A kind of b1 level high flame retardant green environmental protection low-voltage AC cable for smart grid and its manufacturing process

A technology of green environmental protection and smart grid, which is applied in the direction of cable/conductor manufacturing, insulated cables, conductor/cable insulation, etc., and can solve the problems that cannot meet the requirements of the B1 combustion level of the user unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

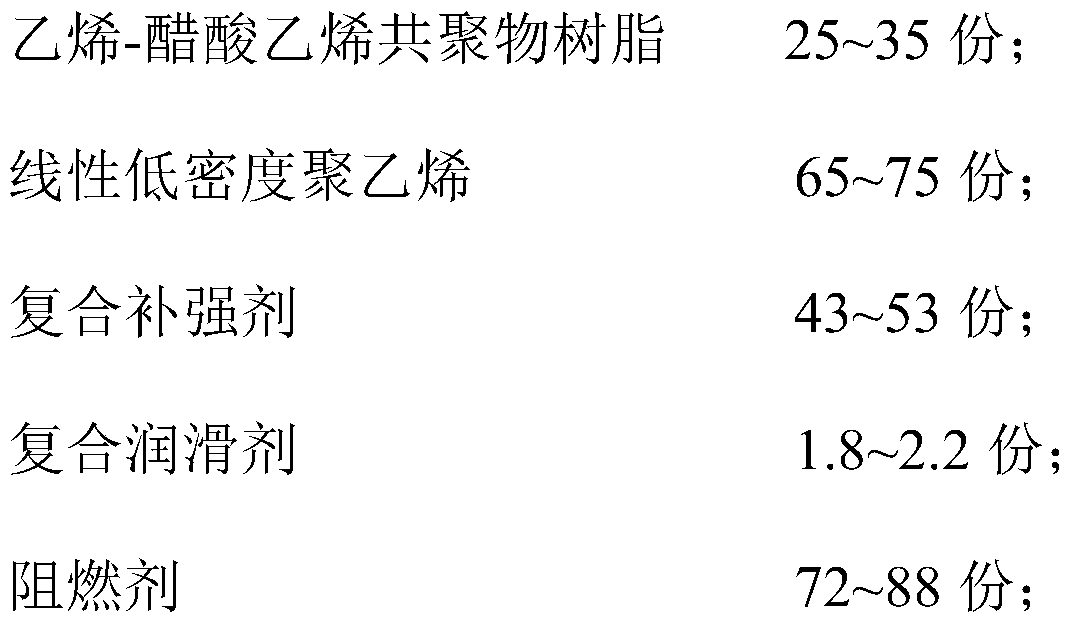

[0066] Mix the following raw materials: ethylene-vinyl acetate copolymer resin 25kg, linear low density polyethylene 75kg, composite reinforcing agent 43kg (diatomaceous earth 15kg, carbon black 28kg), composite lubricant 2.2kg (zinc stearate 1kg, Hydroxy silicone oil 1.2kg), flame retardant 72kg (aluminum hydroxide 72kg), antioxidant 0.9kg (antioxidant 264 0.9kg), ultraviolet absorber 0.55kg (2-hydroxyl-4-n-octyloxydiphenylmethylbenzene ketone 0.55kg), mixed in a high mixer for 2 to 8 minutes, and then transferred to a twin-screw extruder for extrusion at a temperature of 110°C and a screw speed of 60 to 300 rpm, and then granulated at 130°C. Get the outer sheath material and spare it.

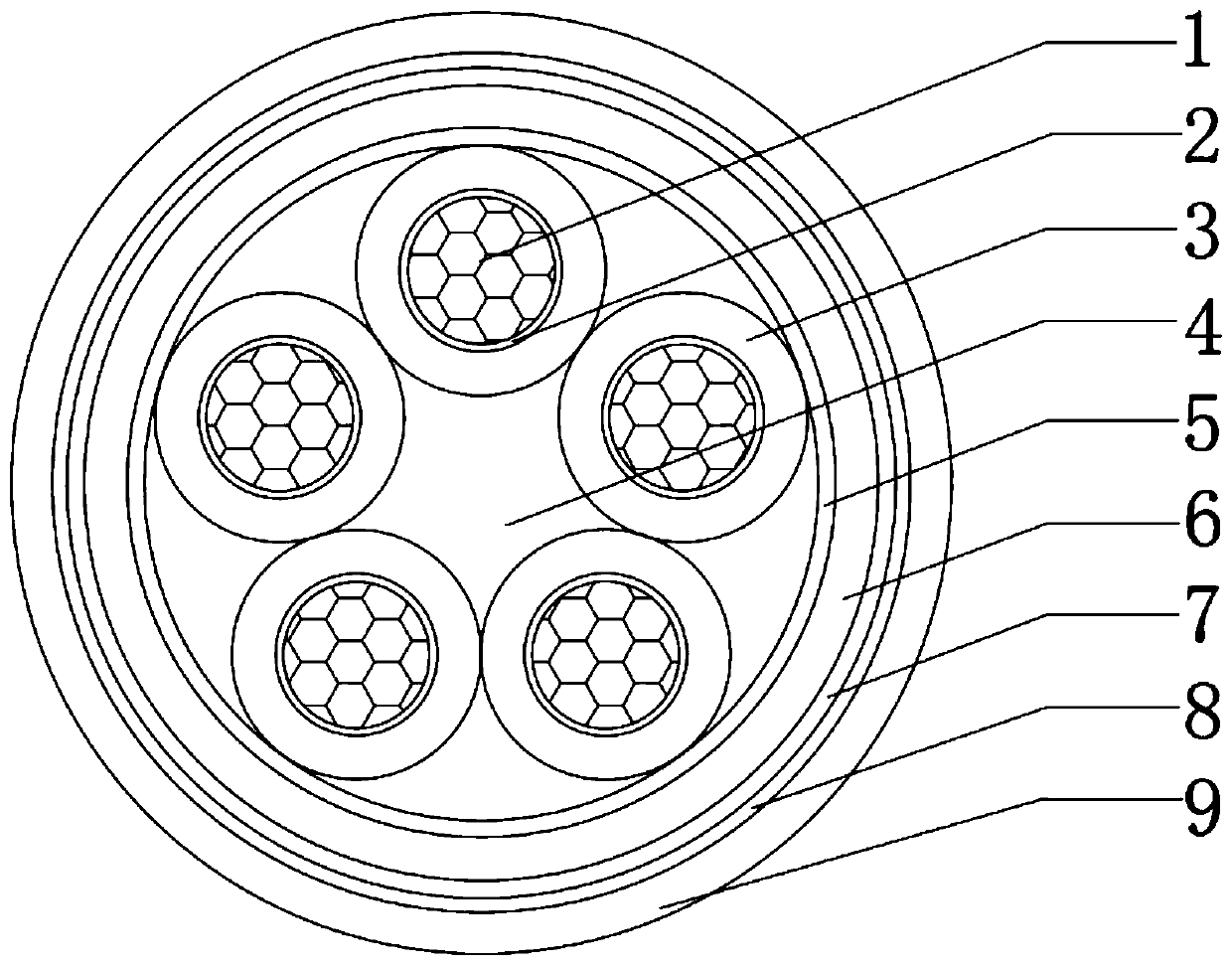

[0067] The 5-conductor core is drawn and annealed, twisted and pressed tightly, and 2 layers of fluorophlogopite tape are overlapped and wrapped around the conductor to form a fire-resistant wrapping layer, and then cross-linked polyethylene is extruded to form an insulating layer and cabled,...

Embodiment 2

[0069] Mix the raw materials of the following weight: 35kg of ethylene-vinyl acetate copolymer resin, 65kg of linear low-density polyethylene, 53kg of composite reinforcing agent (21.2kg of diatomaceous earth, 31.8kg of white carbon black), 1.8kg of composite lubricant (stearic acid Zinc 1kg, hydroxyl silicone oil 0.8kg), flame retardant 88kg (aluminum hydroxide 35kg, magnesium hydroxide 53kg), antioxidant 1.1kg (antioxidant 1076 1.1kg), ultraviolet absorber 0.45kg (2-hydroxy-4 -Methoxybenzophenone 0.25kg, 2-hydroxyl-4-n-octyloxybenzophenone 0.2kg), high mixer mixing for 2 to 8 minutes, then transferred to twin-screw extruder for extrusion , the temperature is 170°C, the screw speed is 60-600 rpm, and then granulated at 120°C to obtain the outer sheath material and set aside.

[0070] The 5-conductor core is drawn and annealed, twisted and pressed tightly, and 3 layers of fluorophlogopite tape are overlapped and wrapped around the conductor to form a fire-resistant wrapping la...

Embodiment 3

[0072] Mix the raw materials of the following weight: ethylene-vinyl acetate copolymer resin 30kg, linear low density polyethylene 70kg, composite reinforcing agent 48kg (diatomaceous earth 18kg, acetylene carbon black 30kg), composite lubricant 2kg (zinc stearate 1kg, Hydroxy silicone oil 1kg), flame retardant 80kg (aluminum hydroxide 42kg, magnesium hydroxide 46kg), antioxidant 1kg (antioxidant 1010 1kg), ultraviolet absorber 0.5kg (2-hydroxy-4-methoxydiphenyl Methanone 0.5kg), mixed in a high mixer for 2-8 minutes, then transferred to a twin-screw extruder for extrusion, the temperature is 150°C, the screw speed is 100-400 rpm, and then pelletized at 140°C That is, the outer sheath material is obtained and set aside.

[0073]The 5-conductor core is drawn and annealed, twisted and pressed tightly, and 2 layers of fluorophlogopite tape are overlapped and wrapped around the conductor to form a fire-resistant wrapping layer, and then cross-linked polyethylene is extruded to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com