An ultraviolet positive photoresist

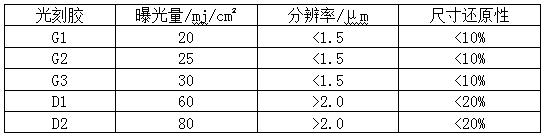

A positive photoresist, ultraviolet technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problem of not meeting the needs of production, and achieve the effect of good size reduction, high photosensitivity, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

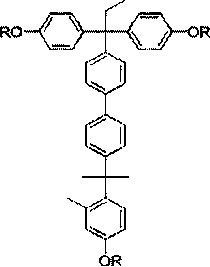

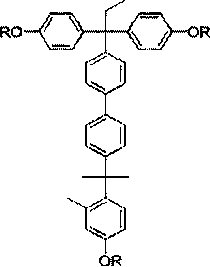

Method used

Image

Examples

Embodiment 1

[0022] Calculated by mass percentage, take 1.5% of diazonaphthoquinone sulfonate photosensitizer with special structure prepared by the above method, 4% of tert-butyl-phenolic resin, 10% of p-methyl-phenolic resin, benzophenone 0.5%, 0.2% carboxylated nitrile rubber, 0.5% hexamethyldisilazane, 0.5% BYK-300 leveling agent and the balance ethyl acetate were mixed evenly to obtain the UV positive photoresist G1 of the present invention.

Embodiment 2

[0024] Calculated by mass percentage, take 2% of diazonaphthoquinone sulfonate photosensitizer with special structure prepared by the above method, 8% of tert-butyl-phenolic resin, 15% of o-methyl-phenolic resin, 4-hydroxy di 0.3% of benzophenone, 0.3% of polyethersulfone, 0.6% of vinyltriethoxysilane, 0.8% of BYK-325 leveling agent and the balance of cyclohexanone are uniformly mixed to obtain the ultraviolet positive photoresist G2 of the present invention .

Embodiment 3

[0026] Calculated by mass percentage, take 3.5% of diazonaphthoquinone sulfonate photosensitizer with special structure prepared by the above method, 20% of m-methyl-phenolic resin, 20% of o-methyl-phenolic resin, benzoin dimethyl ether 0.35%, 0.5% of polyphenylene ether ketone, 0.8% of γ-aminopropyltriethoxysilane, 0.8% of BYK-330 leveling agent and the balance of dimethylacetamide are mixed evenly to obtain the ultraviolet positive light of the present invention Resist G3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com