Dore silver electro-refining process

An electrolytic refining and process technology, applied in the field of metallurgy, can solve the problems of large capital occupation, environmental pollution, low electrolysis speed, etc., and achieve the effect of good promotion and demonstration, reducing production costs and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

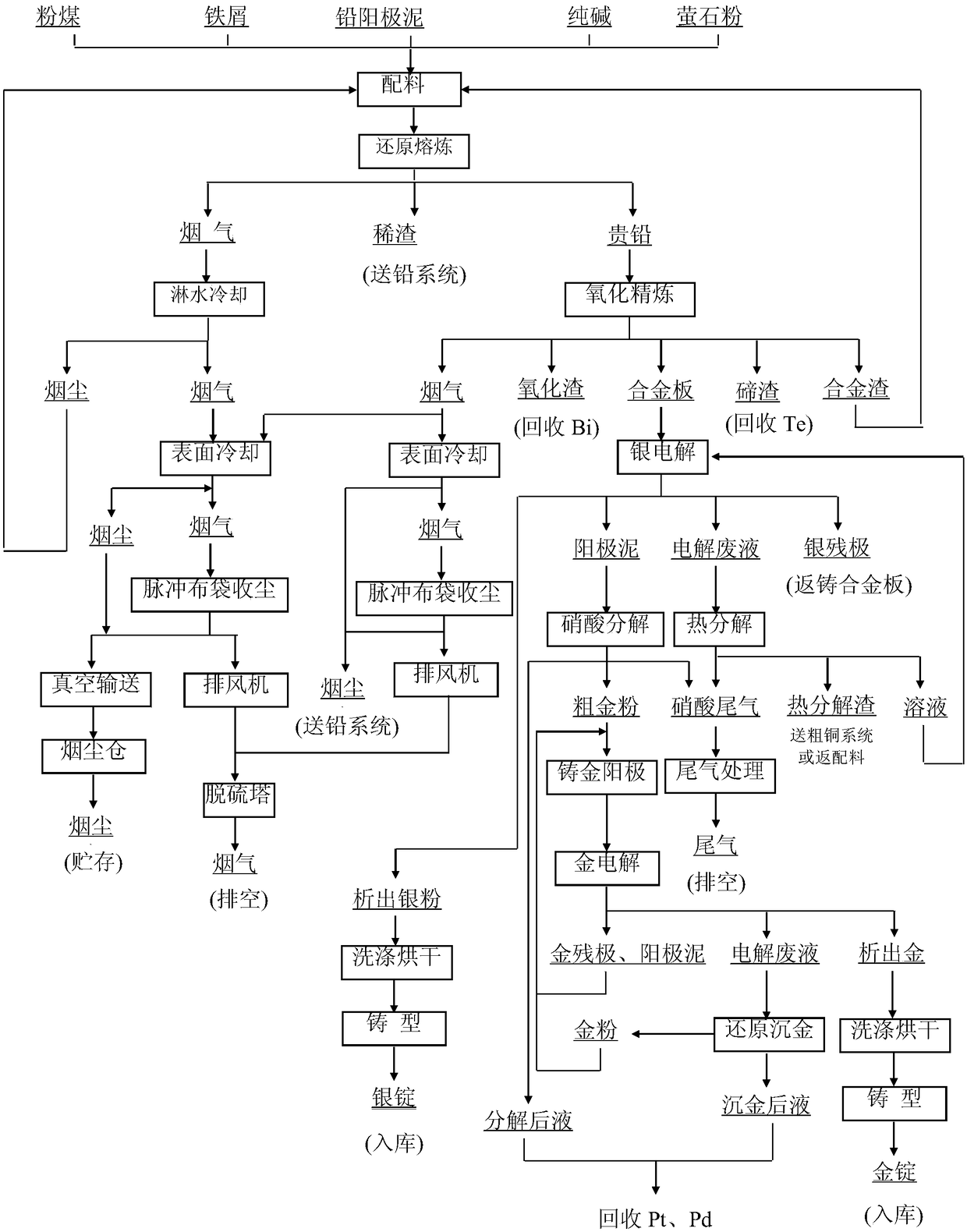

Method used

Image

Examples

Embodiment 1

[0084] A crude silver electrolytic refining process specifically comprises the following steps:

[0085] Step 1: Put the silver powder into the enamel reaction kettle to react with nitric acid, filter, and vacuum filter the silver nitrate solution to the silver nitrate high storage tank for later use;

[0086] Step 2: Slowly add caustic soda to the silver nitrate solution filtered in step 1, stop when the internal pH value of the reaction system reaches 14, continue stirring for 20 minutes, vacuum filter, and pump the filtrate into the waste liquid storage tank;

[0087]Step 3: Add the silver hydroxide obtained in step 2 into the electrolyte purification reaction kettle, add waste electrolyte in the purification reaction kettle until the pH of the system is 5.5, suction filter, and add appropriate amount of pure water and nitric acid in the filtrate to obtain Silver electrolyte, and the silver ion concentration of the prepared electrolyte is 125g / L;

[0088] Step 4: Hang the ...

Embodiment 2

[0090] Compared with Example 1, a kind of coarse silver electrolytic refining process disclosed in this embodiment is mainly different in that: Step 1 is replaced by the following steps: put the anode slime into an enamel reactor to react with nitric acid, and vacuum filter the The dissolved silver of silver nitrate is pumped into the silver nitrate high-level storage tank, and the filter residue is returned to the gold refining workshop for processing, and other process parameters remain unchanged.

Embodiment 3

[0092] Compared with Example 1, the crude silver electrolytic refining process disclosed in this example is mainly different in that the silver ion concentration of the electrolyte prepared in Step 3 is 135 g / L, and other process parameters remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com