Preparation method for injectable poly(L-lactic acid) microsphere

A technology of L-polylactic acid and microspheres, which is applied in the field of medical cosmetic materials, can solve problems such as poor redissolving and dispersibility of polylactic acid microspheres, and achieve the effect of good effect and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve PLLA with an intrinsic viscosity of 1.5g / dL in chloroform to form a solution with a concentration of 1g / L; dissolve sodium carboxymethylcellulose and mannitol (mass ratio 1:20) with a molecular weight of 500,000Da in distilled water , dubbed a solution with a concentration of 0.5%. The chloroform solution of PLLA was slowly added dropwise to the sodium carboxymethylcellulose / mannitol aqueous solution under stirring, and the volume ratio of the two solutions was 1:100. Stirring is continued for 12 hours, and the mixed solution is vacuumed by an oil pump for 5 hours, and then the solution is freeze-dried to obtain injectable poly-L-lactic acid microspheres; the yield of the injectable poly-L-lactic acid microspheres is 80%.

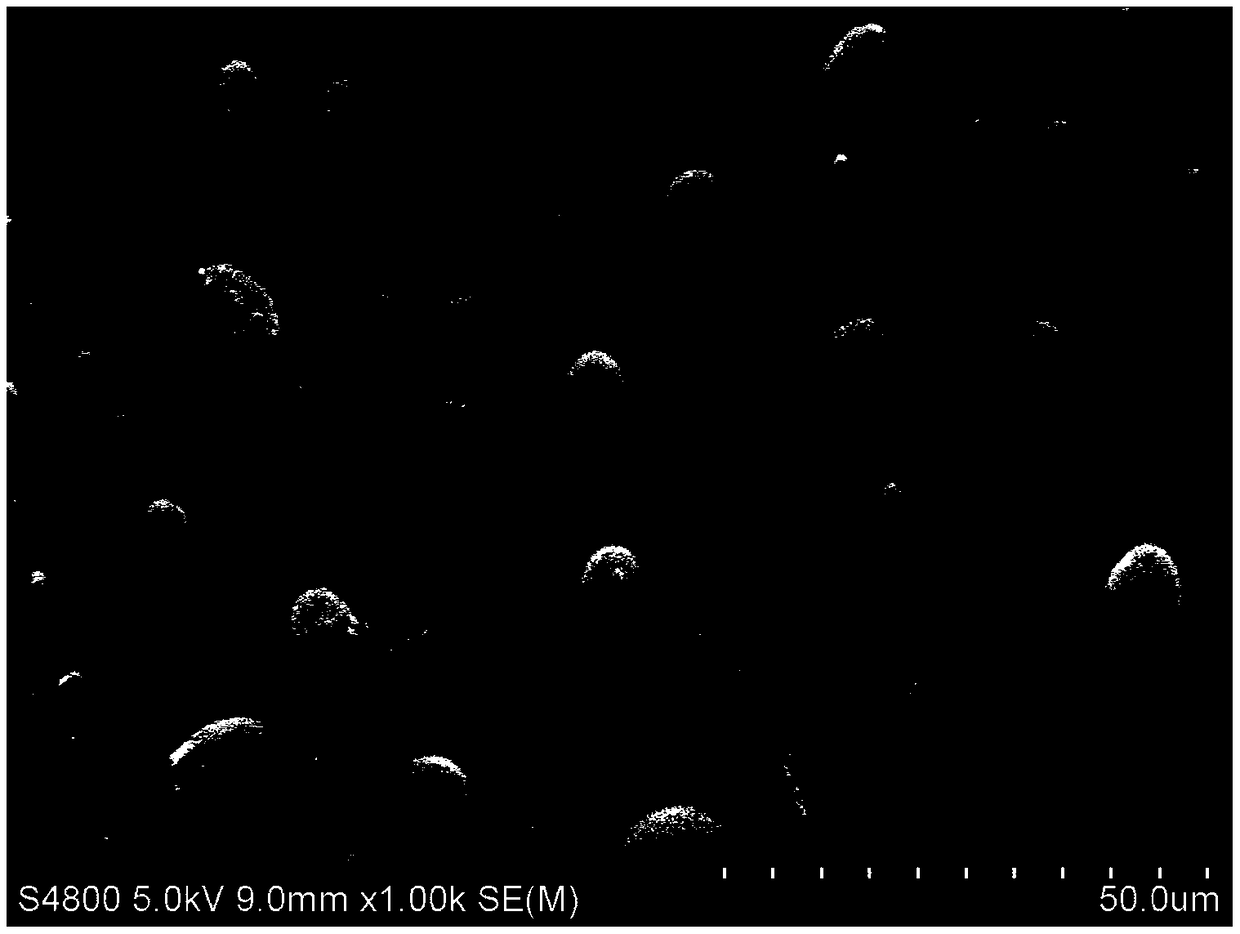

[0020] Dissolve the freeze-dried poly-L-lactic acid microspheres in water, and after the water is air-dried, obtain its scanning electron micrograph, as shown in figure 1 , It can be seen that the L-polylactic acid microspheres prepared in ...

Embodiment 2

[0022] Dissolve PLLA with an intrinsic viscosity of 0.1 g / dL in chloroform to form a solution with a concentration of 100 g / L. Sodium carboxymethyl cellulose with a molecular weight of 5000 Da and mannitol (20:1 by mass ratio) were dissolved in distilled water to prepare a solution with a concentration of 5 wt%. The chloroform solution of PLLA was slowly added dropwise to the sodium carboxymethylcellulose / mannitol aqueous solution under stirring, and the volume ratio of the two solutions was 1:5. Stirring was continued for 36 hours, and the mixed solution was vacuum pumped by an oil pump for 3 hours, and then the solution was freeze-dried to obtain injectable poly-L-lactic acid microspheres; the yield of the injectable poly-L-lactic acid microspheres was 73%.

[0023] After it was freeze-dried, it was dissolved in water, and the obtained scanning electron micrograph and figure 1 similar.

Embodiment 3

[0025] Dissolve PLLA with an intrinsic viscosity of 0.8 g / dL in chloroform to form a solution with a concentration of 10 g / L. Sodium carboxymethyl cellulose with a molecular weight of 100,000 Da and mannitol (mass ratio: 1:10) were dissolved in distilled water to prepare a solution with a concentration of 2.5 wt%. The chloroform solution of PLLA was slowly added dropwise into the aqueous solution of sodium carboxymethylcellulose / mannitol under stirring, and the volume ratio of the two solutions was 1:20. Stirring is continued for 48 hours, the mixed solution is vacuumed by an oil pump for 0.5 hour, and the solution is freeze-dried to obtain injectable poly-L-lactic acid microspheres; the yield of the injectable poly-L-lactic acid microspheres is 90%.

[0026] After it was freeze-dried, it was dissolved in water, and the obtained scanning electron micrograph and figure 1 similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com