Preparation method of PCL heterogeneous induced shish-kebab fiber

A fiber and heterogeneous technology, which is applied in the field of preparation of PCL heterogeneously induced skimmer fibers, can solve rare problems and achieve the effects of stable performance, cost reduction and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

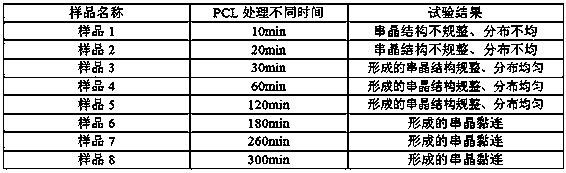

Embodiment 1

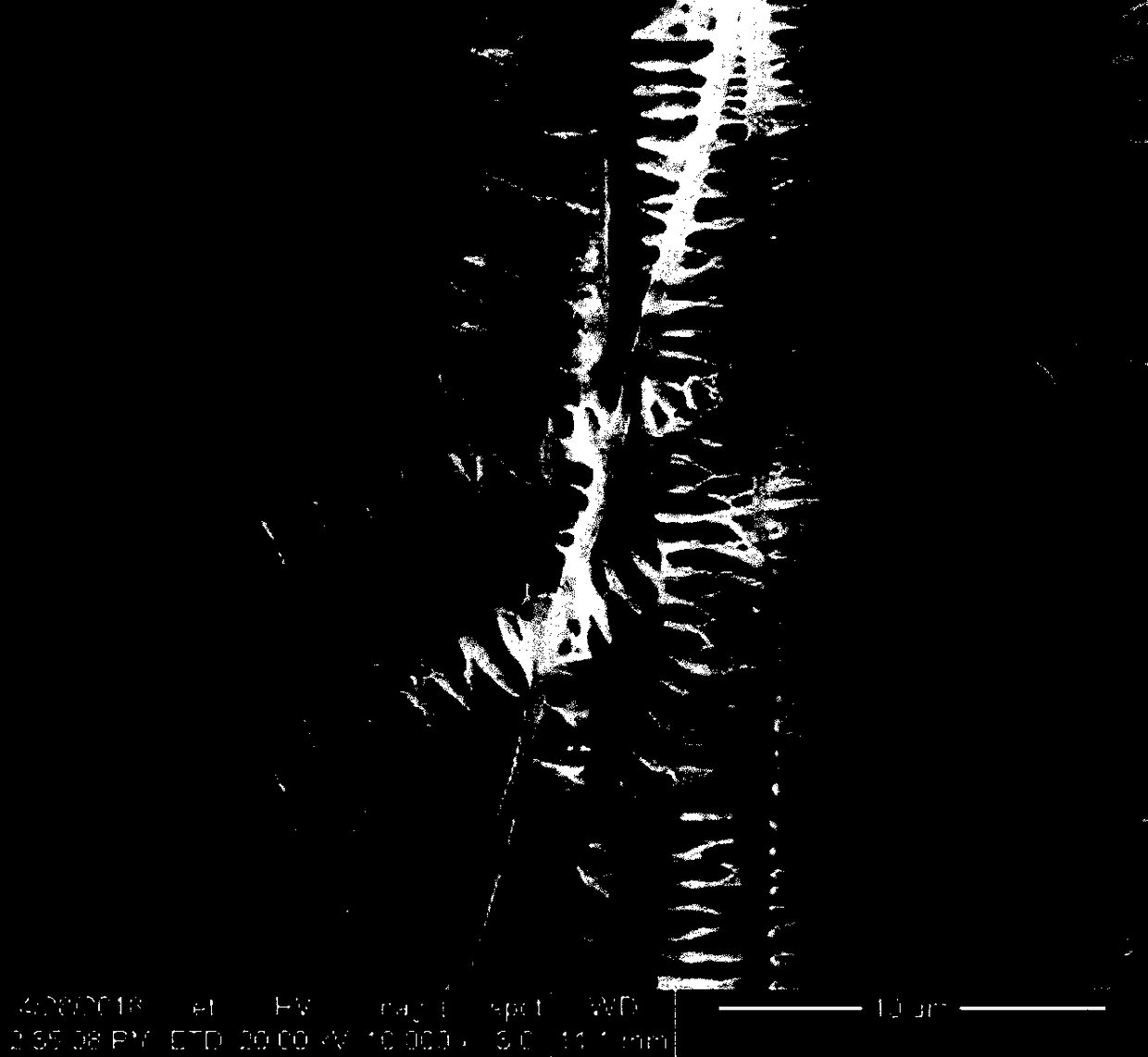

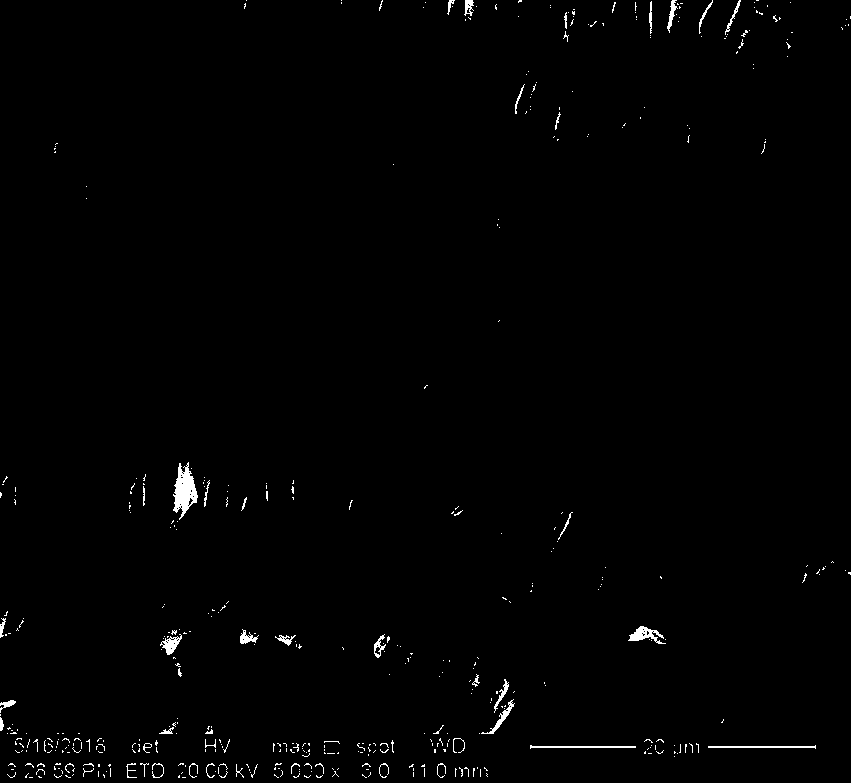

[0029] A preparation method of PCL heterogeneous induced skewered fiber, comprising the following steps:

[0030] (1) Dissolve 1.39g of PLA with a molecular weight of 50,000 into 15.96g of hexafluoroisopropanol, mix well, make a spinning solution and perform electrospinning to obtain a PLA fiber membrane.

[0031] (2) Alkali treatment of PLA fibers: soak the PLA fiber membrane prepared in step (1) in 2wt% sodium hydroxide aqueous solution for 10 minutes, then add 4wt% acetic acid aqueous solution to adjust the pH value to Neutral, wash, dry.

[0032] (3) Add 2g of PCL with a molecular weight of 50,000 to 98g of acetic acid aqueous solution with a mass concentration of 50wt%, and mix well to obtain a PCL solution with a concentration of 2wt% for later use; at 20°C, place the PLA fiber after alkali treatment Soak in PCL solution for 30 minutes, take it out, wash it with 50wt% acetic acid aqueous solution for 3 times, and dry it in vacuum to get the product PCL heterogeneous ind...

Embodiment 2

[0035] A preparation method of PCL heterogeneous induced skewered fiber, comprising the following steps:

[0036] (1) Dissolve 1.39g of PLA with a molecular weight of 80,000 into 15.96g of dichloromethane / N-N-dimethylamide mixed solvent (volume ratio 7:3), mix well, make spinning solution and perform electrospinning, Obtain PLA fiber membrane.

[0037] (2) Alkali treatment of PLA fiber: soak the PLA fiber membrane prepared in step (1) in a 10wt% sodium bicarbonate aqueous solution for 10 minutes, then add 4wt% acetic acid aqueous solution to adjust the pH value to Neutral, wash, dry.

[0038] (3) Add 5g of PCL with a molecular weight of 80,000 to 45g of amyl acetate, mix well to obtain a PCL solution with a concentration of 10wt%, and set aside; at 20°C, soak the PLA fiber after alkali treatment in the PCL solution After 60 minutes, take it out and wash it with amyl acetate for 4 times, and dry it in vacuum to obtain the product PCL heterogeneous induced skew crystal fiber. ...

Embodiment 3

[0041] A preparation method of PCL heterogeneous induced skewered fiber, comprising the following steps:

[0042] (1) Dissolve 2.18g of PLA with a molecular weight of 60,000 into 15.96g of hexafluoroisopropanol, mix well, make a spinning solution and perform electrospinning to obtain a PLA fiber membrane.

[0043] (2) Alkali treatment of PLA fibers: soak the PLA fiber membrane prepared in step (1) in an aqueous sodium carbonate solution with a concentration of 2wt% for 20 minutes, and then add a solution of sodium dihydrogen phosphate with a concentration of 20wt% to adjust the pH value To neutral, wash with water, dry.

[0044] (3) Add 2g of PCL with a molecular weight of 60,000 to 180g of acetic acid / amyl acetate, mix well to obtain a PCL solution with a concentration of 1wt%, and set aside; at 20°C, place the alkali-treated PLA fibers in the PCL solution Immerse in the medium for 180min, take it out, wash it with acetic acid / amyl acetate for 5 times, and dry it in vacuum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com