Polycarboxylate water reducer derived from environmentally friendly and odorless raw materials and its preparation method and application

A technology of polycarboxylate and water reducer, applied in polycarboxylate water reducer derived from environmentally friendly and odorless raw materials and its preparation and application fields, can solve problems such as unbearable odor, achieve convenient operation, good slump retention effect, High water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a preparation method of the polycarboxylate water reducer quickly synthesized from odorless and environmentally friendly small materials, which comprises the following steps: under stirring conditions, ammonium persulfate is added to the mixture A, and then the solution B is added dropwise , solution C, and solution D, carry out polymerization reaction, after aging for a period of time, adjust the solid content to 30wt% ~ 50wt% with water, which is a polycarboxylate water reducer quickly synthesized from a tasteless and environmentally friendly small material;

[0064] The mixture A is obtained by mixing unsaturated polyether, sodium hypophosphite and water;

[0065] The solution B is obtained by mixing L-ascorbic acid, E51, sodium formaldehyde sulfoxylate and water;

[0066] The solution C is obtained by mixing hydrogen peroxide and water;

[0067] The solution D is obtained by mixing acrylic acid, sodium methacrylate and water.

...

Embodiment 1

[0089] (1) Preparation before polymerization:

[0090] Preparation of mixture A: Weigh 100 parts by weight of methallyl polyoxyethylene ether with a number average molecular weight of 2400, 50 parts by weight of water, and 1.5 parts of sodium hypophosphite, put them into a polymerization reactor, stir evenly, and keep at 25°C ,spare;

[0091] Preparation of solution B: Weigh 1.0 parts by weight of L-ascorbic acid, 0.9 parts by weight of sodium formaldehyde sulfoxylate and 23 parts by weight of water, stir evenly, and prepare dropwise;

[0092] Preparation of solution C: weigh 2.0 parts by weight of hydrogen peroxide and 20 parts by weight of water, stir evenly, and prepare to add dropwise;

[0093] Preparation of solution D: Weigh 24 parts by weight of acrylic acid and 1 part by weight of sodium methacryl sulfonate for dropwise addition;

[0094] (2) Polymerization: In step (1) the polymerization reactor that has been put into mixture A, start stirring, when the temperature ...

Embodiment 2~5

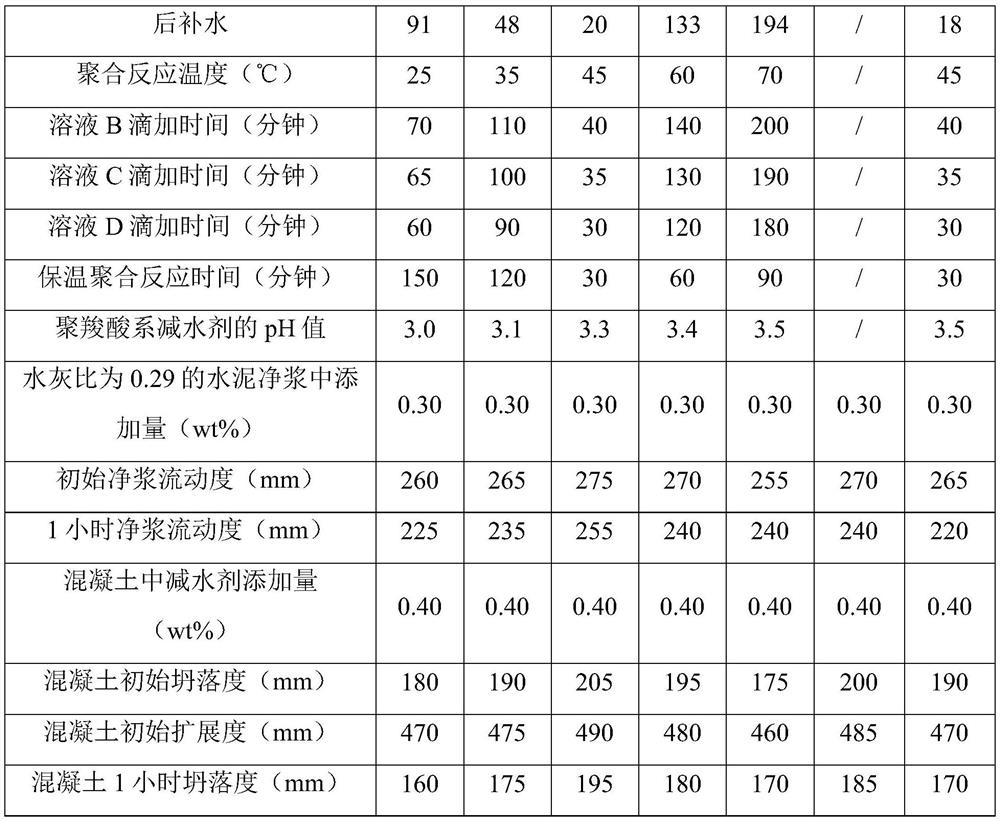

[0098] The preparation methods of Examples 2-5 are the same as those of Example 1, and the differences are specifically marked in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com