A preparation method of a metal-organic frame carbon nanotube composite material

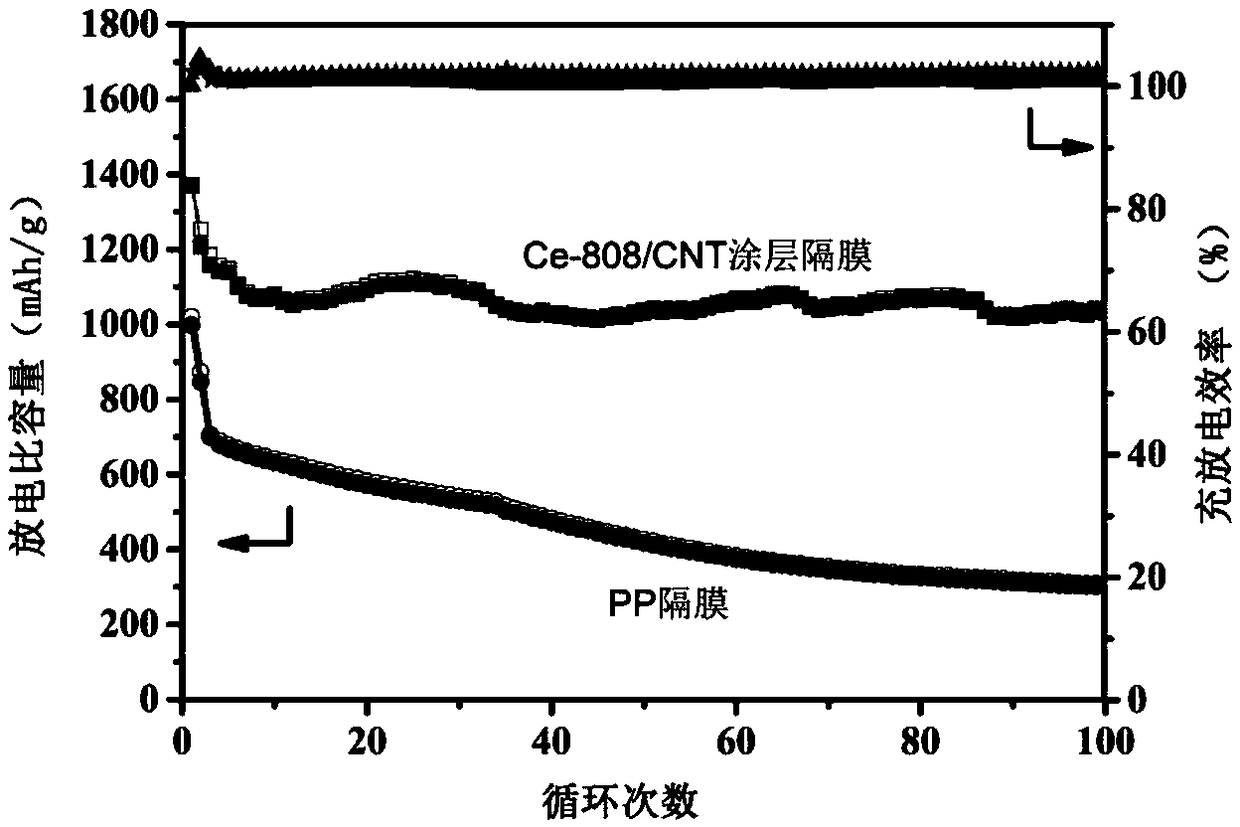

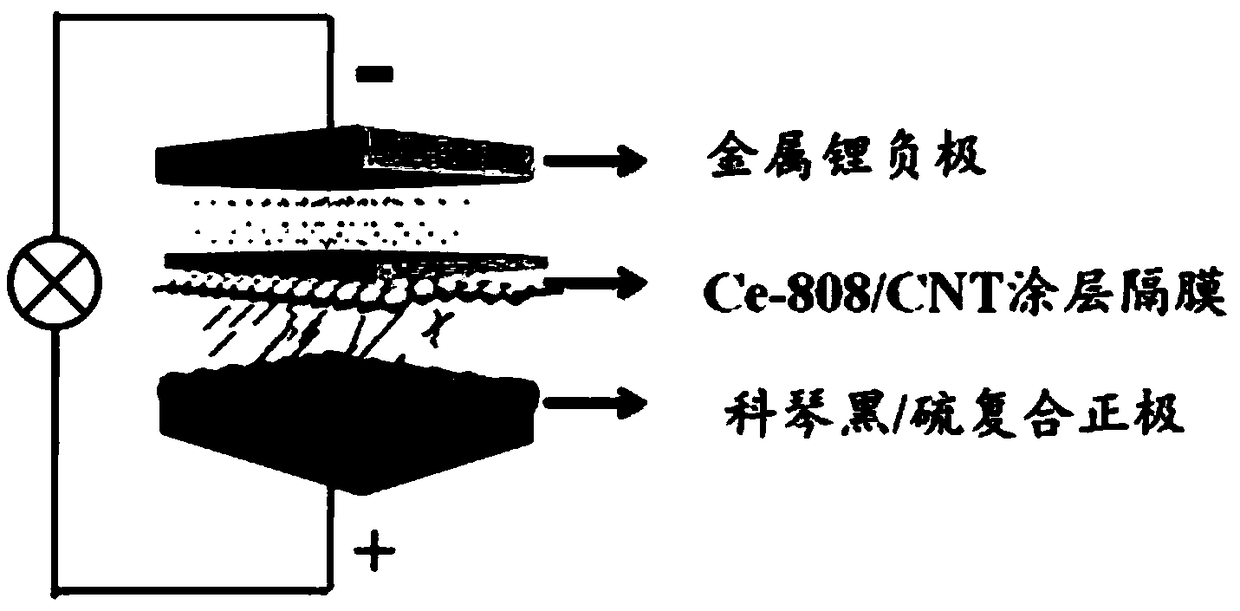

A metal-organic framework, carbon nanotube technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of reducing the overall energy density of the battery, reducing the capacity of lithium-sulfur batteries, limiting the dissolution of lithium polysulfides, etc., to suppress the shuttle effect. , the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The invention provides a method for preparing a metal-organic framework carbon nanotube composite material, comprising the following steps:

[0025] Step 1) Weigh trimesic acid and ammonium cerium nitrate with a molar ratio of 1:1, add a mixed solvent of organic solvent N,N-dimethylformamide and water and mix to obtain a mixed solution, and the ratio of the two is 5: 1;

[0026] Step 2) Put the mixed solution in an oil bath at a temperature of 80°C for 30 minutes to obtain a gray powder;

[0027] Step 3) The gray powder is washed with N,N-dimethylformamide and anhydrous methanol respectively;

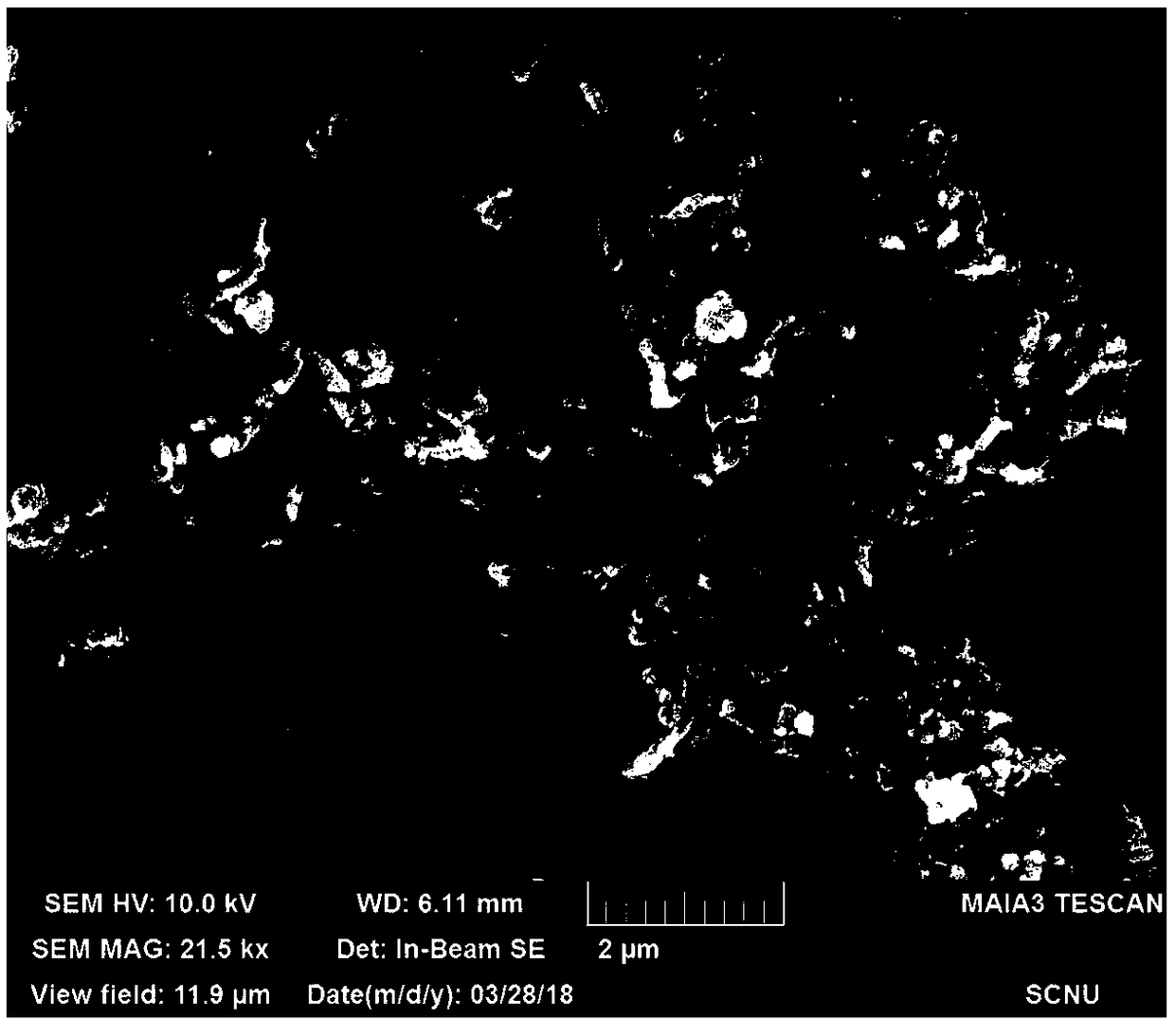

[0028] Step 4) Step 3) After drying, the nano-metal organic framework-carbon nanotube composite material is obtained after drying, and the SEM image of Ce-808 / CNT is referred to figure 1 .

[0029] In step 4), dry in a vacuum oven at a temperature of 60 °C.

[0030] A method for preparing a coating diaphragm based on the metal organic framework carbon nanotube composite mater...

Embodiment 2

[0032] A method for preparing a metal-organic framework carbon nanotube composite material, comprising the steps of:

[0033] Step 1) Weigh trimesic acid and ammonium cerium nitrate with a molar ratio of 1:1, add a mixed solvent of organic solvent N,N-dimethylformamide and water and mix to obtain a mixed solution, and the ratio of the two is 5: 1;

[0034] Step 2) Put the mixed solution in an oil bath at a temperature of 100°C for 30 minutes to obtain a gray powder;

[0035] Step 3) The gray powder is washed with N,N-dimethylformamide and anhydrous methanol respectively;

[0036] Step 4) Step 3) After drying, the nano-metal organic framework-carbon nanotube composite material is obtained after drying, and the SEM image of Ce-808 / CNT is referred to figure 1 .

[0037] In step 4), dry in a vacuum oven at a temperature of 70 °C.

[0038] A method for preparing a coating diaphragm based on the metal organic framework carbon nanotube composite material, characterized in that it...

Embodiment 3

[0040] A method for preparing a metal-organic framework carbon nanotube composite material, comprising the steps of:

[0041] Step 1) Weigh trimesic acid and ammonium cerium nitrate with a molar ratio of 1:1, add a mixed solvent of organic solvent N,N-dimethylformamide and water and mix to obtain a mixed solution, and the ratio of the two is 5: 1;

[0042] Step 2) Put the mixed solution in an oil bath at a temperature of 120°C for 30 minutes to obtain a gray powder;

[0043] Step 3) The gray powder is washed with N,N-dimethylformamide and anhydrous methanol respectively;

[0044] Step 4) Step 3) After drying, the nano-metal organic framework-carbon nanotube composite material is obtained after drying, and the SEM image of Ce-808 / CNT is referred to figure 1 .

[0045] In step 4), dry in a vacuum oven at a temperature of 80°C.

[0046]A method for preparing a coating diaphragm based on the metal organic framework carbon nanotube composite material, characterized in that it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com