Nitrogen-doped carbon/nickel/nickel oxide nanocomposite preparation method

A nano-composite material, nitrogen-doped carbon technology, applied in the field of energy storage materials, can solve the problems of many process preparation steps, low specific capacitance of the composite, unfavorable material application, long time consumption, etc., and achieves broad application prospects, good rate characteristics and Cyclic stability, principle-reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

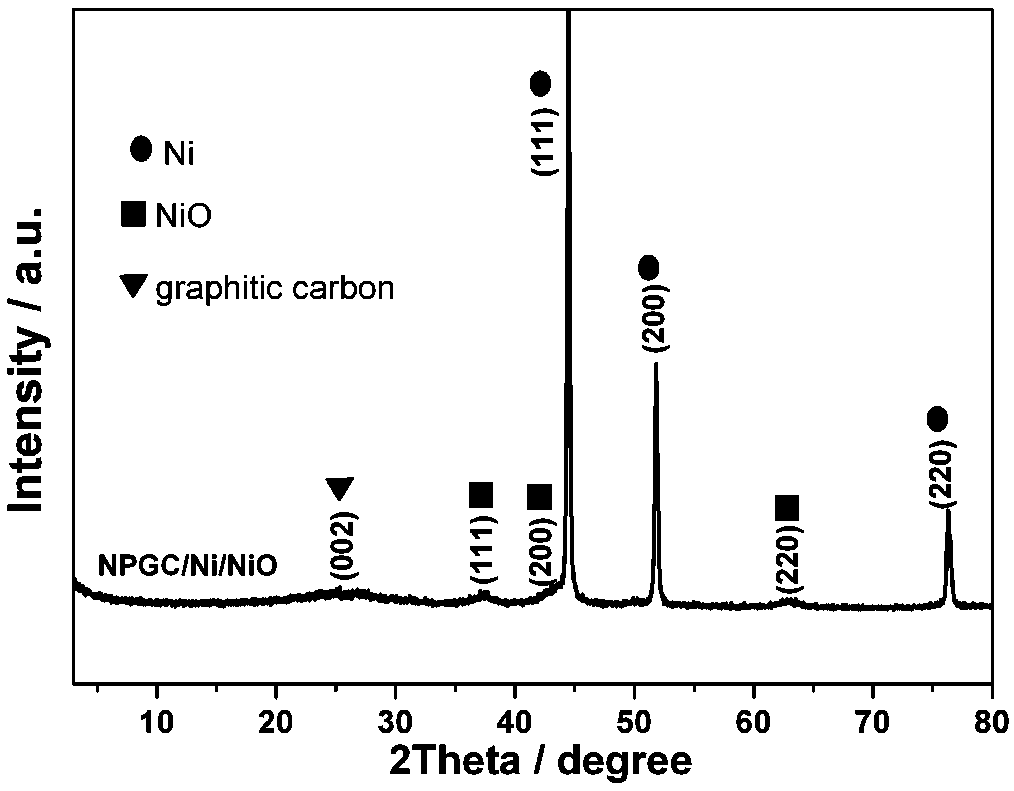

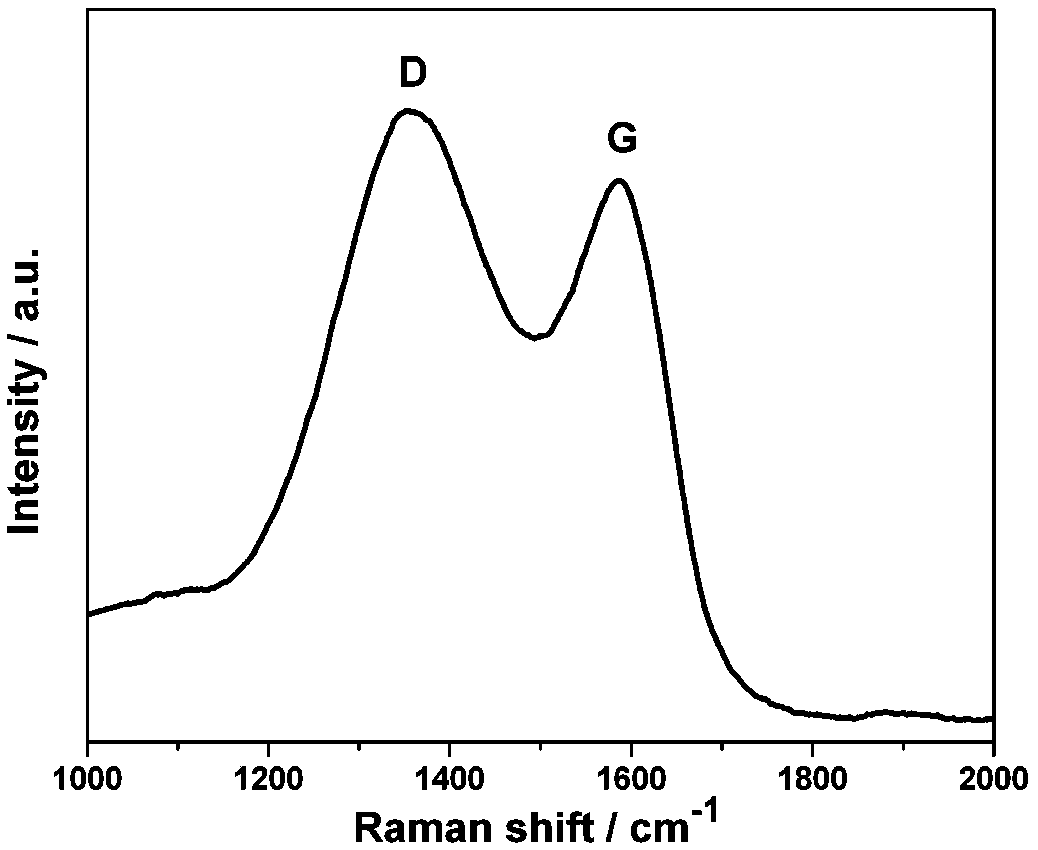

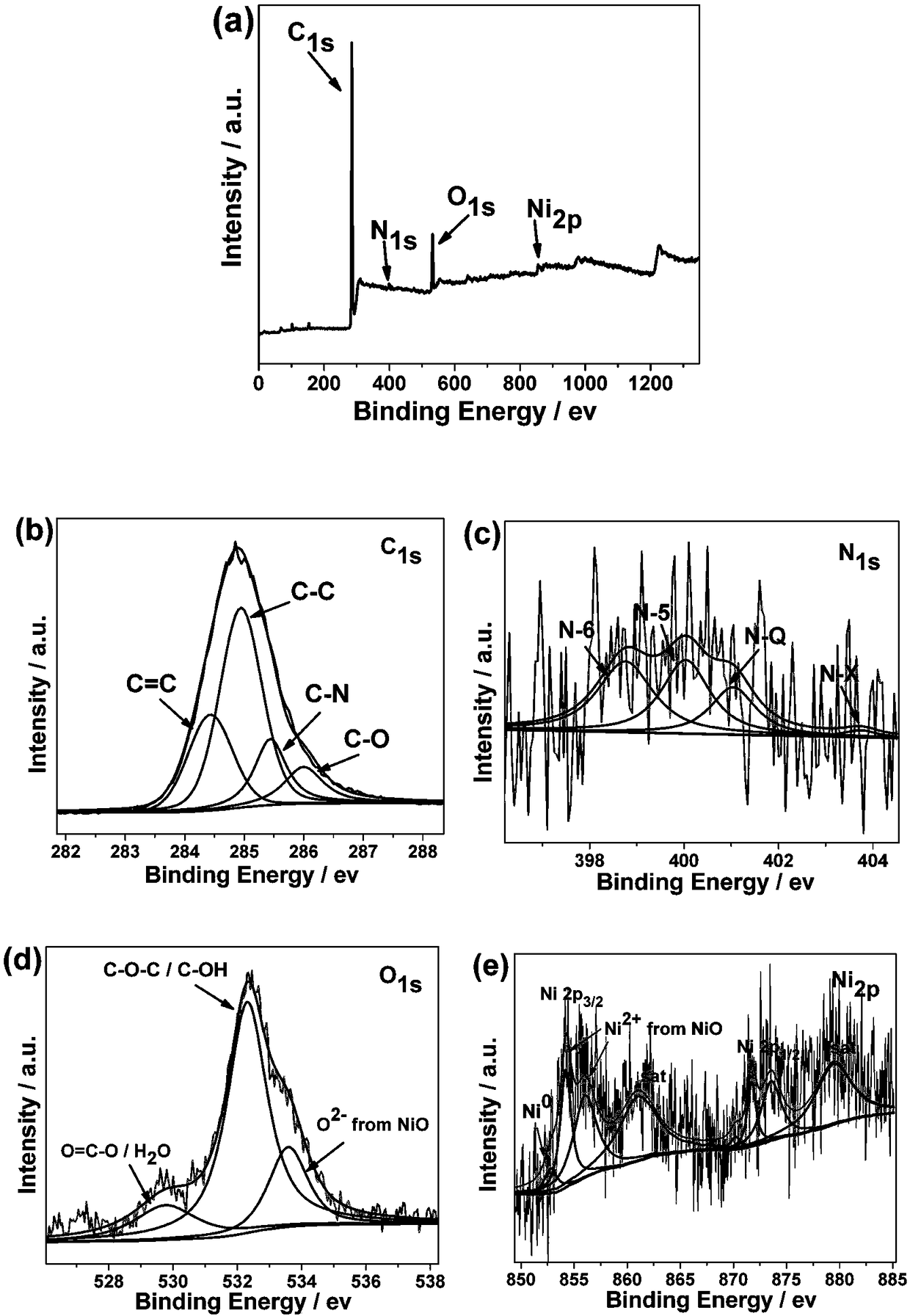

[0033] The preparation method of the three-dimensional hierarchical porous structure nitrogen-doped partially graphitized carbon / nickel / nickel oxide nanocomposite (NPGC / Ni / NiO) involved in this embodiment uses nitrogen-containing macromolecular polyacrylamide as the organic precursor, and the molecular weight 1.6 million, form a cross-linked polymer gel with resorcinol and formaldehyde and compound with inorganic nickel salt. The sample is frozen and dried with liquid nitrogen to form a three-dimensional structure cross-linked polyacrylamide / nickel salt aerogel, and then Calcining in an inert atmosphere and tempering in an air atmosphere, combined with the catalytic graphitization of nickel elements to prepare NPGC / Ni / NiO nanocomposites, the specific process of preparation includes the following steps:

[0034] (1) preparing a polymer solution: dissolving unhydrolyzed polyacrylamide in deionized water to prepare a polymer solution with a mass percentage concentration of 2%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com