Tablet candy containing haematococcus pluvialis astaxanthin for conditioning female bodies and preparation method thereof

A technology of Haematococcus pluvialis and Haematococcus pluvialis algae powder is applied in the direction of confectionery, confectionery industry, function of food ingredients, etc., and can solve the problems of application limitation, safety of chemical synthesis of astaxanthin and the like, Achieve the effect of enhancing immunity, quickly regulating intestinal microecology, and improving constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

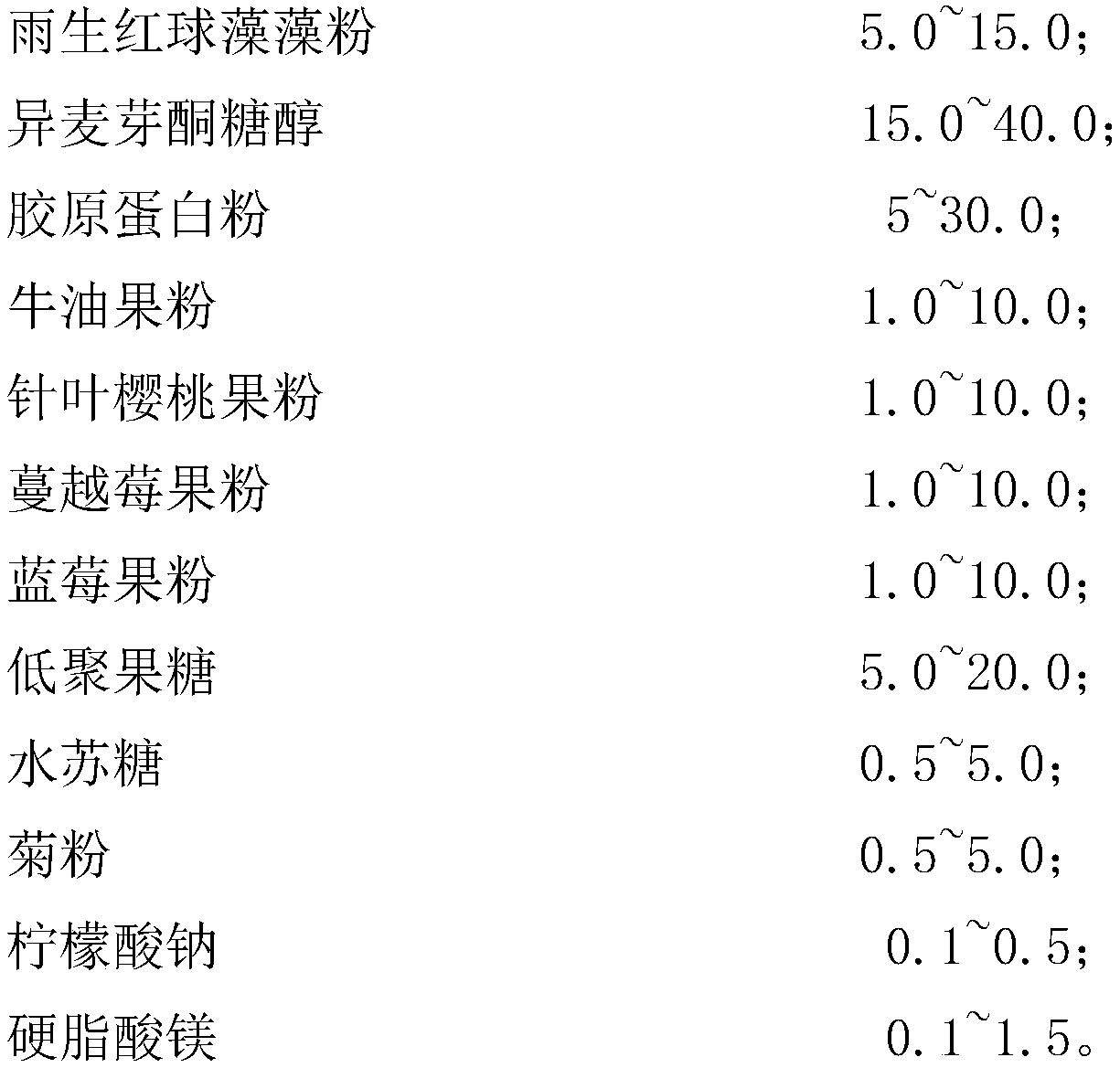

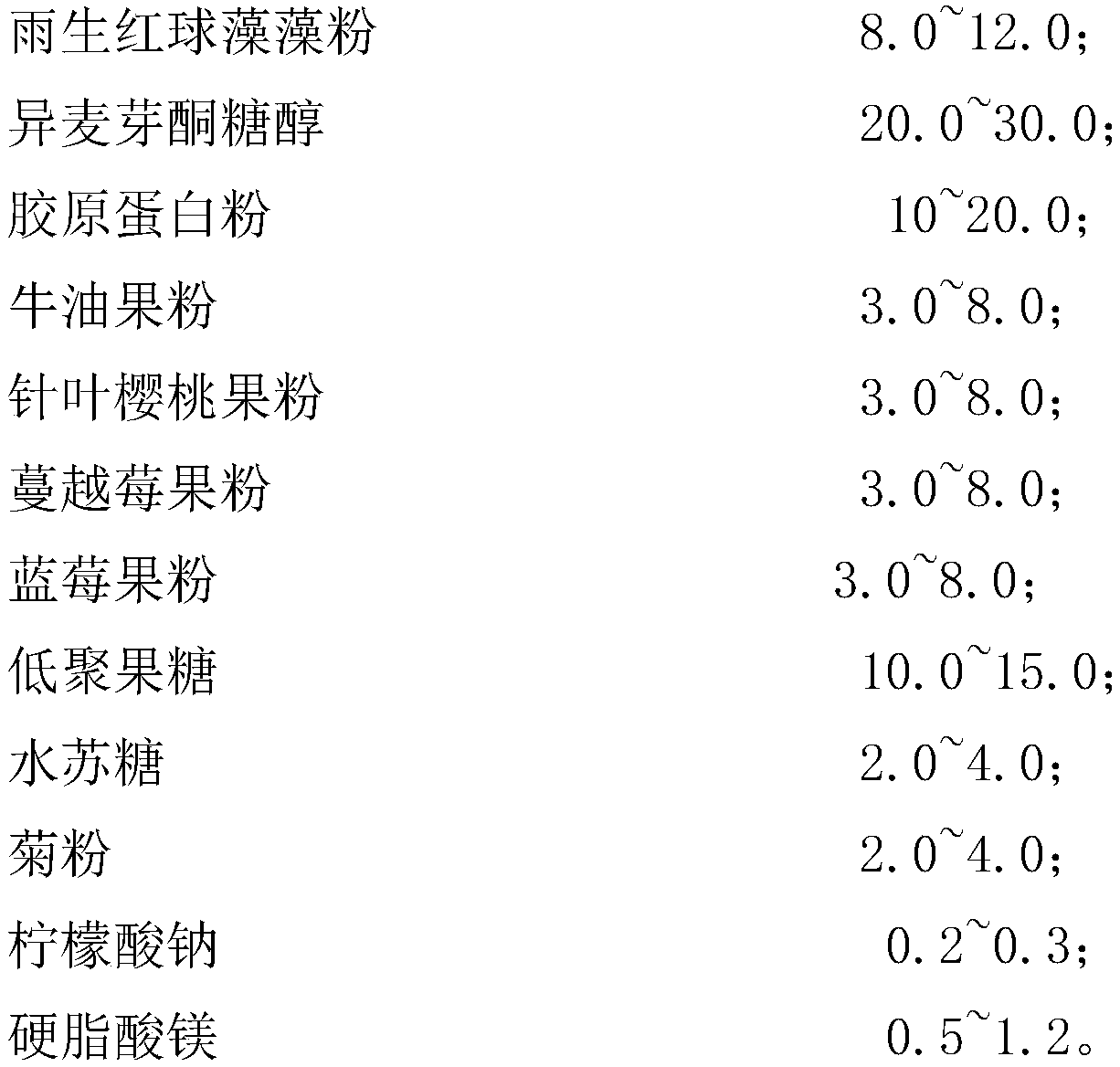

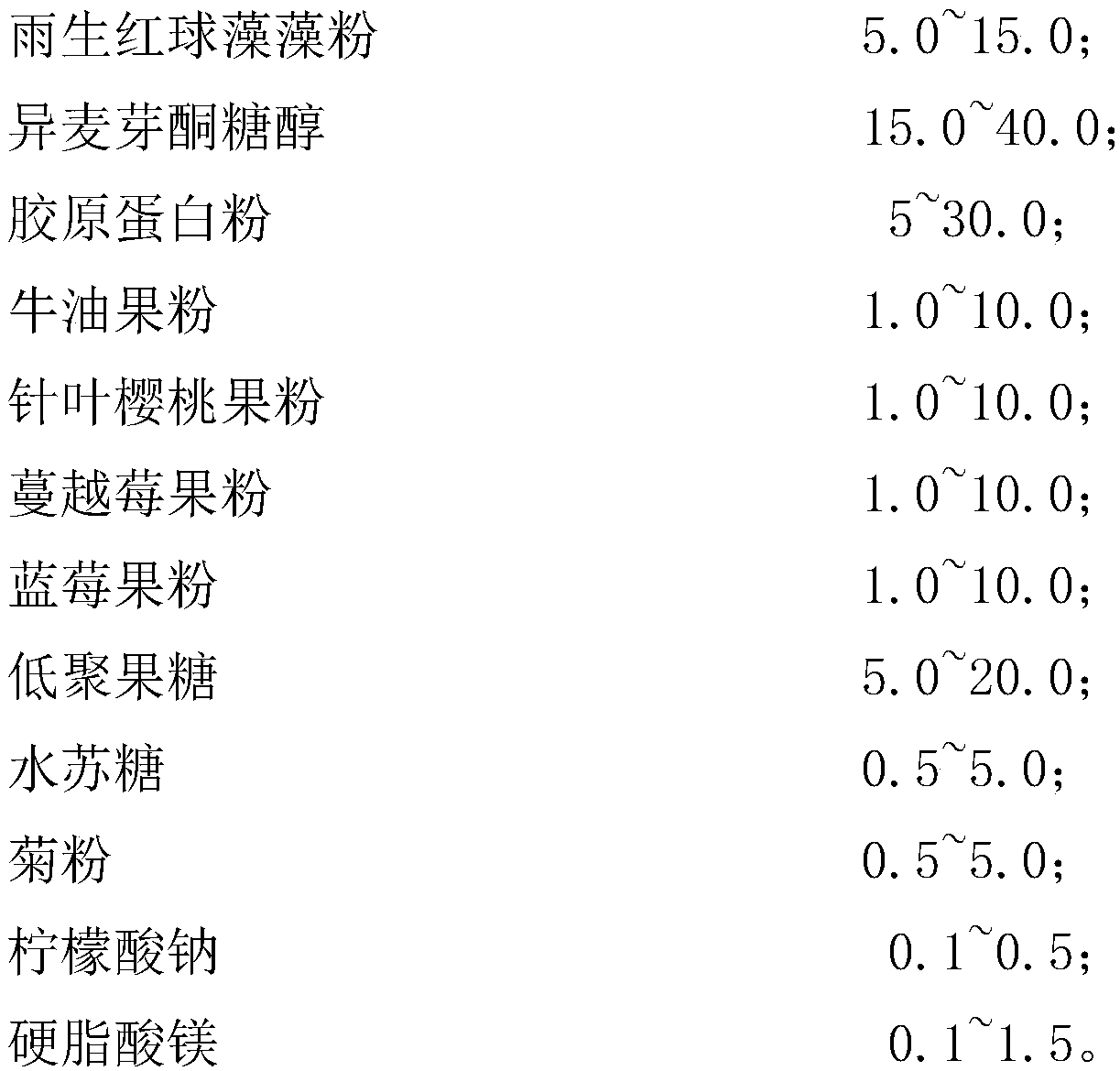

Method used

Image

Examples

Embodiment 1

[0052] Weigh 20.0g of Haematococcus pluvialis algae powder, 57.4g of isomalt, 5.0g of collagen powder, 2.0g of avocado powder, 2.0g of acerola fruit powder, 2.0g of cranberry fruit powder, 2.0g of blueberry fruit powder, Fructose-oligosaccharide 5.0g, stachyose 2.0g, inulin 2.0g, sodium citrate 0.1g, after mixing evenly, add the ethanol-water wetting agent that mass fraction is 1.0% hydroxypropyl methylcellulose, ethanol concentration 75%, about 15g, fully stirred and mixed, and granulated with a standard 20-mesh screen; put the granules into a vacuum drying oven for drying, set the temperature at 70°C, time 4.0h, and pressure -0.075MPa; the dried granules Collect, granulate with a 20-mesh standard sieve, and set aside; weigh 0.5 g of magnesium stearate and mix it with the spare granules for 10 minutes; put the mixed material into a tablet machine, adjust the tablet weight to 0.6 g, The pressure is 50KN, carry out tabletting.

Embodiment 2

[0054] Weigh 30.0g of Haematococcus pluvialis algae powder, 28.2.4g of isomalt, 10.0g of collagen powder, 5.0g of avocado powder, 5.0g of acerola fruit powder, 5.0g of cranberry fruit powder, and 5.0g of blueberry fruit powder , fructooligosaccharide 5.0g, stachyose 3.0g, inulin 3.0g, sodium citrate 0.3g, after mixing evenly, add the ethanol-water wetting agent that mass fraction is 2.0% hydroxypropyl methylcellulose, ethanol The concentration is 70%, about 20g, fully stirred and mixed, and granulated with a standard screen of 20 mesh; put the granules into a vacuum drying oven for drying, set the temperature at 65°C, time for 5.0h, and pressure -0.075MPa; Collect the granules, granulate them with a 20-mesh standard sieve, and set them aside; weigh 0.5g of magnesium stearate and mix them with the spare granules for 10 minutes; put the mixed materials into the tablet machine, and adjust the tablet weight to 0.5g , the pressure is 60KN, for tableting.

Embodiment 3

[0056] 1) preparing a mass fraction of 0.5% hydroxypropyl methylcellulose wetting agent;

[0057] 2) Weigh 5.0 parts by weight of Haematococcus pluvialis algae powder, 15.0 parts by weight of isomalt, 5 parts by weight of collagen powder, 1.0 parts by weight of avocado powder, 1.0 parts by weight of acerola fruit powder, 1.0 parts by weight of cranberry fruit powder, 1.0 parts by weight of blueberry fruit powder, fructooligosaccharides of 5.0 parts by weight, stachyose of 0.5 parts by weight, inulin of 0.5 parts by weight, sodium citrate of 0.1 parts by weight, all over 80 Mesh standard sieve, after mixing evenly, add hydroxypropyl methylcellulose wetting agent, the consumption of hydroxypropyl methylcellulose wetting agent is 10 parts by weight, mix uniformly;

[0058] 3) Granulate the uniformly mixed material;

[0059] 4) Put the prepared particles into a vacuum oven for drying;

[0060] 5) Collect the dried particles and carry out granulation;

[0061] 6) Weigh 0.1 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com