Carbon material supported palladium catalyst, as well as preparation and application thereof

A palladium catalyst and carbon material technology, applied in the field of palladium catalysts supported by carbon materials, can solve the problems of catalysts being difficult to reuse, low oxidant contact efficiency, and few reaction sites, and achieve simple and easy preparation methods, low cost, The effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

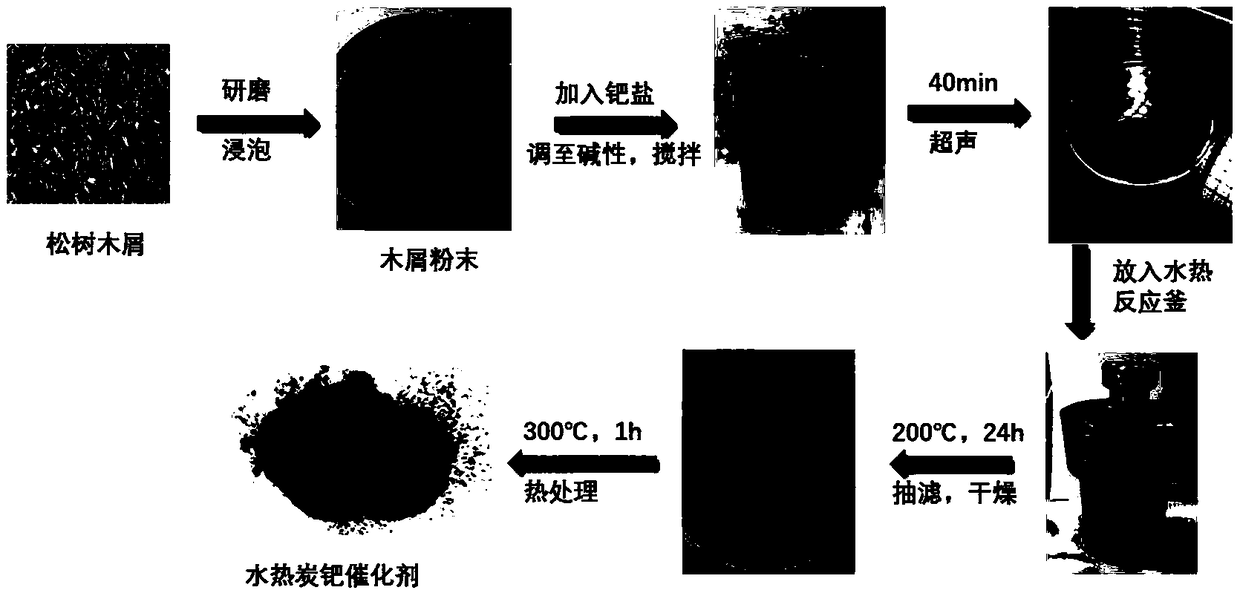

[0033] The preparation method of the palladium catalyst that the carbon material that the present invention proposes immobilizes may further comprise the steps:

[0034] (1) Mix the biomass material and the palladium salt solution, adjust the pH to alkaline, perform a hydrothermal reaction after mixing to obtain a hydrothermal reaction product; the hydrothermal reaction is used to hydrothermally carbonize the biomass material, and Organic functional groups on the surface bind to palladium;

[0035] (2) The hydrothermal reaction product is subjected to solid-liquid separation to obtain a solid phase, and the solid phase is dried and then heat-treated to obtain the carbon-supported palladium catalyst; the heat treatment is used to remove the dried Binding water in the product, increasing the specific surface area of the product and improving the binding force between the carbon substrate and palladium.

[0036] The biomass material in step (1) can be any biomass material, and...

Embodiment 1

[0060] A kind of preparation method of the palladium catalyst that carbon material is immobilized, the preparation process schematic diagram is as figure 1 shown, including the following steps:

[0061] (1) After mixing sawdust and palladium salt, adjust the pH to 10.0, stir with a magnetic stirrer at room temperature for 3 hours, and then put the mixed mixture into an ultrasonic wave for 40 minutes to make the Pd and sawdust evenly dispersed. Put the ultrasonically completed mixture into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 200°C for 24 hours, vacuum filter, and dry to obtain a hydrothermal reaction product; sieve wood chips, select 50-mesh undersize, 200-mesh oversize , that is, the particle size range of wood chips is selected to be 75-280 μm, the mass ratio of palladium salt to wood chips is 1:10, and the solid-liquid ratio of the hydrothermal reaction is 1:10, the catalyst performance is better,

[0062] (2) The hydrothermal reaction product...

Embodiment 2

[0080] A kind of preparation method of the palladium catalyst particle of carbon material immobilization, comprises the steps:

[0081] (1) Use dried corn cobs, after grinding, take the 50-mesh sieve and the 200-mesh sieve (particle size 75-280 μm) and mix them with palladium salt, adjust the pH to 10.0, and stir with a magnetic stirrer at room temperature After 2 hours, put the mixed mixture into an ultrasonic wave for 30 minutes, so that the Pd and biomass materials are evenly dispersed. Put the ultrasonically completed mixture into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 200°C for 12 hours, vacuum filter, and dry to obtain a hydrothermal reaction product; the mass ratio of palladium salt to sawdust is 1:10, and the hydrothermal reaction The solid-liquid ratio of the reaction is 1:5, and the performance of the prepared catalyst is better.

[0082] (2) The hydrothermal reaction product is subjected to solid-liquid separation to obtain a solid phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com