Anti-ozone and ultraviolet-resistant non-toxic ceramic anticorrosive coating and preparation method thereof

A UV-resistant and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve problems such as unfavorable environmental protection, and achieve excellent waterproof, good resistance, wear resistance and Good dirt performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0053] An anti-ozone anti-ultraviolet and non-toxic ceramic anti-corrosion coating comprises A component and B component, which can be coated after mixing the A component and the B component during use.

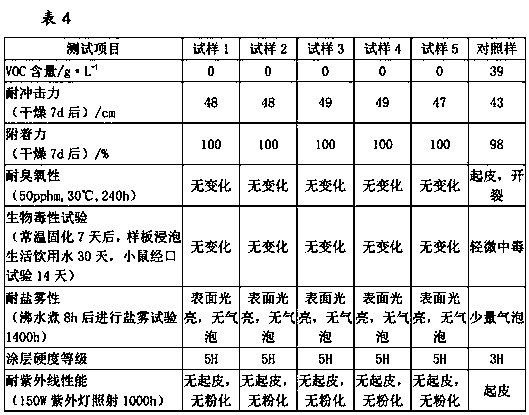

[0054] In parts by weight, the content of each component in the A component is as shown in Table 1:

[0055]

[0056] The fumed silica used as an anti-sedimentation agent in each embodiment can also be replaced by organic bentonite; the silicone-modified epoxy resin used is a commercially available common silicone-modified epoxy resin.

[0057] The filler used in each embodiment is one or more of quartz powder, talc powder, ceramic powder, and mica powder. The concrete material composition of filler used among the embodiment 1-5 is as shown in table 2:

[0058]

[0059] The flaky fiber powder used in each embodiment is flaky polyethylene powder with a maximum particle size ≤ 15 μm; the liquid polysulfide rubber used can also be replaced by liquid nitrile rubber.

[0060...

Embodiment 6

[0067] A preparation method for ozone-resistant, ultraviolet-resistant and non-toxic ceramic anti-corrosion coating, specifically comprising the following steps:

[0068] Step 1. Weigh 45 parts of silicone-modified epoxy resin and 8 parts of polyglycidyl ether according to parts by weight, mix and stir evenly to obtain mixed material 1; the silicone-modified epoxy resin used is the same as that in Example 1;

[0069] Step 2: Add 12 parts of pigments, 8 parts of fillers, 0.3 parts of fumed silica, 0.8 parts of flake polyethylene fiber powder, 1.8 parts of softener, and silane coupling agent to the mixed material 1 in sequence. 0.4 parts are mixed and stirred evenly to obtain the mixed material 2; the material selection of softener, silane coupling agent, pigment and filler is the same as that of Example 1;

[0070] Step 3: Grinding the mixed material 2 to a fineness of less than 15 μm with a grinder, filtering, and packaging to obtain component A;

[0071] Step 4. According to...

Embodiment 7

[0073] A preparation method for ozone-resistant, ultraviolet-resistant and non-toxic ceramic anti-corrosion coating, specifically comprising the following steps:

[0074] Step 1. Weigh 47 parts of silicone-modified epoxy resin and 8 parts of polyglycidyl ether according to parts by weight, mix and stir evenly to obtain a mixture material 1; the silicone-modified epoxy resin used is the same as that in Example 2;

[0075] Step 2: Add 14.5 parts of pigments, 8 parts of fillers, 0.4 parts of fumed silica, 0.9 parts of flake polyethylene fiber powder, 1.9 parts of softener, and silane coupling agent to the mixed material 1 in sequence. 0.4 parts are mixed and stirred evenly to obtain the mixed material 2; the material selection of softener, silane coupling agent, pigment and filler is the same as that of Example 2;

[0076] Step 3: Grinding the mixed material 2 to a fineness of less than 15 μm with a grinder, filtering, and packaging to obtain component A;

[0077] Step 4. Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com