Ice melting agent for deicing power transmission lines, and preparation method thereof

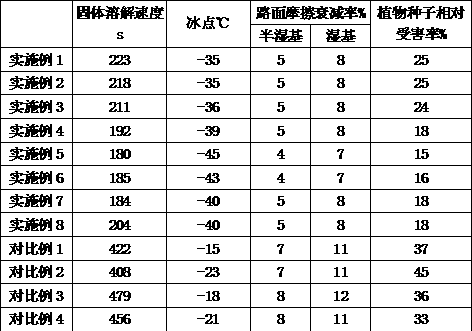

A transmission line and ice-melting agent technology, which is applied in the installation of chemical instruments and methods, electrical components, cables, etc., can solve the problems of slow melting rate, high freezing point, poor melting and deicing effect, etc., to reduce damage, The effect of excellent comprehensive performance and high melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A deicing agent for power transmission lines is made of the ingredients shown in Table 1, and the modified multi-walled carbon nanotubes are made of the ingredients shown in Table 2.

[0032] Wherein, the massfraction of described sodium hydroxide solution is 4%.

[0033] The mixed acid solution is a mixture of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid: concentrated nitric acid is 2:1, the concentration of concentrated sulfuric acid is 98%, and the concentration of concentrated nitric acid is 68%.

[0034] The corrosion inhibitor is sodium gluconate.

[0035] The preparation method of the modified multi-walled carbon nanotubes comprises the following steps:

[0036] Step 1: immerse the multi-walled carbon nanotubes in sodium hydroxide solution for 8 hours, filter the first microporous membrane with a pore size of 0.6-0.8 μm, take the solid product and dry it in an oven at 80°C for 2 hours, Place in mixed ac...

Embodiment 2

[0045] A deicing agent for transmission line deicing, made of the ingredients shown in Table 1, the ingredients and their dosage in the modified multi-walled carbon nanotubes are the same as in Example 1.

[0046] Wherein, the massfraction of described sodium hydroxide solution is 4%.

[0047] The mixed acid solution is a mixture of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid: concentrated nitric acid is 2.2:1, the concentration of concentrated sulfuric acid is 98%, and the concentration of concentrated nitric acid is 68%.

[0048] The corrosion inhibitor is thiourea.

[0049] The preparation method of the modified multi-walled carbon nanotubes is the same as in Example 1.

[0050] The preparation method of the deicing agent for a transmission line deicing is the same as in Example 1.

Embodiment 3

[0052] A deicing agent for power transmission lines is made of the ingredients shown in Table 1, and the modified multi-walled carbon nanotubes are made of the ingredients shown in Table 2.

[0053] Wherein, the mass fraction of the sodium hydroxide solution is 4.5%.

[0054] The mixed acid solution is a mixture of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid: concentrated nitric acid is 2.5:1, the concentration of concentrated sulfuric acid is 98%, and the concentration of concentrated nitric acid is 68%.

[0055] The corrosion inhibitor is aluminum sulfate.

[0056] The preparation method of the modified multi-walled carbon nanotubes comprises the following steps:

[0057] Step 1: immerse the multi-walled carbon nanotubes in sodium hydroxide solution for 9 hours, filter the first microporous membrane with a pore size of 0.6-0.8 μm, take the solid product and dry it in an oven at 80°C for 2 hours, Place in mixed aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com