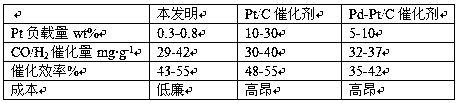

A catalyst with ultra-low platinum content for fuel cell and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of controlling surface layer thickness, reducing catalyst activity, and high operational requirements, achieving high battery performance, reducing the dependence on precious metals, and excellent catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

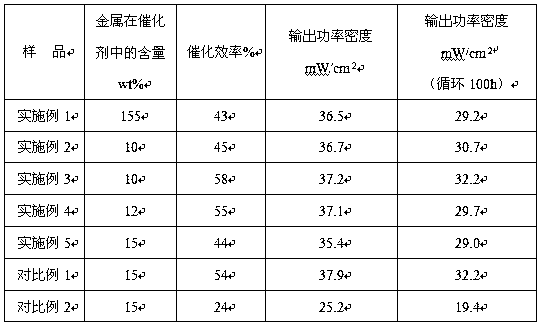

Examples

Embodiment 1

[0034] (1) Weigh 0.6 parts of nickel sulfate, 0.3 parts of silver nitrate, 0.2 parts of copper sulfate, 8 parts of dilute sulfuric acid, 1.5 parts of potassium chloroplatinate, 6 parts of oleylamine, 22 parts of trioctylphosphine, N,N - 55 parts of dimethylformamide, appropriate amount of deionized water for later use;

[0035] (2) Dissolve silver nitrate in deionized water to obtain a silver ion solution with a molar concentration of 0.2mol / L, then mix nickel sulfate, oleylamine and trioctylphosphine evenly, start heating at room temperature, and raise the temperature to 180 °C , keep warm for 3min to form a suspension, add dropwise silver nitrate solution, stir evenly, keep warm for 0.5h, and form a composite suspension;

[0036] (3) Place the composite suspension in an airflow with an air velocity of 0.5m / min, cool the suspension to room temperature, and then use a centrifuge to centrifuge the suspension at a speed of 600rpm. 5min, remove the lower layer of precipitation, ...

Embodiment 2

[0042] (1) Weigh 0.65 parts of manganese acetate, 0.33 parts of palladium sulfate, 0.18 parts of copper sulfate, 7 parts of dilute sulfuric acid, 0.7 parts of potassium chloroplatinate, 12 parts of oleylamine, 18 parts of trioctylphosphine, N, 70 parts of N-diethylformamide, appropriate amount of deionized water for later use;

[0043] (2) Dissolve palladium sulfate in deionized water to obtain a palladium ion solution with a molar concentration of 2.5mol / L, then mix manganese acetate, oleylamine and trioctylphosphine evenly, start heating at room temperature, and raise the temperature to 230 °C , insulated for 2.7min to form a suspension, then dropwise add palladium sulfate solution, stir evenly, and insulate for 0.7h to form a composite suspension;

[0044] (3) Place the composite suspension in an airflow with an air velocity of 2m / min, cool the suspension to room temperature, and then use a centrifuge to centrifuge the suspension at a speed of 950rpm for 5 minutes. , obtai...

Embodiment 3

[0050] (1) Weigh 0.7 parts of chromium acetate, 0.4 parts of silver fluoride, 0.1 parts of copper sulfate, 6 parts of dilute sulfuric acid, 1.3 parts of potassium chloroplatinate, 15 parts of oleylamine, 30 parts of trioctylphosphine, N , 60 parts of mixed solvent of N-dimethylformamide and N,N-diethylformamide, appropriate amount of deionized water for use;

[0051] (2) Dissolve silver fluoride in deionized water to obtain a noble metal ion solution with a molar concentration of 1.5 mol / L, then mix the transition metal salt with oleylamine and trioctylphosphine evenly, start heating at room temperature, and heat up to 270 ℃, keep warm for 2 minutes to form a suspension, then add dropwise the precious metal salt solution, stir evenly, keep warm for 1.5 hours to form a composite suspension;

[0052] (3) Place the composite suspension in an airflow with an air velocity of 1.5m / min, cool the suspension to room temperature, and then use a centrifuge to centrifuge the suspension at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com