In-situ nitrogen-doped porous carbon nanofiber electrode material and macroscopic preparation method and application thereof

A nitrogen-doped porous carbon and carbon nanofiber technology, applied in the field of electrochemical energy storage, can solve the problems of electrochemical performance to be improved, complex synthesis process, low specific capacity, etc., achieve excellent electrochemical performance, simple synthesis process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

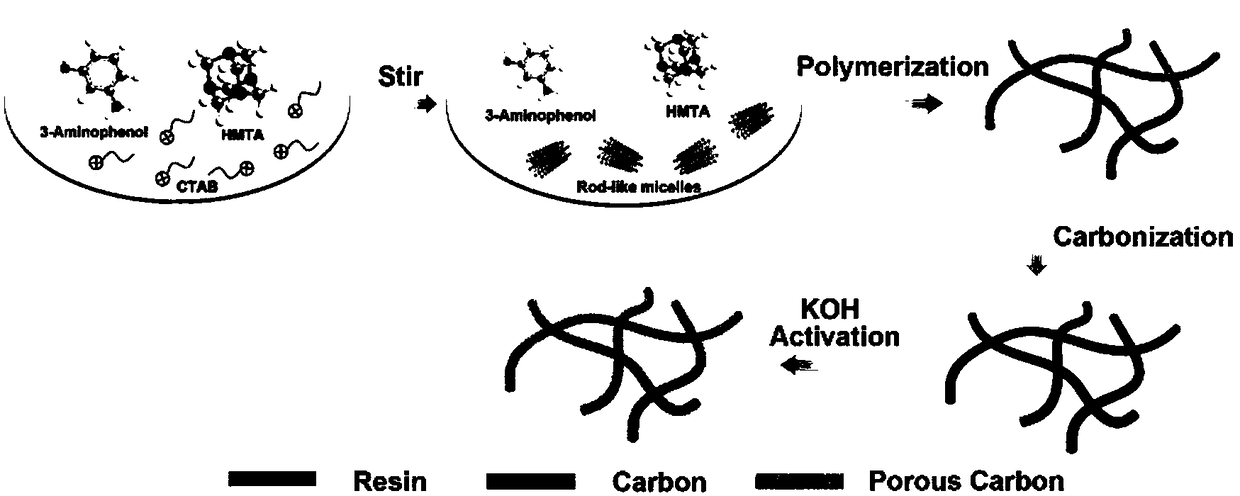

[0045] 1) Dissolve 0.2g of m-aminophenol and 0.514g of hexamethylenetetramine (HMTA) in 20ml of deionized water, add 0.15g of cetyltrimethylammonium bromide (CTAB), and stir for 20min. Transfer to an 85°C water bath for static reaction for 24 hours, freeze-dry to obtain brown phenolic resin nanofiber airgel;

[0046] 2) Calcinate the dried above sample in a tube furnace with nitrogen atmosphere at 800°C for 2h, with a heating rate of 2°C min -1 , to obtain carbon nanofiber airgel (CNF);

[0047]3) Grind and mix carbon nanofiber airgel and KOH evenly at a mass ratio of 1:4, calcinate in a tube furnace with nitrogen atmosphere at 700 °C for 2 h, and heat up at a rate of 2 °C min -1 . The carbonized sample was washed with 2M hydrochloric acid to remove excess impurities, and porous carbon nanofibers (ACNF) were obtained after drying.

[0048] Take the in-situ nitrogen-doped porous carbon nanofiber obtained in this example as an example. Its synthesis mechanism is as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com