Electro-catalytic conditioning energy wave superposition resonance sludge deep dehydrating method

A technology of deep dehydration and energy wave, applied in the direction of oxidation treatment sludge, electrochemical sludge treatment, chemical instruments and methods, etc., can solve the problems of energy consumption and environmental protection, and achieve condition control, simple method and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

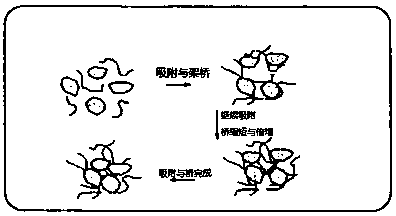

Image

Examples

Embodiment 1

[0047] Electroplating sludge to be treated: moisture content 80.2%; pH value 9.1; conductivity 438 ms / m; mud: water = 1:10; take 100 kg of the above sludge and put it in the reactor for chemical conditioning.

[0048] Step 1: Flocculation chemical conditioning, adding 0.75% concentration of PDADMAC and 0.28% concentration of acidic salt mixture for conditioning; after conditioning, transfer it to an electrochemical reactor for activation and catalysis;

[0049] Step 2: Electrochemical conditioning (catalytic activation), the conditions are: constant voltage 5.8-6.5 volts, pH value 7.2-7.5, catalytic reaction time 8-10 minutes, apparent ξ potential -15mv, apparent conductivity 620ms / m;

[0050] Step 3: Select wave resonance frequency 1500 (Hz), three-level resonance mode, and dehydrate under pressure drainage for 15-20 minutes;

[0051] Step 4: After deep drying, the moisture content of the sludge reaches 47-49%.

[0052] In summary, the method provided by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com