Recombinant proteus pseudomonadaceae for producing L-xylose and application thereof

A technology of Pseudomonas mutans and recombinant bacteria, applied in the field of bioengineering, can solve the problems of many chemical procedures, many impurities in sugar solution, affecting the extraction process and product quality, and achieve the effect of simple process operation and good fermentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Construction and identification of recombinant plasmid pME6032-2gadh

[0040] Obtain sequences such as SEQ ID NO.1, SEQ ID NO.2, and SEQ ID NO.3 by chemical synthesis, design primers (2GADH-1, 2GADH-2, 2GADH-3, see Table 1), combine the above 2 The genes of the three subunits of the -ketogluconate dehydrogenase gene (2GADH) were ligated at pME6032 plasmid overnight at 16°C with restriction sites EcoRI, SacI, KpnI, and NcoI, and the ligation product pME6032-gadh was chemically transformed into the large intestine Bacillus JM109 competent cells. Spread the transformation solution on an LB plate containing 50 mg / L tetracycline, extract the plasmid and sequence to verify the constructed recombinant plasmid.

[0041](2) Construction of recombinant strain P.plecoglossicida-2gadh

[0042] The plasmid pME6032-2gadh constructed in (1) was transformed into the starting strain Pseudomonas.plecoglossicida CGMCC 7150 by electroporation, and the positive strain P.plecoglossicid...

Embodiment 2

[0048] The starting strain was Pseudomonas plecoglossicida CGMCC 1.12685, and the rest of the steps were the same as in Example 1, and the positive recombinant strain P.plecoglossicida1-2gadh-25dkg-pdc was screened.

Embodiment 3

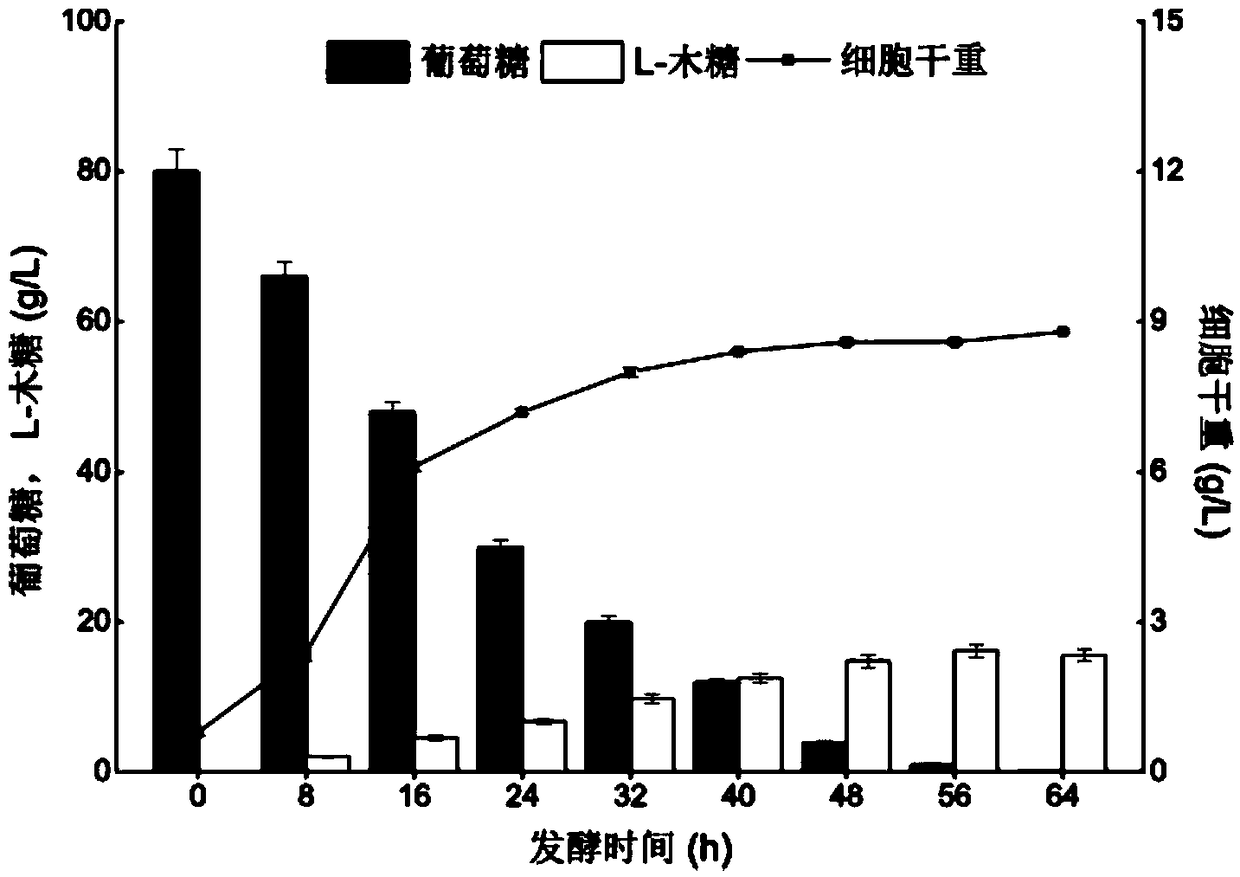

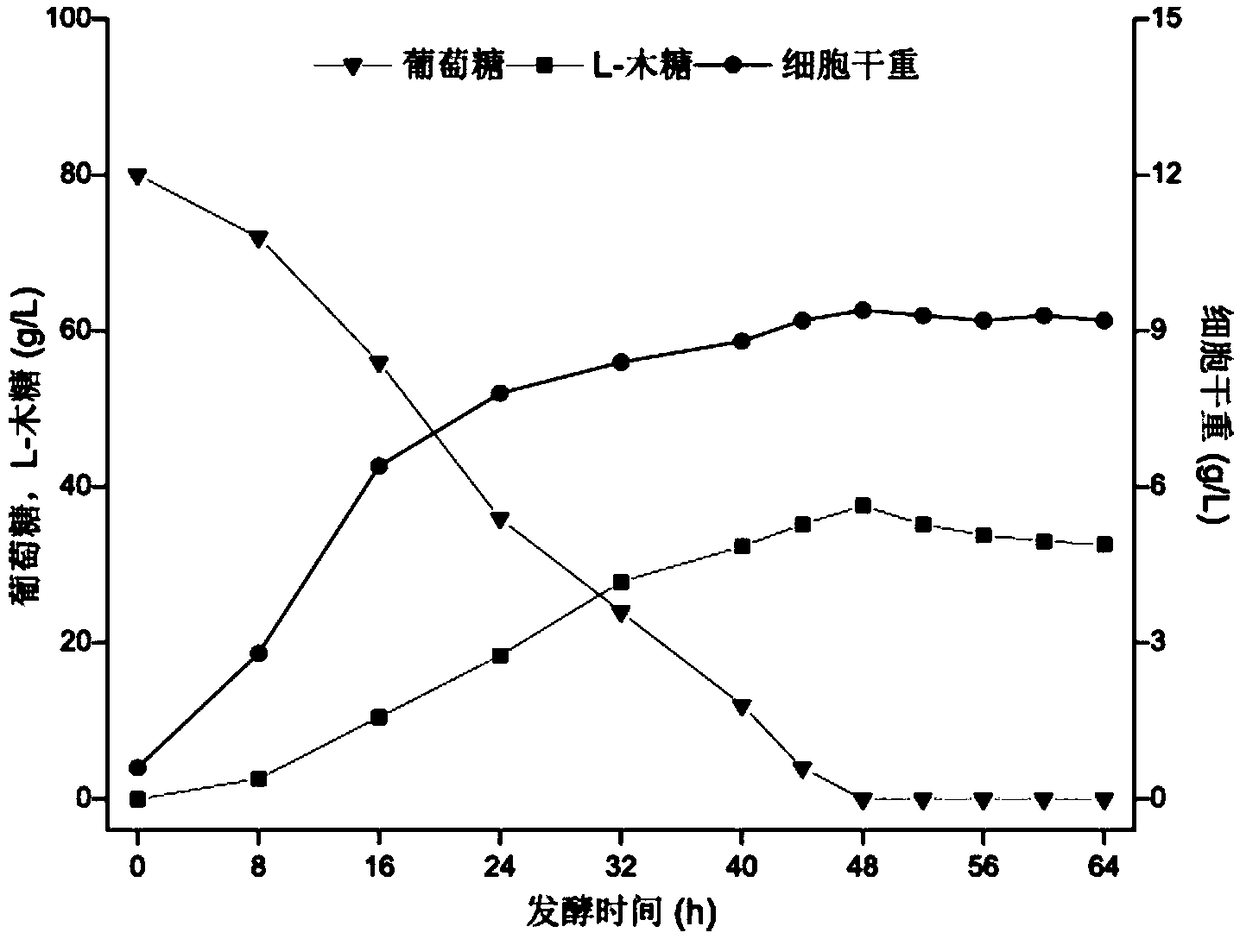

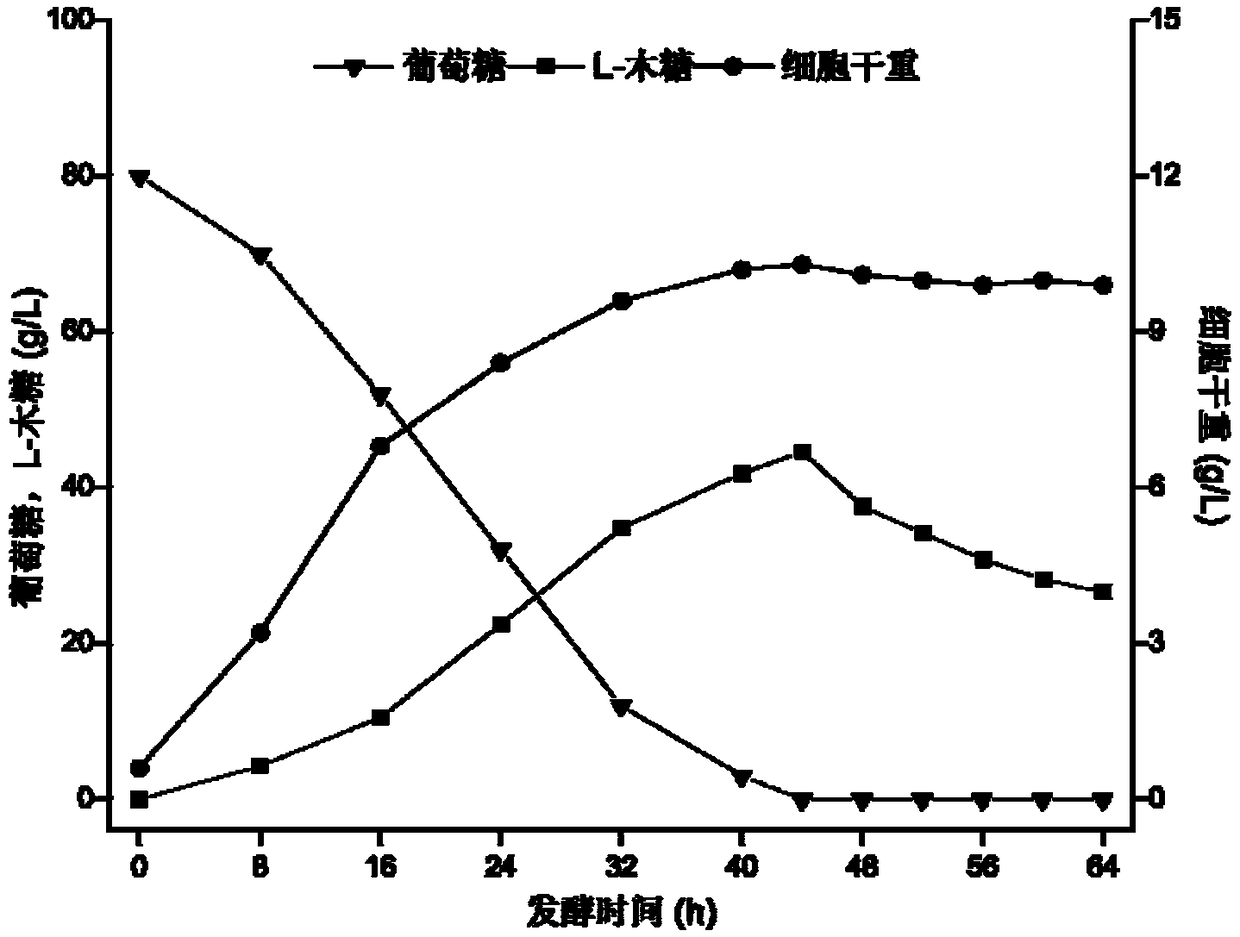

[0049] Example 3 Cultivation of recombinant strain P.plecoglossicida-2gadh-25dkg-pdc and L-xylose fermentation

[0050] Seed medium: glucose 15.0g / L, corn steep liquor 4.0g / L, urea 2.0g / L, KH 2 PO 4 2.0g / L, MgS04 7H 2 O 0.5g / L, CaCO 3 1.0g / L, pH 7.0.

[0051] Fermentation medium: glucose 80.0g / L, corn steep liquor 4.0g / L, urea 2.0g / L, KH 2 PO 4 2.0g / L, MgSO 4 ·7H 2 O 0.5g / L, CaCO 3 10.0g / L, pH 6.8.

[0052] Shake flask culture: get appropriate bacterium (gained in embodiment 1) suspension and inoculate in the 500ml shake flask that 50ml seed culture medium is housed, at 30 ℃, cultivate 16-20h under the condition of 220r / min, with 10% inoculum size Transfer to a 500ml shake flask with 50ml of fermentation medium, cultivate to OD at 30°C and 220r / min 650 When it is 0.6, use IPTG to induce, and the final concentration is 0.5mM. The induction temperature is 25°C, fermented for 64 hours, and samples are taken regularly.

[0053] Determination of the output of L-xylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com