A shock-absorbing, wear-resistant and antibacterial rubber floor mat and its preparation method

A floor mat and rubber technology, which is applied to carpets, etc., can solve the problems of general anti-shock and anti-collision effect, easy to be affected by moisture and breed bacteria, and high resource consumption, so as to achieve the goal of not easy to discoloration, deformation and warping, good shock absorption effect, and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned shock-absorbing, wear-resistant and antibacterial rubber floor mat comprises the following steps:

[0039] 1) Production of the bottom layer: Mix the waste rubber particles and adhesive evenly, pour it into a mold, and shape it under the conditions of a pressure of 7-8MPa and a temperature of 160-180°C to obtain the bottom layer;

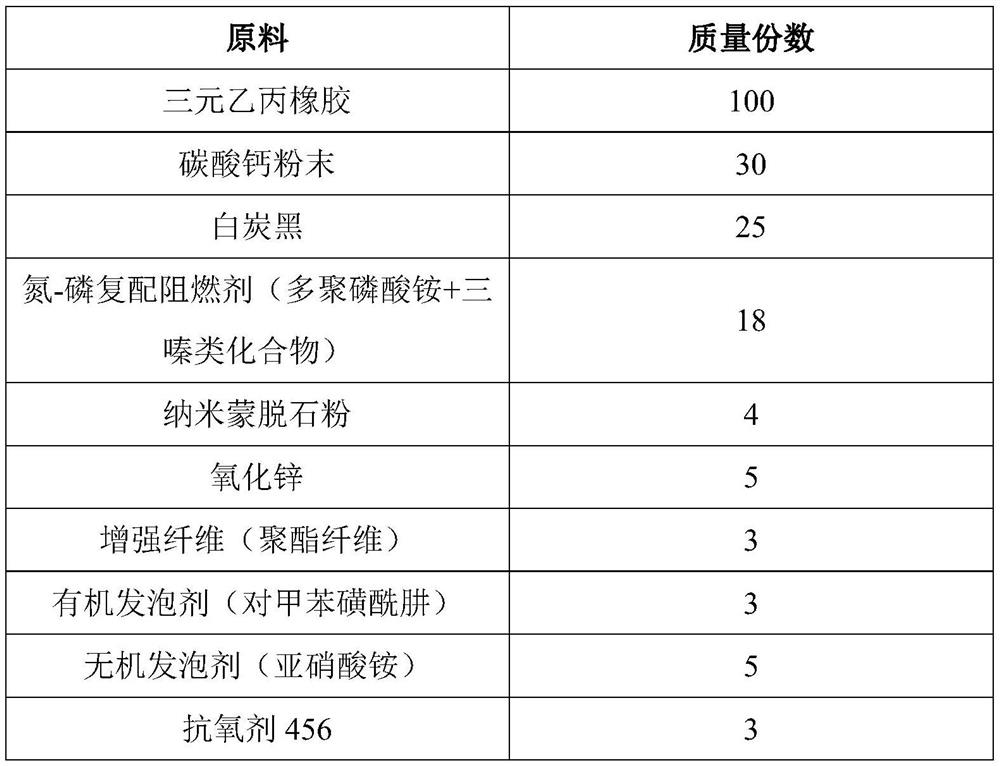

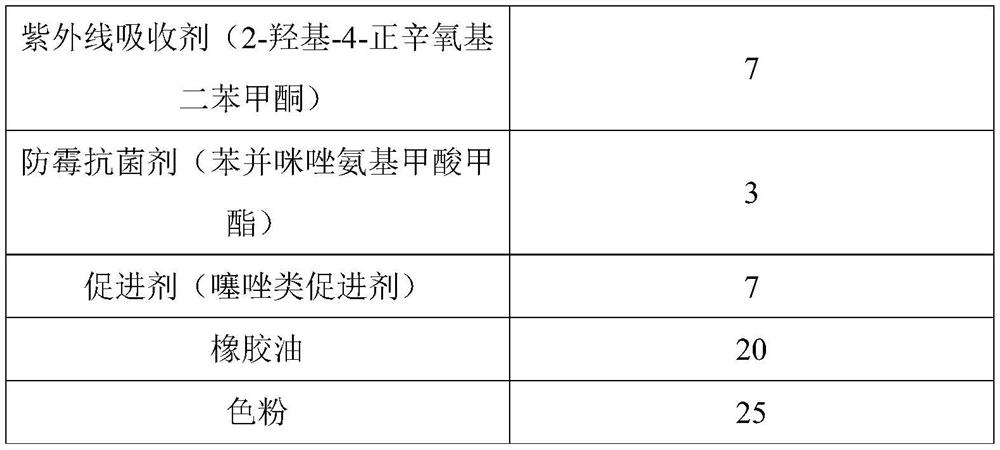

[0040] 2) The production of the surface layer: EPDM rubber, calcium carbonate powder, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, reinforcing fiber, antioxidant, ultraviolet absorber, Add antifungal and antibacterial agent, accelerator, rubber oil and toner to the internal mixer, mix at a temperature of 140-160°C, then transfer the material to a flat vulcanizer, and add organic foaming agent and inorganic foaming agent agent, under the condition of pressure 8-15MPa and temperature 160-180℃, carry out press vulcanization, and then relea...

Embodiment 1

[0047] The preparation method of a shock-absorbing, wear-resistant and antibacterial rubber floor mat is as follows:

[0048] 1) Production of the bottom layer: Mix waste rubber particles (particle size 2-3mm) and adhesive evenly according to the mass ratio of 8:1, pour it into a mold, and shape it under the conditions of a pressure of 7MPa and a temperature of 170°C to obtain a bottom layer (thickness of 5mm);

[0049]2) The production of the surface layer: EPDM rubber, calcium carbonate powder, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, reinforcing fiber, antioxidant, ultraviolet absorber, Antifungal and antibacterial agents, accelerators, rubber oil and toner are added to the internal mixer, mixed at a temperature of 140°C, and then the materials are transferred to a flat vulcanizer, and organic foaming agents and inorganic foaming agents are added. Under the conditions of pressure 10MPa and temperature 160°C,...

Embodiment 2

[0056] The preparation method of a shock-absorbing, wear-resistant and antibacterial rubber floor mat is as follows:

[0057] 1) Production of the bottom layer: mix waste rubber particles (particle size 3-4 mm) and adhesive evenly according to the mass ratio of 8:1, pour it into a mold, and shape it under the conditions of a pressure of 7 MPa and a temperature of 180 ° C to obtain a bottom layer (thickness of 7mm);

[0058] 2) The production of the surface layer: EPDM rubber, calcium carbonate powder, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, reinforcing fiber, antioxidant, ultraviolet absorber, Antifungal and antibacterial agents, accelerators, rubber oil and toner are added to the internal mixer, mixed at a temperature of 140°C, and then the materials are transferred to a flat vulcanizer, and organic foaming agents and inorganic foaming agents are added. Under the conditions of pressure 8MPa and temperature 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com