Method for preparing rod-shaped ferroferric oxide particle-carrying biochar composite material

A technology of ferric tetroxide and composite materials is applied in the field of preparation of biochar composite materials, which can solve the problems of easy agglomeration of particles and long consumption time, and achieve the effects of enhancing adsorption capacity, enhancing absorption rate and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

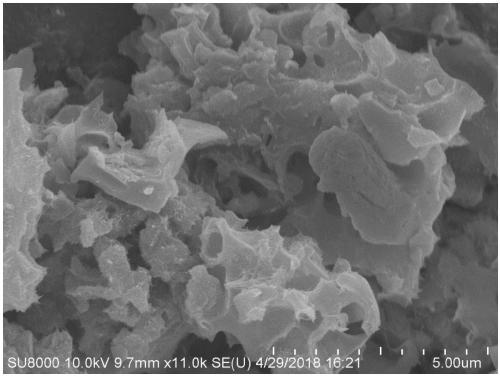

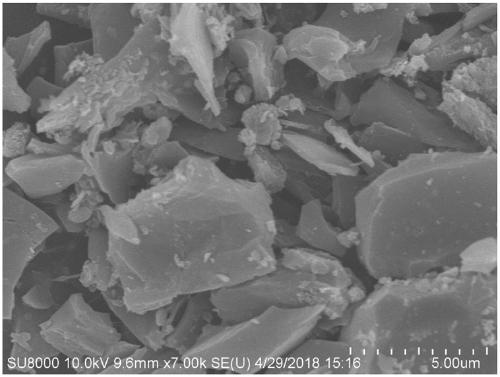

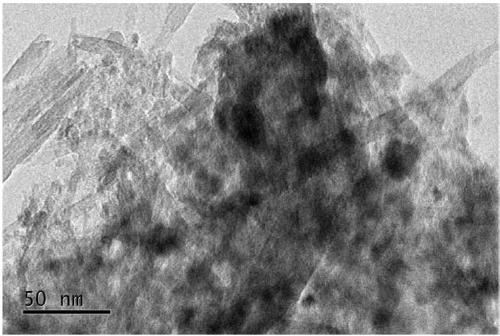

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment one: the preparation method of rod-shaped iron ferric oxide particle-loaded biochar composite material in this embodiment comprises the following steps:

[0033] 1. Electrochemically assisted modification and electrolysis of the mixture solution:

[0034] Shearing and pulverizing the biomass material, washing with distilled water for 3 to 10 times, drying at a temperature of 60°C to 90°C, and passing through a 20-mesh sieve to 100-mesh sieve after drying to obtain a finely divided powder of the biomass material;

[0035] Mix the finely divided biomass material powder with the metal salt solution to obtain a mixed solution, apply a voltage to the mixed solution with a DC stabilized power supply, stir and react at a stirring speed of 500r / min-1500r / min for 3min-15min, and obtain a solid-liquid mixture, Finally, the solid-liquid mixture is dried under vacuum conditions at 70°C to 100°C to obtain a dry mixture;

[0036] Wherein the concentration of the ...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that the biomass material described in step 1 is one or a mixture of corn stalks, rice husks, sawdust, and bamboo stalks. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal salt solution described in step 1 is an iron salt solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com