A system and method for preparing phosphoric acid and silicon-calcium-potassium-magnesium fertilizer from phosphate rock

A silicon-calcium-potassium-magnesium and phosphoric acid technology, applied in chemical instruments and methods, phosphoric acid, phosphate fertilizers, etc., can solve the problems of harmful solid waste generation, complex preparation process, low utilization rate of hydrochloric acid, etc., and achieve good conditioning effect and loss of fertilizer efficiency Less, realize the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

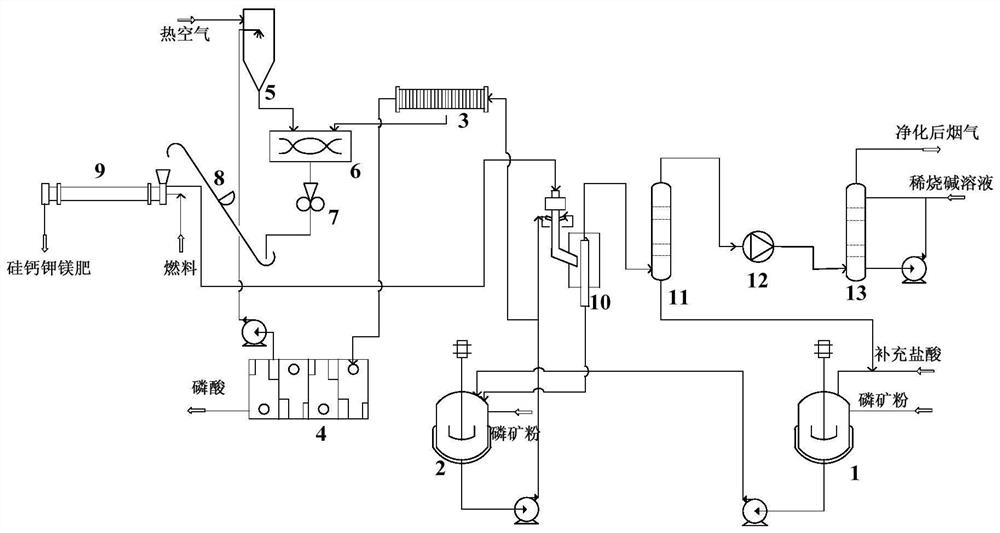

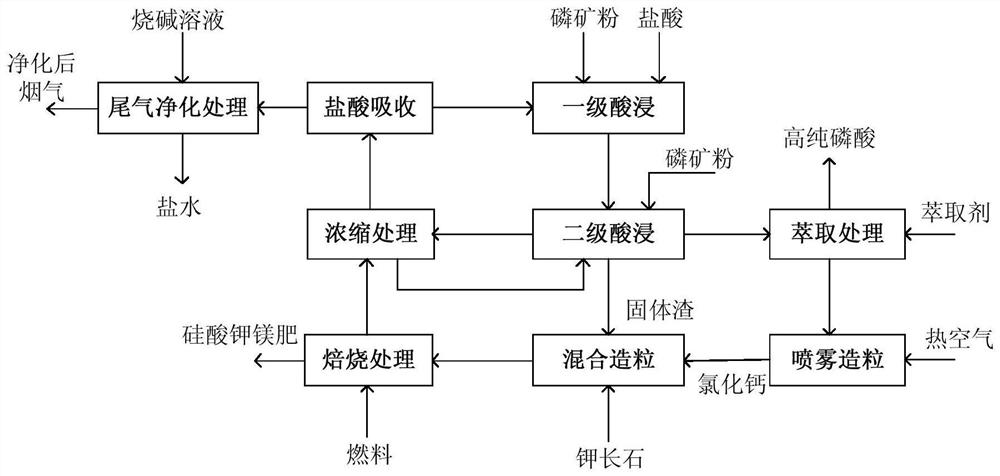

[0089] This embodiment provides a system for preparing phosphoric acid and silicon-calcium-potassium-magnesium fertilizer from phosphate rock, and the device connection schematic diagram of the system is as follows figure 1 As shown, it includes acid leaching unit, solid-liquid separation device 3, extraction device 4, granulation unit, roasting device 9, hydrochloric acid absorption unit and tail gas purification device 13;

[0090]The liquid outlet of the acid leaching unit is connected with the liquid inlet of the solid-liquid separation device 3 and the hydrochloric acid absorption unit respectively, the liquid outlet of the solid-liquid separation device 3 is connected with the liquid inlet of the extraction device 4, and the extraction of the extraction device 4 Phosphoric acid is obtained from the liquid outlet, and the raffinate outlet of the extraction device 4 and the solid outlet of the solid-liquid separation device 3 are all connected to the granulation unit, and t...

Embodiment 2

[0099] This embodiment provides a system for preparing phosphoric acid and silicon-calcium-potassium-magnesium fertilizers from phosphate rock. The system refers to Example 1, the only difference is that the acid leaching unit only includes a primary acid leaching tank 1, and the one The liquid outlet of the first-stage acid leaching kettle 1 is connected with the liquid inlet of the solid-liquid separation device 3 and the hydrochloric acid absorption unit respectively, and the liquid outlet of the said concentration device 10 and the liquid outlet of the hydrochloric acid absorption tower 11 are all connected with the liquid of the first-level acid leaching kettle 1. The entrance is connected.

[0100] In this embodiment, the process operation of the system is basically the same as in Example 1, wherein only one acid leaching tank is used, and the time required for the acid leaching reaction to reach the same conversion rate is prolonged, which affects the continuity of the a...

Embodiment 3

[0102] This embodiment provides a system for preparing phosphoric acid and silicon-calcium-potassium-magnesium fertilizers from phosphate rock. The system refers to Example 1, the only difference being that the hydrochloric acid absorption unit does not include a concentration device 10, and the secondary acid leaching The liquid outlet of the kettle 2 is only connected with the solid-liquid separation device 3, and the gas outlet of the roasting device 9 is directly connected with the gas inlet of the hydrochloric acid absorption tower 11.

[0103] In the present embodiment, the technological operation process of the system is basically the same as that of Embodiment 1, but since the concentrating device 10 is not provided, that is, the reaction slurry is not concentrated with the flue gas generated by roasting, the time required for the phosphate rock powder to reach the same conversion rate Extended, the HCl in the flue gas basically needs to be absorbed by the hydrochloric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com