A Dielectric Metal Hybrid 3D Printed Hyperbolic Lens Antenna

A three-dimensional printing, lens antenna technology, applied in the direction of antenna, antenna support/installation device, radiation unit cover, etc., can solve the problems of signal reflection, poor flexibility, affecting lens performance, etc., to eliminate electromagnetic wave reflection, improve reflection coefficient, Highly flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

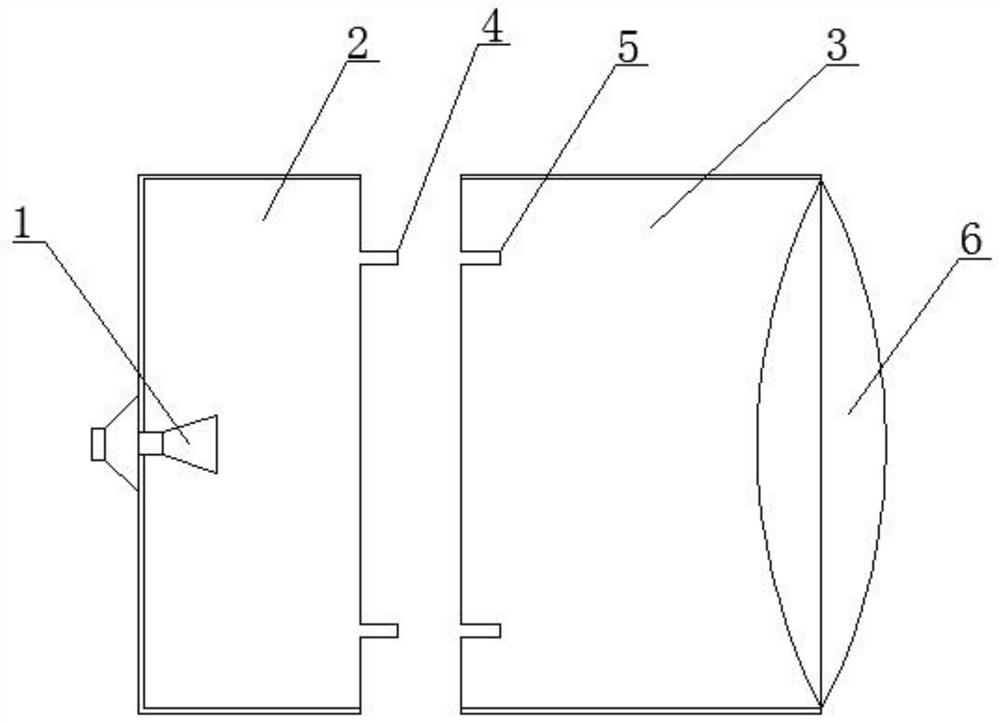

[0015] Such as figure 1 As shown: the present invention includes an antenna, a first housing, a second housing, a housing docking plug, a housing docking jack and a lens, the antenna is fixedly installed in the middle of the first housing, and the first The shell and the second shell are detachably connected by the shell docking plug and the shell docking socket, and the lens is fixedly arranged in the second shell.

[0016] Preferably, the first casing and the second casing are processed by three-dimensional printing.

[0017] Preferably, the first shell and the second shell are made of aluminum, copper, silicon, iron, titanium, chromium, elastic fiber, quartz sand, ABS resin, neoprene rubber, polyisobutylene, ethylene-vinyl acetate copolymer things made.

[0018] By weight, the aluminum accounts for 15%, the copper accounts for 5%, the silicon accounts for 3%, the iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com