Antibacterial release paper and production method thereof

A technology of release paper and isolation layer, applied in the field of release paper, can solve the problems of high price, environmental hazards, low biodegradation performance, etc., and achieve the effects of easy realization of preparation process conditions, favorable production and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

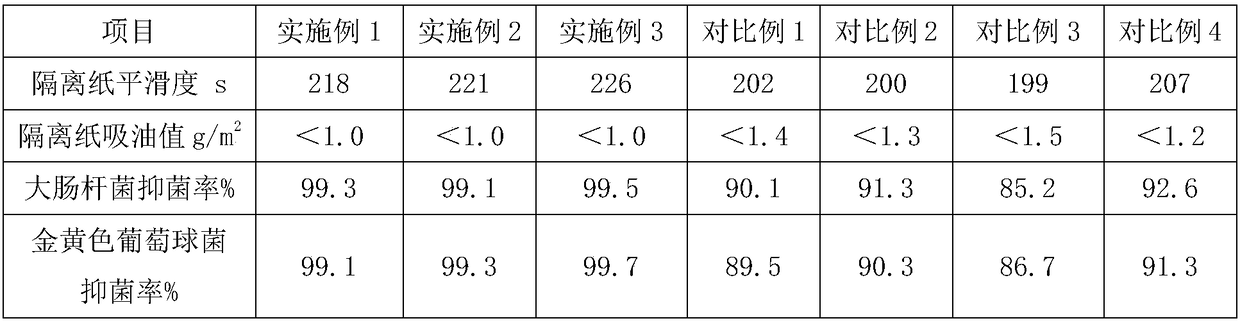

Examples

Embodiment 1

[0019] A kind of bacteriostatic release paper, described bacteriostatic release paper comprises base paper layer, pre-coat and isolation layer; Described pre-coat comprises the raw material of following parts by weight: lipoic acid 8 parts, zinc hyaluronate 6 parts , 4 parts of chitosan, 8 parts of seaweed gum, 5 parts of sodium lignosulfonate, 5 parts of butyl acetate; Described isolation layer comprises the raw material of following parts by weight: 10 parts of polyvinyl alcohol aqueous solution, benzotriazole 7 parts, ferric citrate 5 parts, castor oil polyoxyethylene ether 4 parts, disodium hydrogen phosphate 5 parts.

[0020] A preparation method for antibacterial release paper, comprising the following steps: (1) preparing a precoat: mixing chitosan and lipoic acid, adding water of 1 times the weight of the mixture, stirring and mixing to obtain mixture A; Zinc acid and sodium lignosulfonate were mixed, water of 1 times the weight of the mixture was added, and the mixtur...

Embodiment 2

[0022] A kind of bacteriostasis release paper, described bacteriostasis release paper comprises base paper layer, precoat and isolation layer; Described precoat comprises the raw material of following parts by weight: lipoic acid 13 parts, zinc hyaluronate 15 parts , 8 parts of chitosan, 15 parts of seaweed gum, 10 parts of sodium lignosulfonate, 10 parts of butyl acetate; Described isolation layer comprises the raw material of following parts by weight: 15 parts of polyvinyl alcohol aqueous solution, benzotriazole 10 parts, 8 parts of iron citrate, 6 parts of castor oil polyoxyethylene ether, 8 parts of disodium hydrogen phosphate.

[0023] A preparation method for antibacterial release paper, comprising the following steps: (1) preparing a precoat: mixing chitosan and lipoic acid, adding water 2 times the weight of the mixture, stirring and mixing to obtain mixture A; Mix zinc acid and sodium lignosulfonate, add water twice the weight of the mixture, stir and mix evenly to o...

Embodiment 3

[0025] A kind of bacteriostatic release paper, described bacteriostatic release paper comprises base paper layer, precoat and isolation layer; Described precoat comprises the raw material of following parts by weight: lipoic acid 11 parts, zinc hyaluronate 13 parts , 6 parts of chitosan, 12 parts of alginate, 9 parts of sodium lignosulfonate, 7 parts of butyl acetate. The isolation layer includes the following raw materials in parts by weight: 12 parts of polyvinyl alcohol aqueous solution, 9 parts of benzotriazole, 6 parts of ferric citrate, 5 parts of castor oil polyoxyethylene ether, and 7 parts of disodium hydrogen phosphate.

[0026] A preparation method for antibacterial release paper, comprising the following steps: (1) preparing a precoat: mixing chitosan and lipoic acid, adding water 1.6 times the weight of the mixture, stirring and mixing to obtain mixture A; Mix zinc acid and sodium lignosulfonate, add 1.2 times the weight of water to the mixture, stir and mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com