Steel and iron industrial thick brine treatment device and method

A treatment device, a technology for the iron and steel industry, applied in the direction of multi-stage water treatment, water/sewage treatment, metallurgical wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

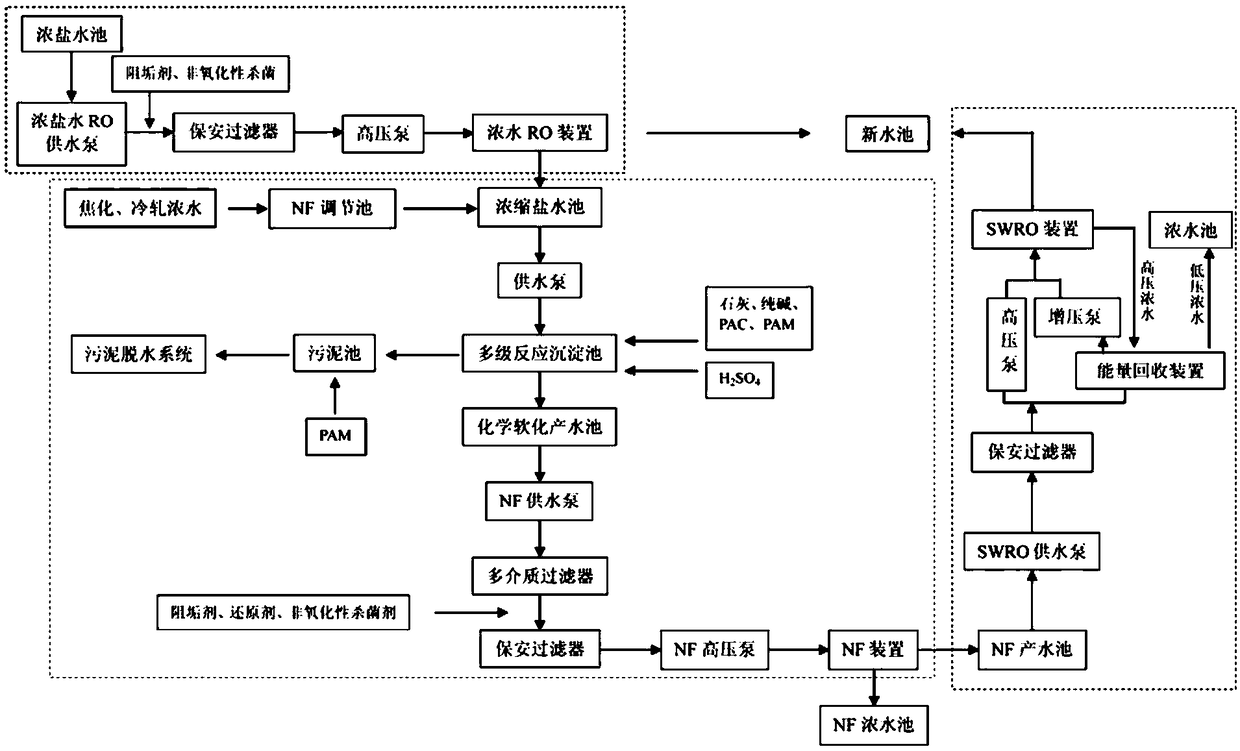

Method used

Image

Examples

Embodiment 1

[0110] Concentrated brine RO water supply pump 2 is RO water supply pump model DFWH200-315 from Dongfang Pump Industry, and concentrated brine security filter 3 is a security filter with large flow rate replaceable cassette filter element from Fischer, model PF-SWV40-4VDFE08W Concentrated brine RO high-pressure pump 4 uses Sulzer model A32-80SO high-pressure pump, concentrated water RO device 5 uses Dow’s model BW30FR-400 / 34i anti-pollution RO membrane, new water pool 6, concentrated brine pool 7 Concentrated brine RO treatment unit. Among them, the concentrated brine pool 1 is connected with the concentrated brine RO water supply pump 2 through pipelines, the concentrated brine RO water supply pump 2 is connected with the concentrated brine security filter 3, the concentrated brine security filter 3 is connected with the concentrated brine RO high pressure pump 4, and the concentrated brine RO The high-pressure pump 4 is connected to the concentrated water RO device 5 through...

Embodiment 2

[0114] Concentrated brine RO water supply pump 2 is high-pressure pump model DFWH150-315 from Dongfang Pump Industry Co., Ltd. Concentrated brine security filter 3 is a security filter with replaceable cassette filter element from Fischer. Concentrated brine RO high-pressure pump 4 is Sulzer The model is the high-pressure pump of SNS4-65, concentrated water RO device 5 adopts BW30FR-400 anti-pollution RO membrane sold by Dow, the concentrated brine RO treatment unit composed of new water pool 6 and concentrated brine pool 7. The NF regulating tank 8, the water supply pump 9 and the NF water supply pump 13 are horizontal centrifugal pumps of the Dongfang Pump Industry Model DFW200-250 / 4 / 30, 10 multi-stage reaction sedimentation tanks, 11 chemical softening water production tanks, 12 sludge tanks, The multi-media filter 14 is a DN3000 steel-lined rubber multi-media filter sold by Jiangsu Wenbo Environmental Protection Equipment Co., Ltd., and the NF security filter 15 is a securi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com