Method for inhibiting lifting of metal particle through composite film deposited on discharge plasma

A discharge plasma and composite thin film technology, which is applied in the field of plasma deposition, can solve problems such as lack of methods, ineffective suppression of metal particles, and residual air gap between electrodes and films, so as to suppress the lifting of metal particles and facilitate the slow transition of electric field , to avoid the effect of electric field gradient mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

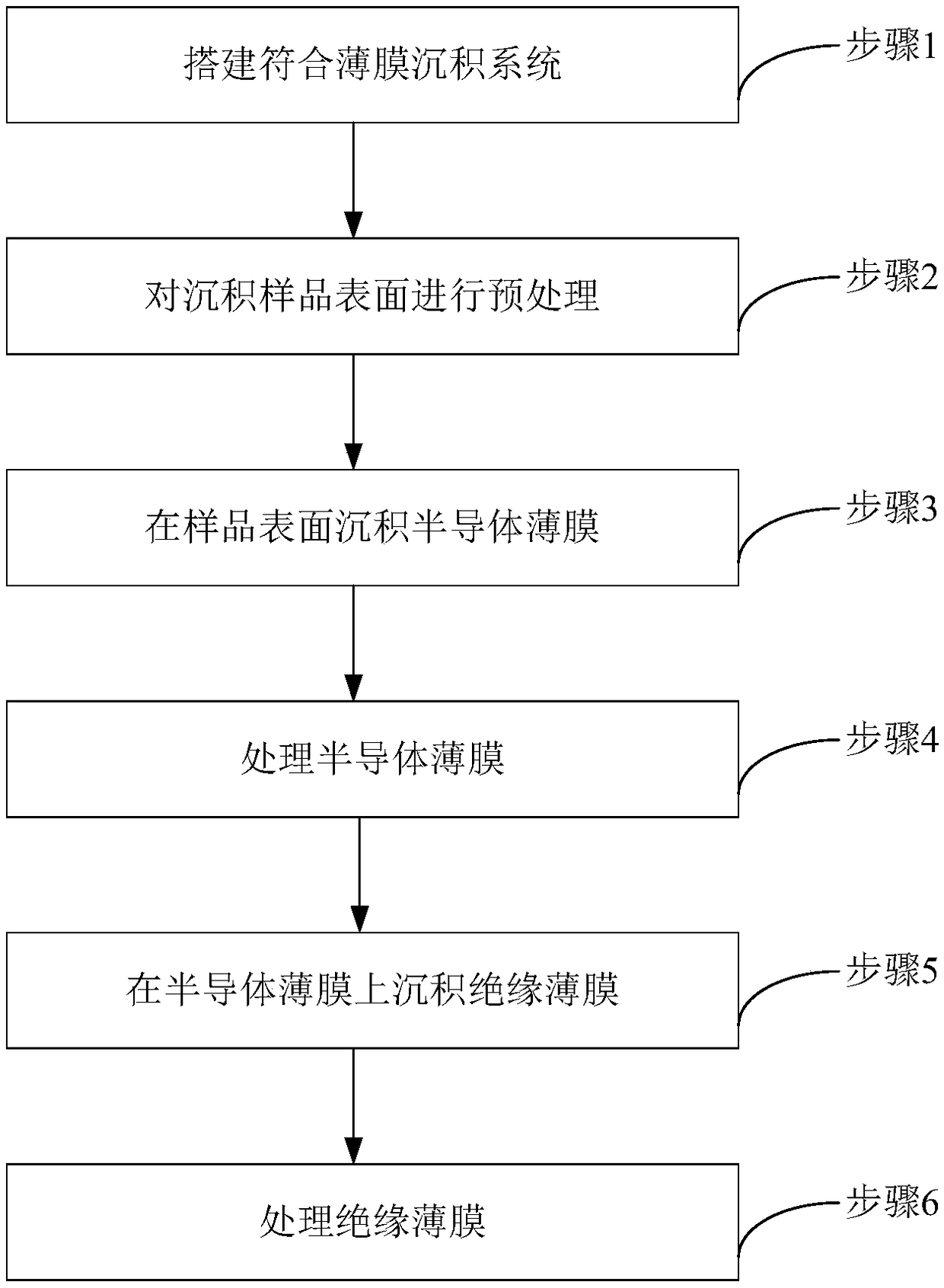

Method used

Image

Examples

Embodiment 1

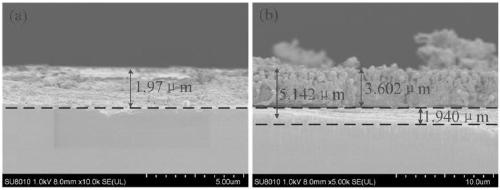

[0074] Deposition of TiO on copper surface by jet plasma 2 -SiO 2 Composite thin film, the excitation source adopts self-made high-frequency AC power supply HFHV30-2, the voltage amplitude during stable discharge is set to 11kV, the repetition frequency is 20kHz, Ar is used as the excitation gas, the flow rate is set to 4L / min, and another Ar is used as the Carrier gas, which takes the precursor (TiCl 4 The flow rate of TEOS is 50mL / min, and the flow rate of TEOS is 300mL / min), which is mixed with the excitation gas and passed into the discharge electrode. At the same time, it is also mixed with 50mL / min of O 2 To increase the density of the deposited film. First deposit TiO on the Cu surface 2 Thin film for 3min, then on TiO 2 Deposited SiO on the surface 2 Film 5min. The treated samples were tested by SEM and FTIR, respectively. Such as image 3 Shown is TiO deposited on Cu surface 2 Thin films and TiO 2 -SiO 2 SEM cross-section of the bilayer composite film with ...

Embodiment 2

[0076] The model was established by COMSOL to calculate the electric field distortion between the metal particles and the high-voltage electrode before and after the metal electrode surface was covered with a composite film. Spherical copper particles are used, the diameter is 0.2mm, the distance between the upper and lower plates is 4mm, the thickness of the film is 5μm, the voltage of the upper plate is 50kV, the polarity is negative, and the lower plate is grounded. Through the finite element analysis and calculation of the model, it can be concluded that the field strength between the metal particles and the high-voltage electrode near the metal particles reaches the maximum value, and the maximum field strength when the electrode surface is not coated is 1.98×10 8 V / m, while SiO is deposited on the surface of the high voltage electrode 2 -TiO 2 The maximum field intensity after compounding the film is reduced to 1.82×10 8 V / m, and SiO 2 The field strength of the thin f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com