Three-dimensional ordered macroporous titanate and in-situ self-sacrificial preparation method thereof

A three-dimensional ordered, porous titanate technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of large product shrinkage, incomplete pore structure, low filling rate, etc. The effect of simple process, low equipment requirements and high filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

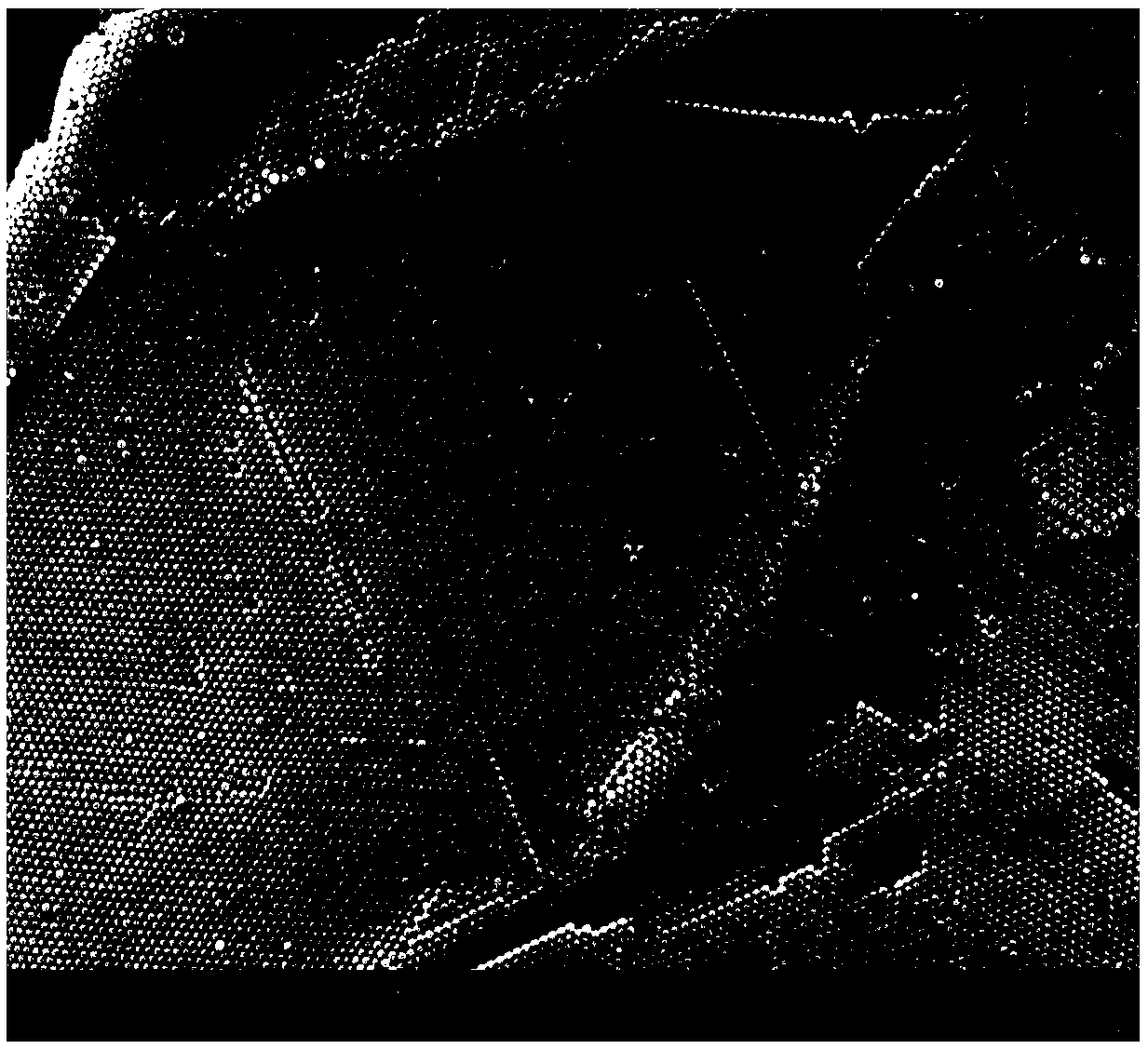

[0050] (1) Prepare monodisperse PS microspheres by dispersion polymerization, self-assemble PS microspheres into PS colloidal crystal templates by centrifugation, and dry them at 70°C;

[0051] (2) Isopropyl titanate is directly used as solution A;

[0052] (3) Soak the PS colloidal crystal template in methanol solution first, place it in a vacuum drying oven, and keep it at a vacuum degree of 20.133kPa for 20min; then take it out and filter out the methanol solution, and immediately fill it with methanol solution The PS colloidal crystal template is placed in solution A, and it is also placed in a vacuum oven and kept at a vacuum degree of 20.133kPa for 30min. Finally, it is taken out and the isopropyl titanate is filtered off, and the isopropyl titanate is filled with The ester PS colloidal crystal template was placed at room temperature for 12 hours to hydrolyze and gel the precursor solution isopropyl titanate in the structure;

[0053] (4) Calcining the PS colloidal crys...

Embodiment 2

[0058] (1) Prepare monodisperse PS microspheres by dispersion polymerization, self-assemble PS microspheres into PS colloidal crystal templates by centrifugation, and dry them at 70°C;

[0059] (2) directly use isopropyl titanate as solution A;

[0060] (3) Soak the PS colloidal crystal template in methanol solution first, place it in a vacuum drying oven, and keep it at a vacuum degree of 20.133kPa for 20min; then take it out and filter out the methanol solution, and immediately fill it with methanol solution The PS colloidal crystal template is placed in isopropyl titanate solution, and it is also placed in a vacuum drying oven and kept at a vacuum degree of 20.133kPa for 20min. Finally, it is taken out and the isopropyl titanate is filtered off, and the filled with The colloidal crystal template of isopropyl titanate was placed at room temperature for 12 hours to hydrolyze and gel the precursor solution in the structure;

[0061] (4) Calcining the PS colloidal crystal temp...

Embodiment 3

[0067] (1) Prepare monodisperse PS microspheres by dispersion polymerization, self-assemble PS microspheres into PS colloidal crystal templates by centrifugation, and dry them at 70°C;

[0068] (2) Mix tetraisopropyl titanate and absolute ethanol at a volume ratio of 1:1, and magnetically stir for 30 minutes to obtain a uniform solution A;

[0069] (3) Soak the PS colloidal crystal template in methanol solution first, place it in a vacuum drying oven, and keep it at a vacuum degree of 30.133kPa for 30min; then take it out and filter out the methanol solution, and then immediately fill it with methanol solution The PS colloidal crystal template is placed in solution A, and it is also placed in a vacuum oven and kept at a vacuum degree of 30.133kPa for 30min. Finally, it is taken out and solution A is filtered out, and the PS colloidal crystal template filled with solution A Place at room temperature for 24 hours to hydrolyze and gel the precursor solution in the structure;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com