Method for deeply removing cadmium in high-concentration cobalt sulfate solution and recovering cadmium

A cobalt sulfate solution and high-concentration technology, which is applied in the preparation of cobalt sulfate and cobalt compounds, and the improvement of process efficiency, etc., can solve the problems of increasing the workload of recycling and processing, unable to realize industrial application, and reducing the extraction rate of cobalt or nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

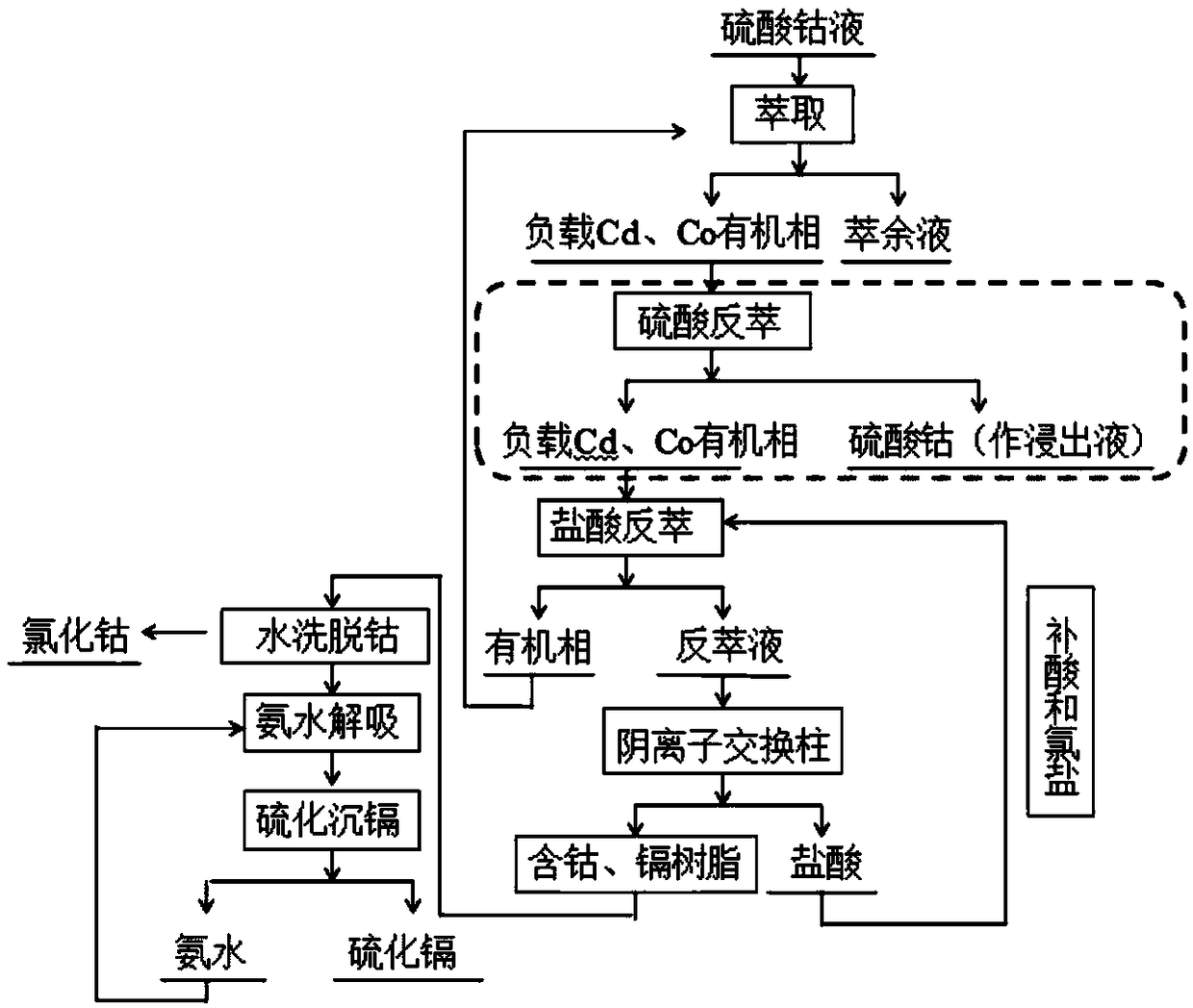

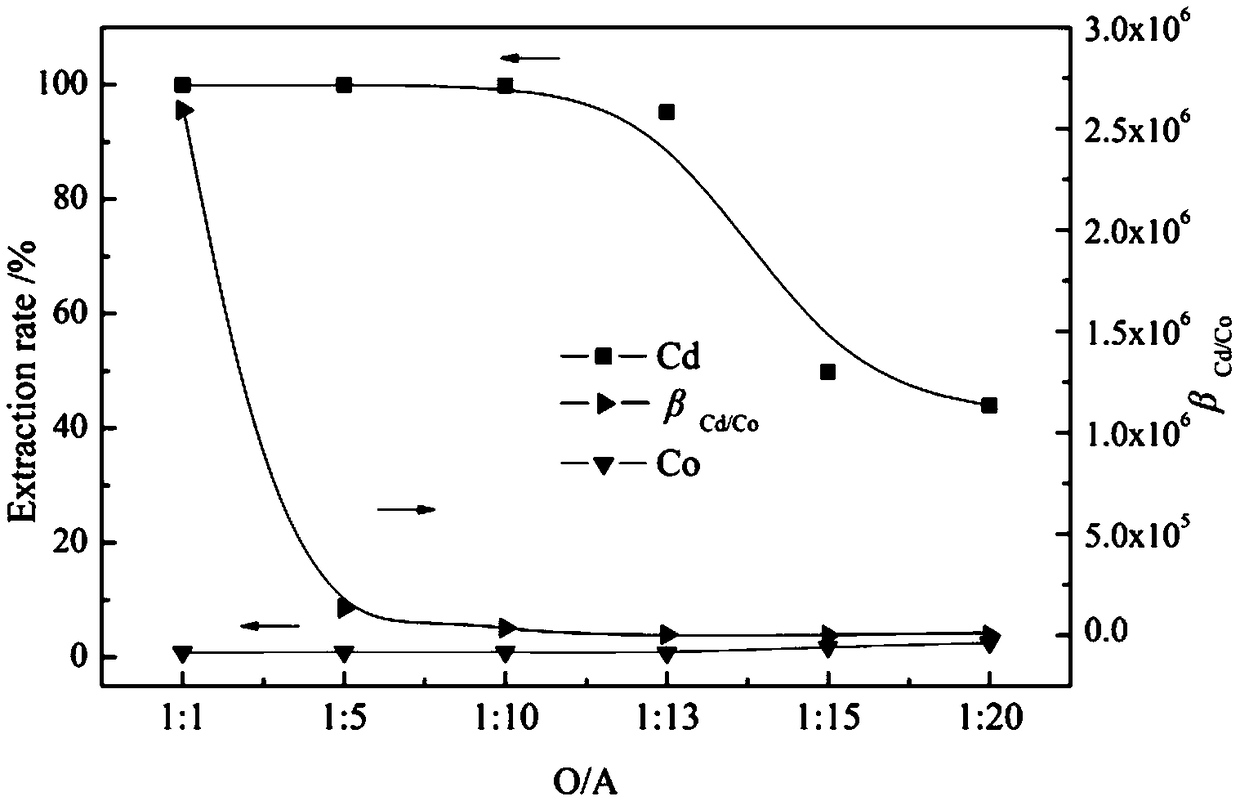

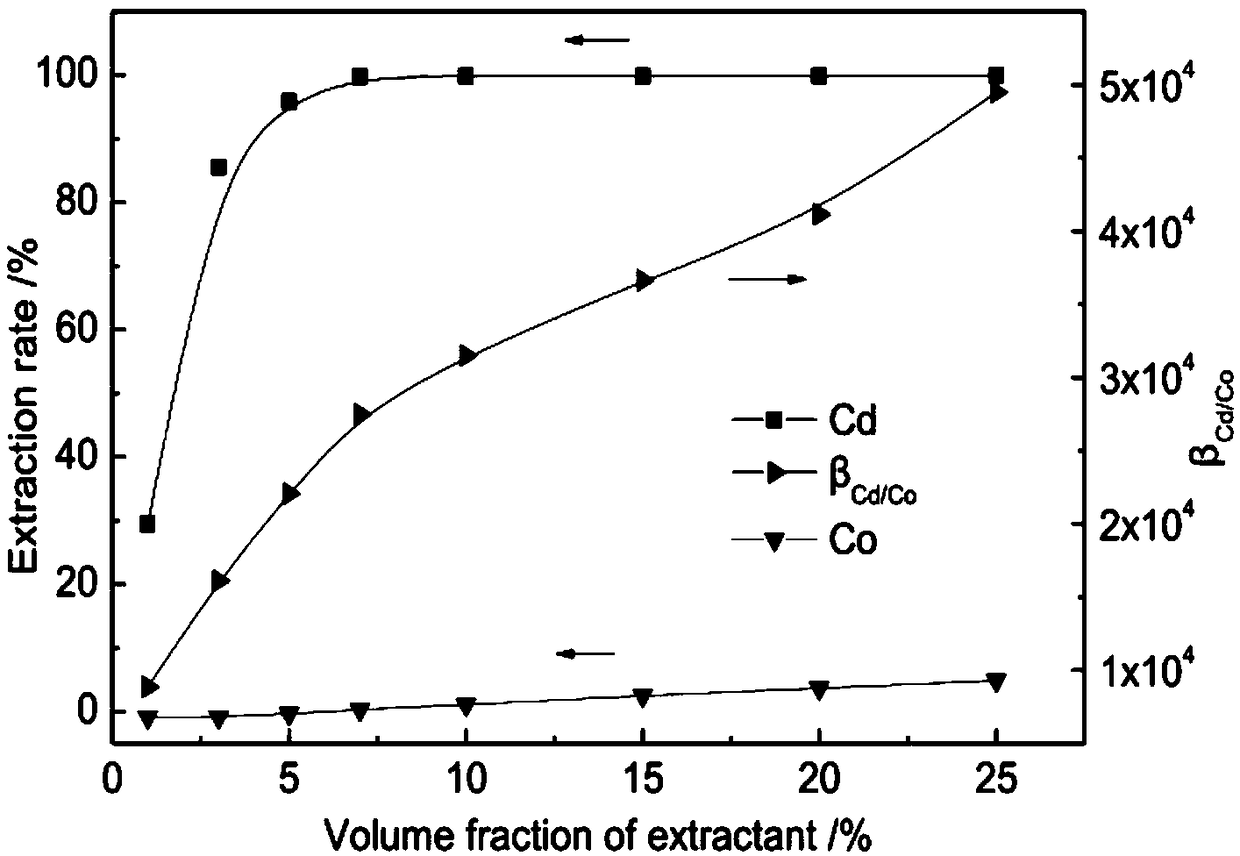

[0115] Configure cobalt sulfate solution (Co: 90g / L; Cd: 2.813g / L), organic phase 10% Cyanex301, measure 20ml of cobalt sulfate solution (pH=1.82) and 20ml of organic phase, pour into a separatory funnel, extraction time For 10min, compared with O:A=1:1, the raffinate is released, and then add stripping agent 20ml (3mol / L, H 2 SO 4 ), then the separatory bottle was placed on a constant temperature shaker (T=25° C.), and the stripping time was 10 min. Compared with O:A=1:1, the stripping solution was discharged (the concentration of cobalt in the detection solution), and then Add 20ml of stripping agent (7mol / L, HCl), and then place the separatory bottle on a constant temperature shaker (T=25°C). The stripping time is 10min. Compared with O:A=1:1, the stripping liquid Released, the organic phase can be used for the extraction of the next batch of solutions. The stripping solution passes through the anion exchange column to obtain a resin containing cobalt and cadmium, and the ...

Embodiment 2

[0118] Configure cobalt sulfate solution (Co: 90g / L; Cd: 0.24g / L), organic phase 10% Cyanex301, measure 20ml of cobalt sulfate solution (pH=1.82) and 20ml of organic phase, pour into a separatory funnel, extraction time For 10min, compared with O:A=1:5, the raffinate is released, and then add stripping agent 20ml (3mol / L, H 2 SO 4 ), then the separatory bottle was placed on a constant temperature shaker (T=25° C.), and the stripping time was 10 min. Compared with O:A=1:1, the stripping solution was discharged (the concentration of cobalt in the detection solution), and then Add 20ml of stripping agent (7mol / L, HCl), and then place the separatory bottle on a constant temperature shaker (T=25°C). The stripping time is 10min. Compared with O:A=1:1, the stripping liquid Released, the organic phase can be used for the extraction of the next batch of solutions. The stripping solution passes through the anion exchange column to obtain a resin containing cobalt and cadmium, and the e...

Embodiment 3

[0121] Configure cobalt sulfate solution (Co: 90g / L; Cd: 2.813g / L), organic phase 10% Cyanex301, measure 20ml of cobalt sulfate solution (pH=1.82) and 20ml of organic phase, pour into a separatory funnel, extraction time For 10min, compared with O:A=1:1, the raffinate is released, and then add stripping agent 20ml (3mol / L, H 2 SO 4 ), then the separatory bottle was placed on a constant temperature shaker (T=25° C.), and the stripping time was 10 min. Compared with O:A=1:1, the stripping solution was discharged (the concentration of cobalt in the detection solution), and then Add 20ml of stripping agent (7mol / L, HCl), and then place the separatory bottle on a constant temperature shaker (T=25°C). The stripping time is 10min. Compared with O:A=1:2, the stripping liquid Released, the organic phase can be used for the extraction of the next batch of solutions. The stripping liquid passes through the anion exchange column to obtain a resin containing cobalt and cadmium, and the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com