High-temperature resistant radar wave-absorbing material based on double-layer metamaterial and preparation method of high-temperature resistant radar wave-absorbing material

A technology of radar absorbing materials and metamaterials, applied in the field of radar absorbing materials, can solve the problems of high production cost, high process requirements, increased production difficulty, etc., and achieves rigorous mixing ratio, simple and easy-to-obtain raw materials, and wave absorbing ability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

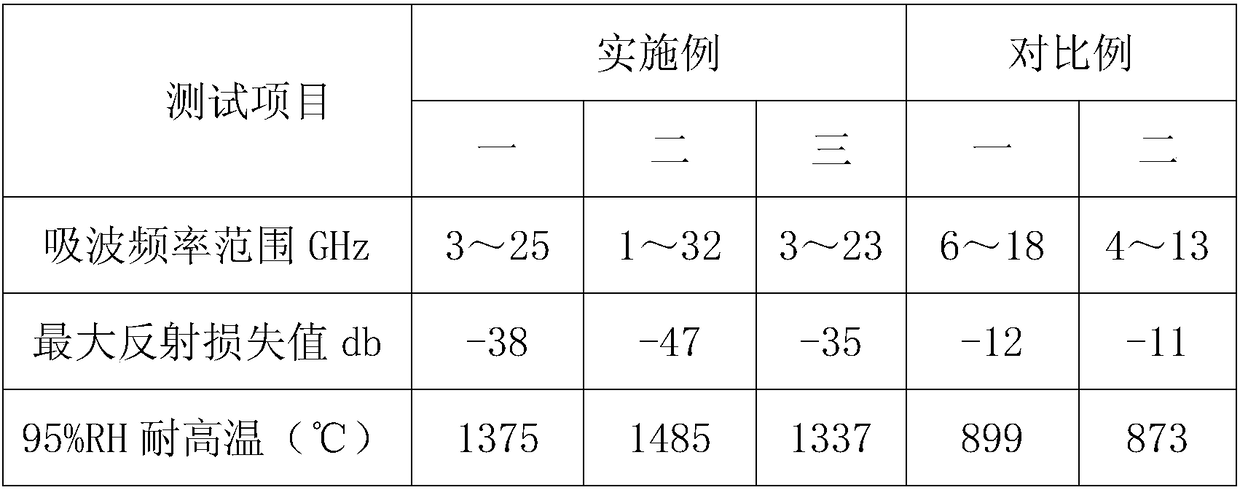

Examples

Embodiment 1

[0019] A high-temperature-resistant radar wave-absorbing material based on double-layer metamaterials proposed by the present invention includes an inner dielectric layer, an inner resistive high-temperature metamaterial layer, an intermediate dielectric layer, and an outer resistive high-temperature metamaterial from the inside to the outside. layer and the outer dielectric layer, the inner resistive high-temperature metamaterial layer includes the following raw materials in parts by weight: 80 parts of polyphenylene sulfide, 20 parts of polytetrafluoroethylene, 3 parts of silicon nitride, and 1.5 parts of ferric oxide , 4 parts of 2-hydroxypropyl acrylate, 2 parts of copper fiber, and 1 part of lubricant; the outer resistive high-temperature metamaterial layer includes the following raw materials in parts by weight: 80 parts of polypyrrole, 20 parts of polytetrafluoroethylene, 1 part of nano-zinc oxide, 2 parts of barium lanthanum hexaboride, 5 parts of dimethylaminoethyl acr...

Embodiment 2

[0026] A high-temperature-resistant radar wave-absorbing material based on double-layer metamaterials proposed by the present invention includes an inner dielectric layer, an inner resistive high-temperature metamaterial layer, an intermediate dielectric layer, and an outer resistive high-temperature metamaterial from the inside to the outside. layer and the outer dielectric layer, the inner resistive high-temperature metamaterial layer includes the following raw materials in parts by weight: 100 parts of polyphenylene sulfide, 25 parts of polytetrafluoroethylene, 4.5 parts of silicon nitride, and 1.5 parts of ferric oxide , 8 parts of 2-hydroxypropyl acrylate, 4 parts of copper fiber, and 1.5 parts of lubricant; the outer resistance type high-temperature metamaterial layer includes the following raw materials in parts by weight: 100 parts of polypyrrole, 25 parts of polytetrafluoroethylene, 2.5 parts of nano-zinc oxide, 2.5 parts of barium lanthanum hexaboride, 8 parts of dime...

Embodiment 3

[0033]A high-temperature-resistant radar wave-absorbing material based on double-layer metamaterials proposed by the present invention includes an inner dielectric layer, an inner resistive high-temperature metamaterial layer, an intermediate dielectric layer, and an outer resistive high-temperature metamaterial from the inside to the outside. layer and the outer dielectric layer, the inner resistive high-temperature metamaterial layer includes the following raw materials in parts by weight: 120 parts of polyphenylene sulfide, 30 parts of polytetrafluoroethylene, 8 parts of silicon nitride, and 2 parts of ferric iron tetroxide , 12 parts of 2-hydroxypropyl acrylate, 6 parts of copper fiber, and 2 parts of lubricant; the outer resistance type high-temperature metamaterial layer includes the following raw materials in parts by weight: 120 parts of polypyrrole, 30 parts of polytetrafluoroethylene, 8 parts of nano-zinc oxide, 4 parts of barium lanthanum hexaboride, 12 parts of dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com