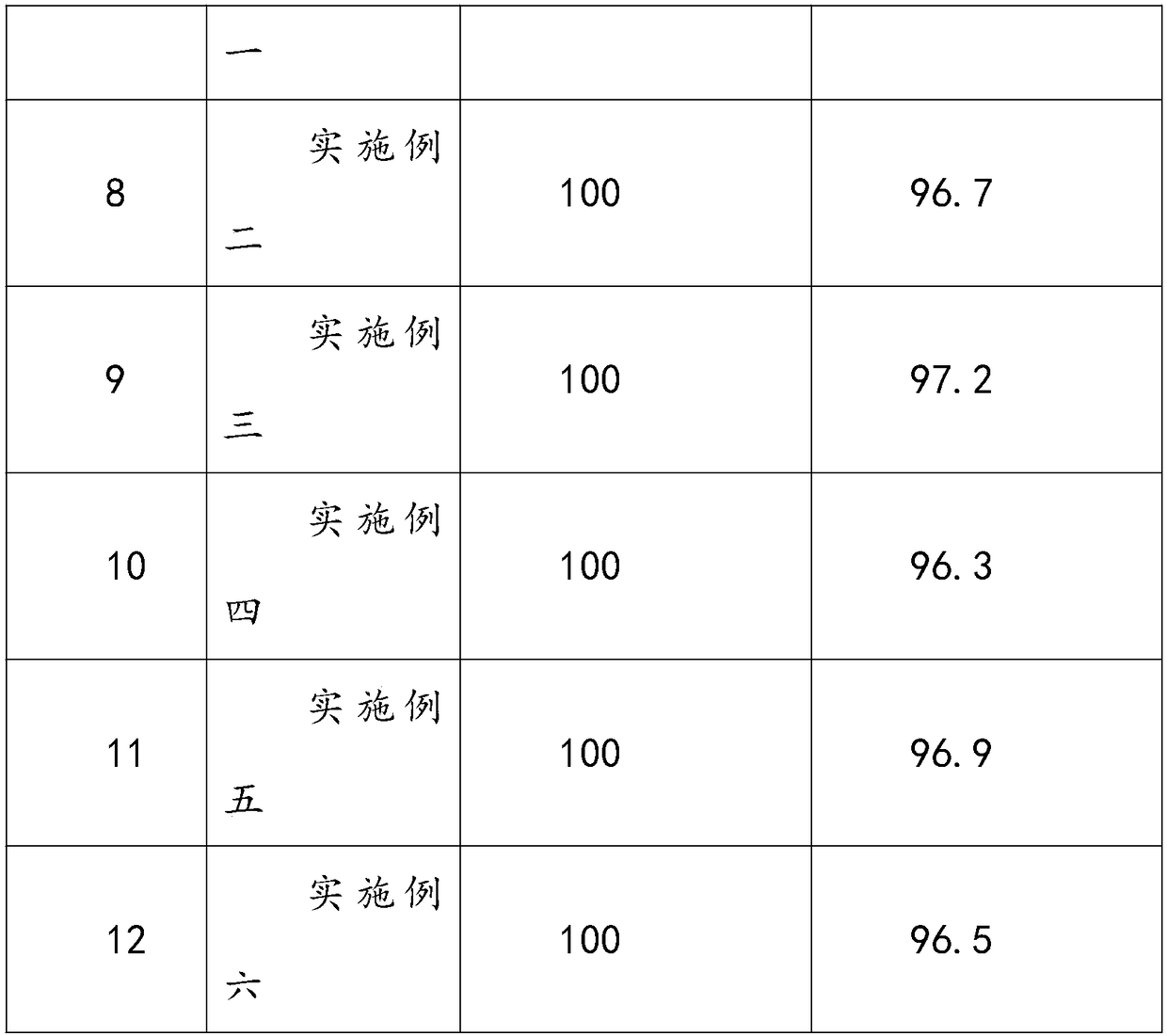

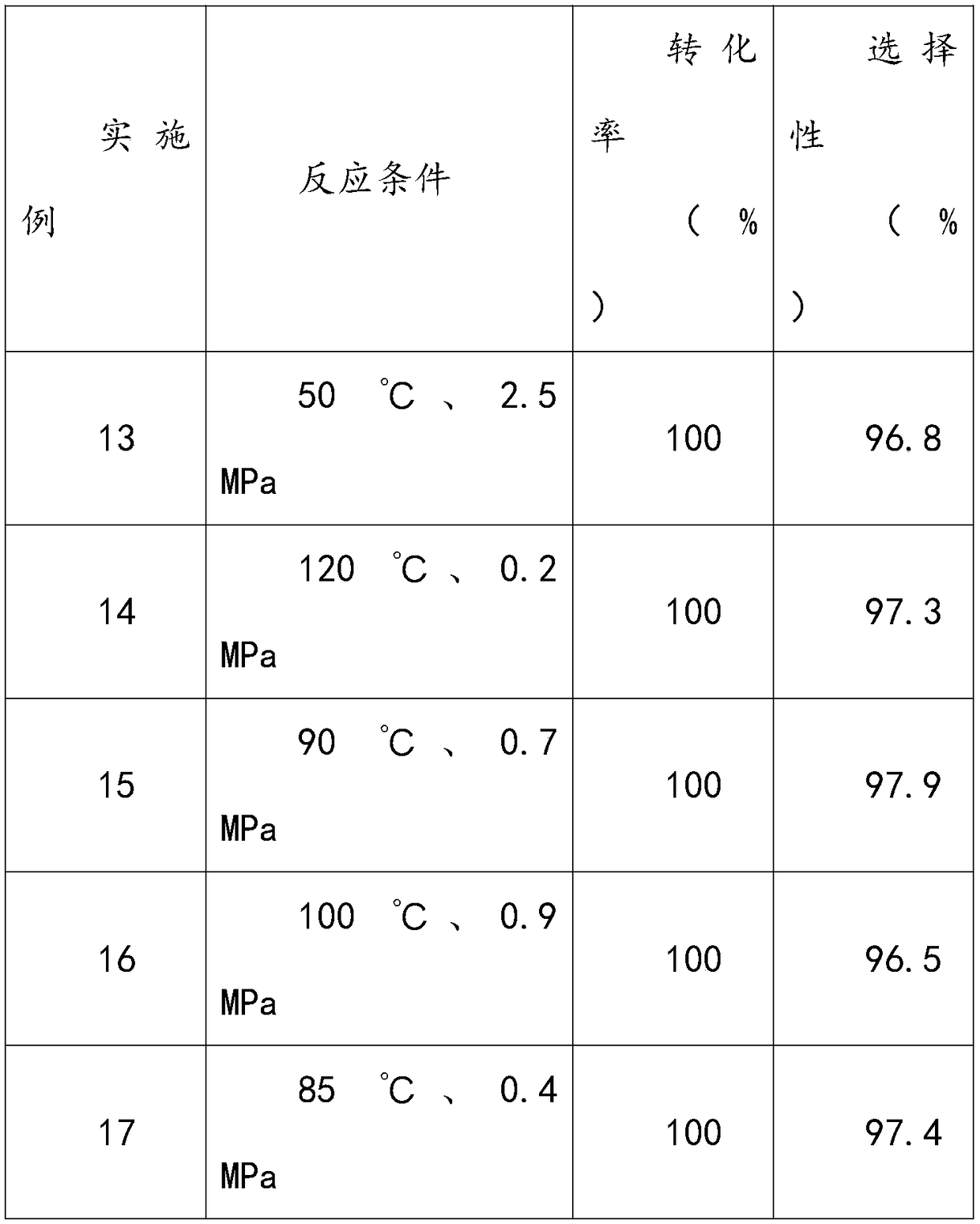

Examples

Embodiment 1

[0034] Weigh 10g of activated carbon, the particle size of activated carbon is 500 mesh, the specific surface area is 1300m2 / g, and the ash content is 1.0wt%, mix it with 0.5g urea, and treat it at 1000°C for 6h under nitrogen atmosphere to obtain nitrogen-doped Activated carbon. Then the above-mentioned nitrogen-doped activated carbon was prepared into a slurry with a temperature of 85° C. in 100 ml of deionized water, and 10 ml of H2PdCl4 solution (Pd content was 0.2 g / ml) and 10 ml of SnCl2 solution (Sn content was 0.1 g / ml) were slowly added dropwise. , stirred for 2h; the pH value of the solution was adjusted to 8 with 10wt% NaOH solution, and the temperature was lowered to room temperature, filtered, and the filter cake was washed with deionized water until neutral; then the filter cake was configured into a slurry at 85°C, and the Add 10ml of 85% hydrazine hydrate solution, stir for 2.5h, filter, wash the filter cake with deionized water until neutral, and dry it in vac...

Embodiment 2

[0036] Weigh 10g of activated carbon, the particle size of activated carbon is 800 mesh, the specific surface area is 1400m2 / g, and the ash content is 2wt%, it is placed in NH3, the gas flow rate is 1L / h, and it is treated at 900°C for 9h to obtain nitrogen-doped activated carbon. The above-mentioned nitrogen-doped activated carbon is formulated into a slurry with a temperature of 65° C. in 100 ml of deionized water, and slowly added dropwise with 6 ml of H2PtCl6 solution (Pt content is 0.1 g / ml) and 10 ml of SnCl4 solution (Sn content is 0.2 g / ml), Stir for 2.5h; use 10wt% KOH solution to adjust the pH value of the solution to 8.5, and lower the temperature to room temperature, filter, and wash the filter cake with deionized water until neutral; then configure the filter cake into a slurry at 65°C, drop Add 10ml of formaldehyde, stir for 2 hours, filter, wash the filter cake with deionized water until neutral, and dry it in vacuum at 100°C to obtain a nitrogen-doped activated ...

Embodiment 3

[0038] Weigh 10g of activated carbon, the particle size of activated carbon is 100 mesh, the specific surface area is 1100m2 / g, and the ash content is 3wt%, and it is mixed with 4g of melamine evenly, and treated at 1200°C for 3h under a helium atmosphere to obtain nitrogen-doped activated carbon. The above-mentioned nitrogen-doped activated carbon was prepared into a slurry at a temperature of 40°C in 100ml deionized water, and 10ml of Pd(NO3)2 solution (Pd content was 0.05g / ml) and 10ml of SnCl4 solution (Sn content was 0.3g / ml) were slowly added dropwise. / ml), stirred for 4 hours; adjusted the pH value of the solution to 9 with ammonia water, and lowered the temperature to room temperature, filtered, and washed the filter cake with deionized water until neutral; then configured the filter cake into a slurry at 40°C, and added dropwise 35ml of formic acid, stirred for 4 hours, filtered, the filter cake was washed with deionized water until neutral, and dried in vacuum at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com