Graphene-based inflaming retarding leather fat mixture and preparation method thereof

A leather fatliquor, graphene-based technology, applied in the field of leather chemicals, can solve the problems of reducing graphene performance, graphene agglomeration and precipitation, etc., to achieve the effects of improving flame retardant performance, solving agglomeration and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

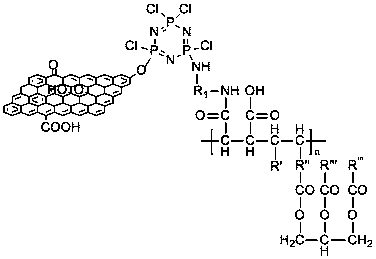

Image

Examples

Embodiment 1

[0029] (1) Preparation of aminated graphene, in parts by weight

[0030] 10 parts of graphene oxide and a certain amount of organic solvent were added to a 500 mL round-bottomed flask equipped with a nitrogen protection device, mechanical stirring and a constant pressure dropping funnel, and ultrasonically dispersed for 1.0 h; 25 parts of triethylamine were added, and 35 parts of hexachlorocyclotriphosphorus cyanide diluted with organic solvent was added dropwise to the reaction solution, and the reaction was carried out at 60 °C for 6 h; then 30 parts of ethylenediamine were added dropwise to the system, and the reaction was carried out at 60 °C for 10 h; finally, it was cooled and filtered under reduced pressure. , washed with absolute ethanol, and vacuum-dried to obtain aminated graphene;

[0031] (2) Preparation of grease-maleic anhydride copolymer, in parts by weight

[0032] 100 parts of rapeseed oil and 35 parts of maleic anhydride monomer were added to the three-necke...

Embodiment 2

[0037] (1) Preparation of aminated graphene, in parts by weight

[0038] 10 parts of graphene oxide and a certain amount of organic solvent were added to a 500 mL round-bottomed flask equipped with a nitrogen protection device, mechanical stirring and a constant pressure dropping funnel, and ultrasonically dispersed for 1.0 h; 25 parts of triethylamine were added, and 35 parts of hexachlorocyclotriphosphorus cyanide diluted with organic solvent was added dropwise to the reaction solution, and the reaction was carried out at 60 °C for 6 h; then 35 parts of p-phenylenediamine were added dropwise to the system, and the reaction was carried out at 60 °C for 10 h; Filtration, washing with absolute ethanol, and vacuum drying to obtain aminated graphene;

[0039] (2) Preparation of grease-maleic anhydride copolymer, in parts by weight

[0040] Add 100 parts of rapeseed oil and 35 parts of maleic anhydride monomer into a three-necked flask, heat up to 60 ℃ under stirring conditions t...

Embodiment 3

[0045] (1) Preparation of aminated graphene, in parts by weight

[0046] 10 parts of graphene oxide and a certain amount of organic solvent were added to a 500 mL round-bottomed flask equipped with a nitrogen protection device, mechanical stirring and a constant pressure dropping funnel, and ultrasonically dispersed for 1.0 h; 16 parts of pyridine were added, and organic 35 parts of hexachlorocyclotriphosphorus cyanide diluted with solvent was added dropwise to the reaction solution, and the reaction was carried out at 60 °C for 6 h; then 30 parts of ethylenediamine were added dropwise to the system, and the reaction was carried out at 60 °C for 10 h; Washing with water ethanol and vacuum drying to obtain aminated graphene;

[0047] (2) Preparation of grease-maleic anhydride copolymer, in parts by weight

[0048] Add 100 parts of soybean oil and 35 parts of maleic anhydride monomers into the three-necked flask, heat up to 60 °C under stirring to make maleic anhydride and soyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com