A method and application of in-situ synthesis of three-dimensional graphene-coated cubic sodium manganese ferricyanide

A technology of graphene coating and sodium manganese ferricyanide, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of lattice defect restriction application, poor cycle and rate performance, low electronic conductivity, etc., and achieve cycle And the effects of good rate stability, less uniform coating, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

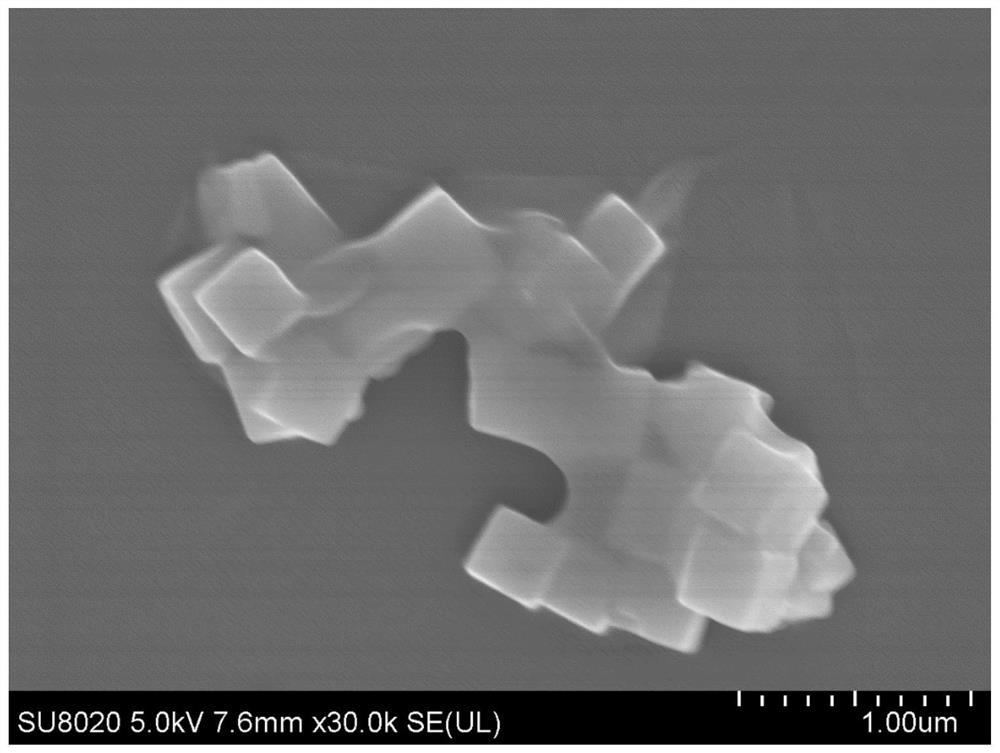

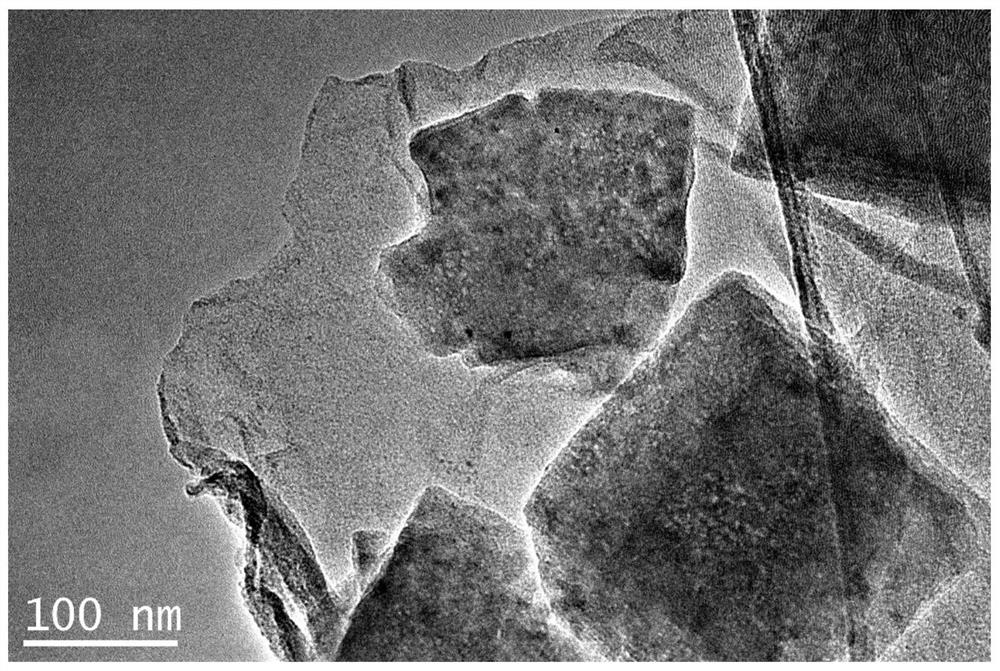

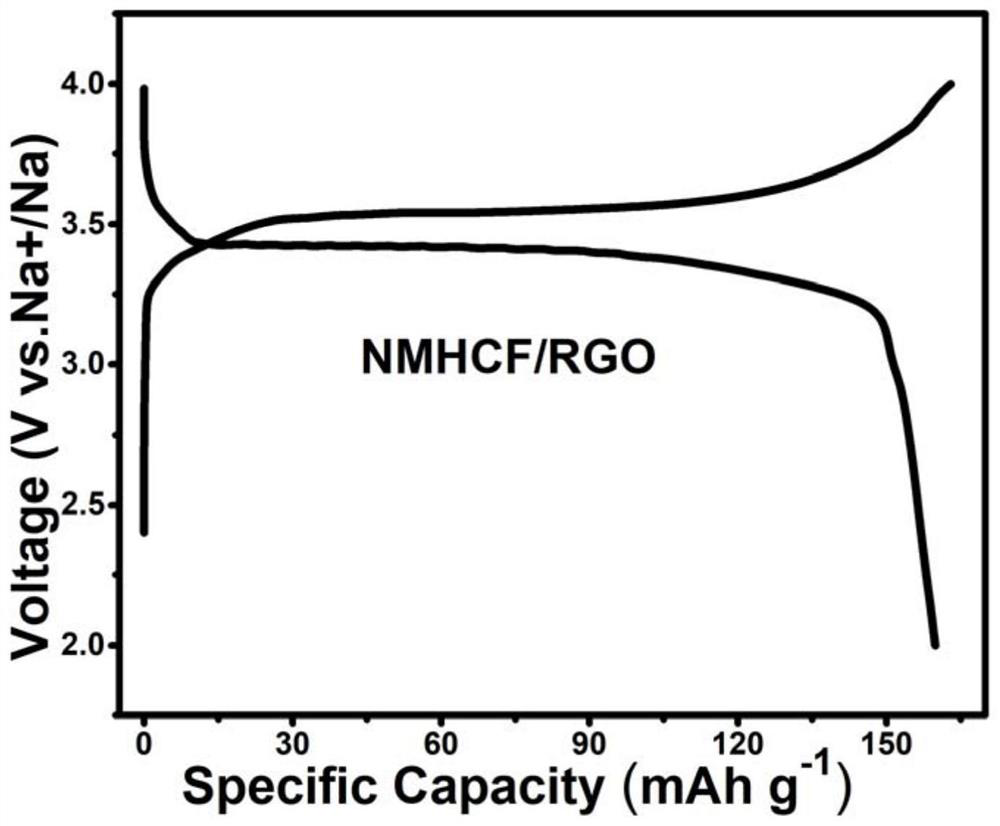

[0033] In the present embodiment, the preparation method of PVP-assisted in-situ synthesis of three-dimensional graphene-coated cube-shaped sodium manganese ferricyanide is as follows:

[0034] 1. First, graphene oxide is prepared by the improved Hummers method, washed with deionized water until neutral, and then freeze-dried at -50°C to obtain three-dimensional large specific surface area graphene oxide, which is then sealed in an alumina crucible and placed in a 1000 ℃ Reduction in muffle furnace for 1 minute to obtain redox graphene with developed three-dimensional specific surface area;

[0035] 2. Take 0.2g of the three-dimensional large specific surface area redox graphene obtained in step 1, and ultrasonically disperse it in 100ml of ionized water;

[0036] 3. Mix 0.05mol of sodium ferricyanide (Na 4 Fe(CN) 6 ) and 14g sodium chloride were added in the above-mentioned graphene aqueous solution, stirred at room temperature for 2h;

[0037] 4. Mix 0.05mol of manganese ...

Embodiment 2

[0039] In the present embodiment, the preparation method of PVP-assisted in-situ synthesis of three-dimensional graphene-coated cube-shaped sodium manganese ferricyanide is as follows:

[0040] 1. First, graphene oxide is prepared by the improved Hummers method, washed with deionized water until neutral, and then freeze-dried at -50°C to obtain three-dimensional large specific surface area graphene oxide, which is then sealed in an alumina crucible and placed in a 1000 ℃ Reduction in muffle furnace for 1 minute to obtain redox graphene with developed three-dimensional specific surface area;

[0041] 2. Take 0.2g of the three-dimensional large specific surface area redox graphene obtained in step 1, and ultrasonically disperse it in 100ml of ionized water;

[0042] 3. Mix 0.05mol of sodium ferricyanide (Na 4 Fe(CN) 6 ) and 14g sodium chloride were added in the above-mentioned graphene aqueous solution, stirred at room temperature for 2h;

[0043] 4. Mix 0.05mol of manganese ...

Embodiment 3

[0045] In the present embodiment, the preparation method of PVP-assisted in-situ synthesis of three-dimensional graphene-coated cube-shaped sodium manganese ferricyanide is as follows:

[0046] 1. First, graphene oxide is prepared by the improved Hummers method, washed with deionized water until neutral, and then freeze-dried at -50°C to obtain three-dimensional large specific surface area graphene oxide, which is then sealed in an alumina crucible and placed in a 1000 ℃ Reduction in muffle furnace for 1 minute to obtain redox graphene with developed three-dimensional specific surface area;

[0047] 2. Take 0.2g of the three-dimensional large specific surface area redox graphene obtained in step 1, and ultrasonically disperse it in 100ml of ionized water;

[0048] 3. Mix 0.05mol of sodium ferricyanide (Na 4 Fe(CN) 6 ) and 14g sodium chloride were added in the above-mentioned graphene aqueous solution, stirred at room temperature for 2h;

[0049] 4. Mix 0.05mol of manganese ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com