A lithium-aluminum double-ion rechargeable battery

A rechargeable battery and dual-ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large ionic radius, difficult ion insertion, and difficult breakthrough, and achieve excellent performance, increase energy density, and effective charge and discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

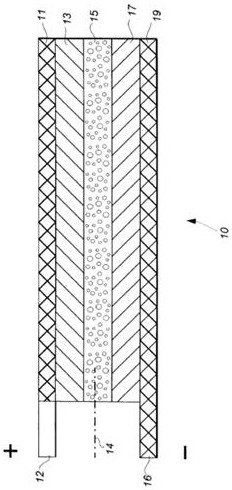

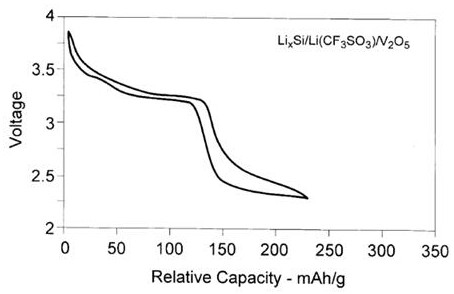

[0031] Make a single-ion lithium embedded sample battery to demonstrate the characteristic parameters such as working voltage and capacity of existing lithium-ion batteries. Positive electrode components include: 28% (diameter 20-60nm) V 2 o 5 , 6% conductive carbon black, 15% PVDF binder, 23% DBP plasticizer and 28% acetone. After the positive electrode component was dried at 22°C for 0.5 hours, a stable film was formed, and then a 1cm area was cut from the film. 2 The circular positive pole piece, and then use ether to extract the plasticizer in the positive pole piece. A typical positive electrode sheet contains 5-20mg of V 2 o 5 active substance.

[0032] The production process of the negative pole piece is similar to that of the positive pole piece, except that silicon powder is used instead of V 2 o 5Lithium-silicon alloy Li is formed by covering the dry and purified silicon powder film on the metal lithium foil. x Si negative electrode sheet, and finally cut the...

Embodiment 2

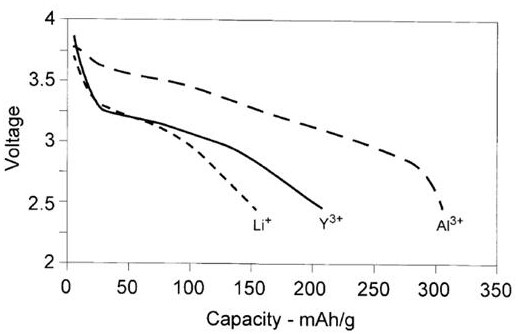

[0035] Using the same manufacturing process as in Example 1, make another dual-ion battery as a comparison group test: the active materials of the positive and negative electrodes are V 2 o 5 and MoS x , the formulation of the electrolyte is 0.5M Y(ClO 4 ) 3 , EC (ethylene carbonate): DMC (dimethyl carbonate) = 2:1. Test the assembled battery according to the same conditions in Example 1 and record the data: as figure 2 Y in 3+ As shown in the first discharge characteristic curve, the first discharge capacity of the battery is increased to 200mAh / g.

Embodiment 3

[0037] Using a similar manufacturing process and active material as in Example 2, the double ion battery in the specific embodiment of the present invention is made: at least one ion in the double ion is Al 3+ . Specifically, although the active materials of the positive and negative electrodes are the same as in Example 1, the active cations in the electrolyte are different: the formula of the electrolyte is 0.5M Al(ClO 4 ) 3 , EC (ethylene carbonate): DMC (dimethyl carbonate) = 2:1. Such as figure 2 Al in 3+ As shown in the first discharge characteristic curve, the first discharge capacity of the battery has been significantly improved, reaching 300mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com