Alloy capable of improving creep resistance

An anti-creep and alloy technology, applied in the direction of electrode carrier/collector, electrical components, battery electrodes, etc., can solve the problems of unreasonable current distribution, short cycle life, poor corrosion resistance, etc., to improve deep cycle performance, Effect of reducing passivation, improving corrosion resistance and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

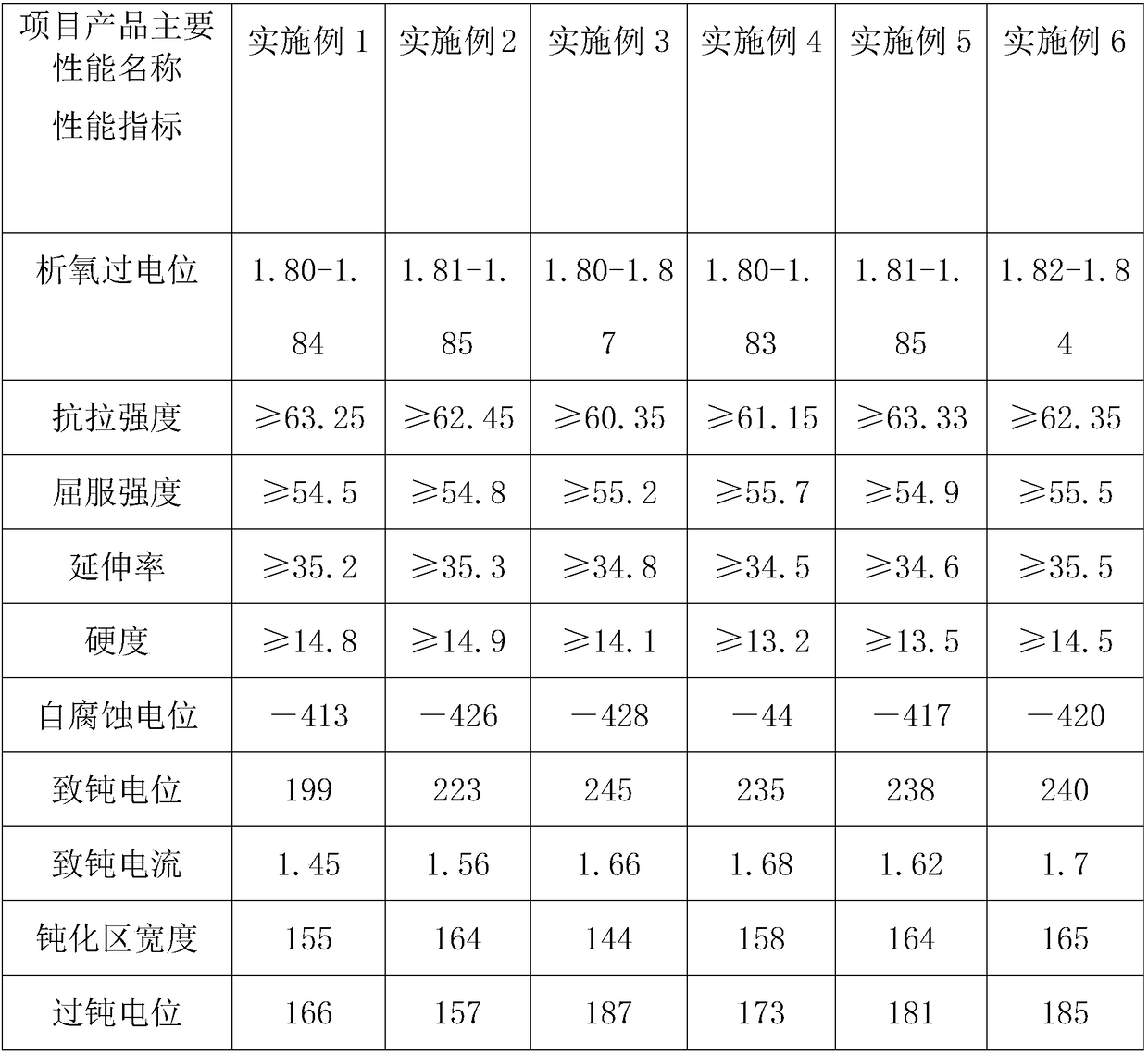

Examples

Embodiment 1

[0026] An alloy with improved creep resistance, the raw materials and percentages used in the alloy with improved creep resistance are: 2wt% silicon, 0.01wt% sulfur, 25wt% chromium, 25wt% iron, 6wt% cobalt, 22wt% nickel, 2.2wt% copper, 4.3wt% molybdenum, 5.1wt% boron, 0.1wt% carbon and 0.01wt% rare earth, 1.3wt% magnesium, 2.8wt% Manganese and 0.01 wt% Selenium.

[0027] The rare earth elements are neodymium and lanthanum, and the ratio of neodymium and lanthanum in the rare earth elements is 1:2.

[0028] The alloy adopts sand casting and investment casting processes, the alloy has a yield strength of at least 55.5MPa at room temperature, the alloy has a tensile strength of at least 62.35MPa at room temperature, and the hardness of the alloy at room temperature is The hardness is 40HCR.

[0029] The alloy can be prepared according to a conventional method using common production equipment, and the specific steps can include:

[0030] a) Calculate and weigh the amount of ea...

Embodiment 2

[0036] An alloy with improved creep resistance, the raw materials and percentages used in the alloy with improved creep resistance are: 2.5wt% silicon, 0.03wt% sulfur, 33wt% chromium, 33wt% iron , 8wt% cobalt, 29wt% nickel, 5.3wt% copper, 5.2wt% molybdenum, 6.3wt% boron, 0.25wt% carbon and 0.2wt% rare earth, 2.6wt% magnesium, 4.1wt% of manganese and 0.05wt% of selenium.

[0037] The rare earth elements are neodymium and lanthanum, and the ratio of neodymium and lanthanum in the rare earth elements is 1:2.

[0038] The alloy adopts sand casting and investment casting processes, the alloy has a yield strength of at least 55.5MPa at room temperature, the alloy has a tensile strength of at least 62.35MPa at room temperature, and the hardness of the alloy at room temperature is The hardness is 60HCR.

[0039] The alloy can be prepared according to a conventional method using common production equipment, and the specific steps can include:

[0040] a) Calculate and weigh the amou...

Embodiment 3

[0047] An alloy with improved creep resistance, the raw materials and percentages used in the alloy with improved creep resistance are: 2wt% silicon, 0.01wt% sulfur, 25wt% chromium, 25wt% iron, 6wt% cobalt, 22wt% nickel, 2.2wt% copper, 4.3wt% molybdenum, 5.1wt% boron, 0.1wt% carbon and 0.01wt% rare earth, 1.3wt% magnesium, 2.8wt% Manganese and 0.01 wt% Selenium.

[0048] The rare earth element is neodymium and lanthanum, and the ratio of neodymium and lanthanum in the rare earth element is 1:2. When mixing rare earth raw materials, 1.1wt% tin and 0.07-0.9wt% calcium are added.

[0049] The alloy adopts sand casting and investment casting processes, the alloy has a yield strength of at least 55.5MPa at room temperature, the alloy has a tensile strength of at least 62.35MPa at room temperature, and the hardness of the alloy at room temperature is The hardness is 40HCR.

[0050] The alloy can be prepared according to a conventional method using common production equipment, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com