Nanoparticle enhanced type hydrogel as well as preparation method and application thereof

A nanoparticle-enhanced technology, which is applied in the field of nanoparticle-enhanced hydrogel and its preparation, can solve problems such as excessive degradation speed and insufficient mechanical strength, and achieve great promotion and use value, low cost, and expanded application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

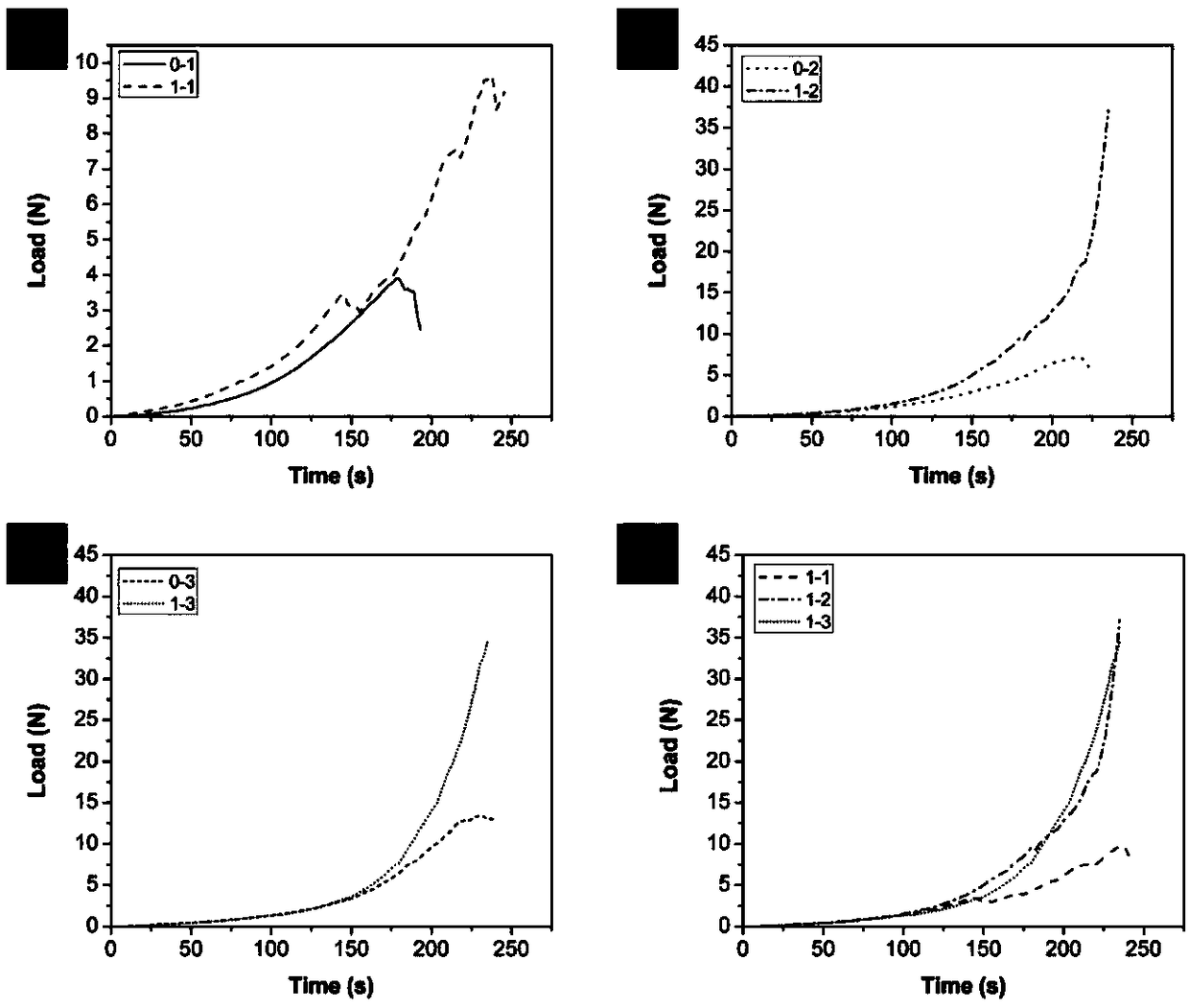

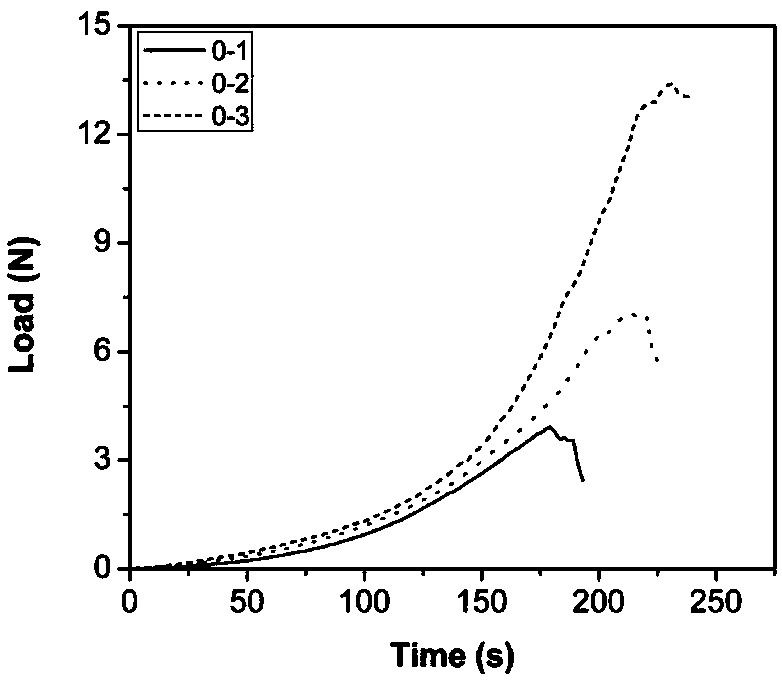

[0028] Dissolve 120mg of sodium alginate powder in 6ml of deionized water, stir with a magnetic stirrer until it is completely dissolved, then suspend the P-S nanoparticles in the sodium alginate solution at 5% of the mass of sodium alginate; stir evenly, and remove it from the solution by ultrasonication for 30s The small air bubbles were added to the 24-well cell culture plate according to the volume of 2ml per well.

[0029] According to Ca 2+ Molar ratios to -COOH f=0.27, 0.36, 0.54 Weigh 9.4mg, 12.4mg, 18.6mg of graphene oxide powder respectively, suspend each in 0.5ml deionized water, and then add it into the sodium alginate solution in the orifice plate , Blow evenly with the tip of a pipette, and the solution is white turbid and milky at this time.

[0030] Weigh 23.2mg, 30.6mg, and 46.4mg of gluconolactone according to different f values, respectively dissolve them in 200ul deionized water, add them to the corresponding solutions containing sodium alginate and graphe...

Embodiment 2

[0032] Dissolve 120mg of sodium alginate powder in 6ml of deionized water to obtain a 2% sodium alginate solution, stir with a magnetic stirrer until completely dissolved; then suspend the P-S nanoparticles in the sodium alginate solution according to 5% of the mass of sodium alginate In the solution, stir evenly, sonicate for 30s to remove small air bubbles in the solution, and then add it into a 24-well cell culture plate according to the volume of 4ml per well.

[0033] According to Ca 2+ The molar ratio to -COOH f=0.54 Weigh 18.6mg of graphene oxide powder, suspend each in 0.5ml of deionized water, then add it to the sodium alginate solution in the orifice plate, and blow it evenly with the tip of a pipette. At this time, the solution is White cloudy milky.

[0034] Weigh 92.8 mg of gluconolactone, dissolve it in 200ul of deionized water, then add it into the solution containing sodium alginate and graphene oxide, and stir slightly with a pipette tip to make the GDL solut...

Embodiment 3

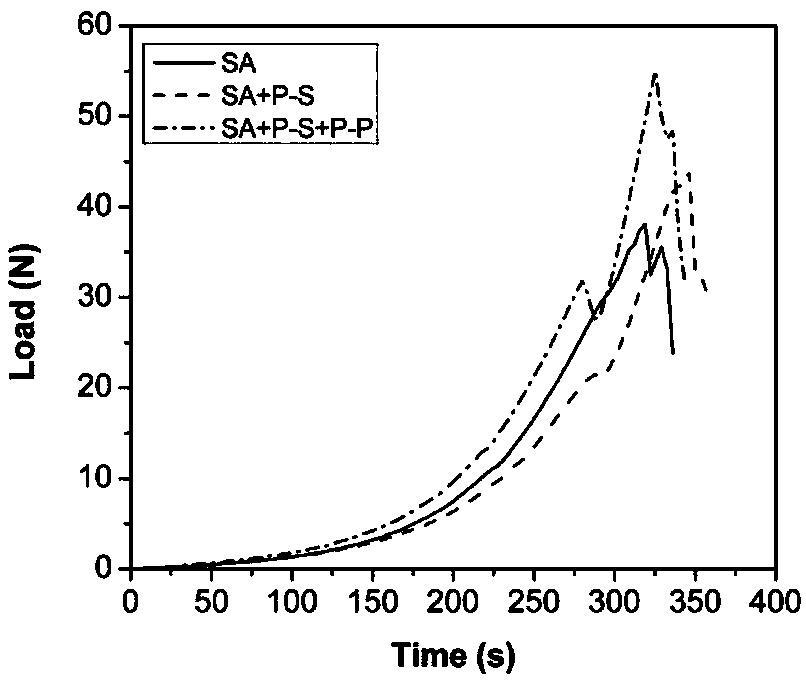

[0036] Dissolve 120mg of sodium alginate powder in 6ml of deionized water to obtain a 2% sodium alginate solution, stir with a magnetic stirrer until completely dissolved; then mix equal amounts of P-S and P-P nanoparticles according to 5% of the mass of sodium alginate Suspended in sodium alginate solution, stirred evenly, ultrasonicated for 30s to remove small air bubbles in the solution, and then added to a 24-well cell culture plate at a volume of 4ml per well.

[0037] According to Ca 2+ The molar ratio to -COOH f=0.54 Weigh 18.6mg of graphene oxide powder, suspend each in 0.5ml of deionized water, then add it to the sodium alginate solution in the orifice plate, and blow it evenly with the tip of a pipette. At this time, the solution is White cloudy milky.

[0038] Weigh 92.8 mg of gluconolactone, dissolve it in 200ul of deionized water, then add it into the solution containing sodium alginate and graphene oxide, and stir slightly with a pipette tip to make the GDL solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com