The synthetic method of triphenylmethane

A technology of triphenylmethane and a synthesis method, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of long reaction time and difficulty in realizing industrial application, and achieves convenient post-processing and industrial application prospects. Considerable, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

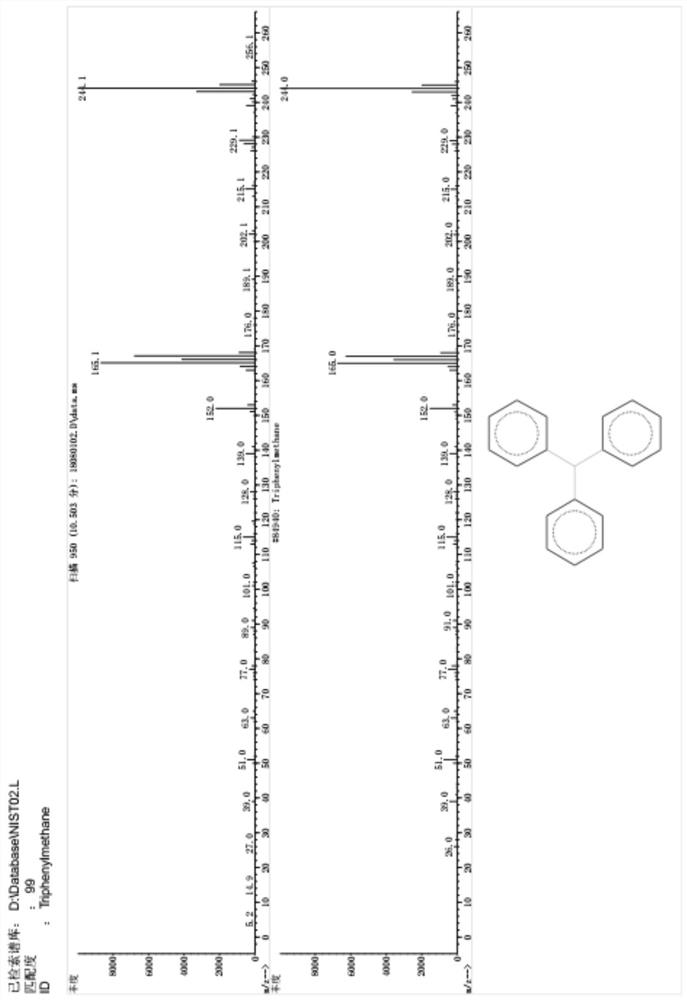

Image

Examples

Embodiment 1

[0057] The synthetic method of embodiment 1, triphenylmethane, carry out following steps successively:

[0058] (1) Under the protection of an inert gas (nitrogen), add 23g (1mol) of sodium, 300mL of toluene, and 4mL of oleic acid to the reaction device, heat up to reflux (110°C) and stir, stop heating after reflux for 1h, and stir at high speed until Cool to room temperature.

[0059] (2), under the protection of inert gas (nitrogen), slowly drop 56g (0.5mol) chlorobenzene and 50mL toluene mixed solution in step (1) gained liquid, the temperature of control reaction system is not more than 40 during the dropping process ℃; After the dropwise addition, react at 30℃ for 2h.

[0060] (3), under the protection of an inert gas (nitrogen), slowly drop the liquid obtained in step (2) into a mixed solution of 10g (0.25mol) acetonitrile and 30mL toluene, and the time for dropping is 30min. The reaction was stopped at 10°C for 3h.

Embodiment 2

[0065] The synthetic method of embodiment 2, triphenylmethane, carries out following steps successively:

[0066] (1), under the protection of an inert gas (nitrogen), add 23g (1mol) of sodium, 300mL of xylene, and 2g of sodium stearate into the reaction device, heat up to reflux (137°C) and stir, and stop heating after reflux for 1h. Stir on high speed until cool to room temperature.

[0067] (2), under the protection of inert gas (nitrogen), slowly drop 56g (0.5mol) chlorobenzene and 50mL xylene mixed solution in step (1) gained liquid, control the temperature of reaction system in the dropping process not to exceed 40°C; after the dropwise addition, react at 30°C for 2h.

[0068] (3), under the protection of an inert gas (nitrogen), slowly drop the liquid obtained in step (2) into a mixed solution of 8g (0.2mol) acetonitrile and 30mL xylene, the time for the addition is 30min, after the addition is completed Keep the reaction at 10°C for 3h, then stop.

[0069] (4) Add 1...

Embodiment 3

[0072] The synthetic method of embodiment 3, triphenylmethane, carries out following steps successively:

[0073] (1) Under the protection of an inert gas (nitrogen), add 23g (1mol) of sodium, 300mL of toluene, and 4mL of oleic acid to the reaction device, heat up to reflux (110°C) and stir, stop heating after reflux for 1h, and stir at high speed until Cool to room temperature.

[0074] (2), under the protection of inert gas (nitrogen), slowly drop 78.5g (0.5mol) bromobenzene and 80mL toluene mixed solution in the liquid obtained in step (1), control the temperature of the reaction system in the dropping process not to exceed 40°C; after the dropwise addition, react at 30°C for 2h.

[0075] (3), under the protection of an inert gas (nitrogen), slowly drop the liquid obtained in step (2) into a mixed solution of 10g (0.25mol) acetonitrile and 30mL toluene, and the time for dropping is 30min. React at 10°C for 3h to stop the reaction.

[0076] (4) Add 100 mL of 20% ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com