Preparation method of nylon 56 salt

A technology of nylon and pentamethylenediamine adipate, which is applied in the field of preparation of nylon 56 salt, can solve the problems of limited industrial production, high product cost, and high environmental protection pressure, and achieve easy operation, improved production efficiency, and increased output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a. In the lysine continuous fermentation and separation integrated system, the pH is controlled between 5.5. With the continuous generation of lysine, the pH in the system will continue to drop. In order to maintain a constant pH environment in the system, the fermentation tank The generated lysine fermentation liquid is filtered through an external inorganic ceramic membrane filter to obtain a primary filtrate of lysine. The bacterial residue is intercepted and then circulated back into the fermenter. With the continuous removal of lysine, new The lysine is continuously generated, and then filtered to realize the continuity of fermentation separation;

[0034] Among them, the lysine continuous fermentation and separation integrated system consists of a lysine fermentation tank, a circulation pump installed on the external circulation pipeline of the tank, and an external inorganic ceramic membrane filter;

[0035] The filtration accuracy of the external inorganic ceram...

Embodiment 2

[0049] a. In the lysine continuous fermentation and separation integrated system, the pH is controlled at 6. With the continuous generation of lysine, the pH in the system will continue to decrease. In order to maintain a constant pH environment in the system, the pH generated in the fermenter The lysine fermentation broth is filtered through an external inorganic metal membrane filter to obtain the primary filtrate of lysine. The bacterial residue is intercepted and then circulated back to the fermenter. With the continuous removal of lysine, the new lysine in the fermenter Amino acid is continuously generated, and then filtered to realize the continuity of fermentation separation;

[0050] Among them, the lysine continuous fermentation and separation integrated system consists of a lysine fermentation tank, a circulation pump on the external circulation pipeline of the tank, and an external inorganic metal membrane filter;

[0051] The filtration accuracy of the external ino...

Embodiment 3~4

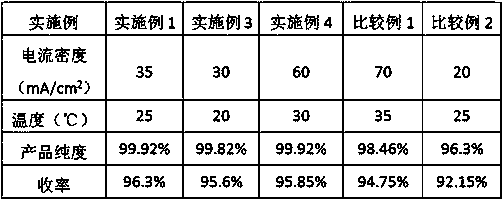

[0064] Embodiment 3~4, comparative example 1~2

[0065] The current density and temperature of the two-chamber bipolar membrane electrodialysis device were changed (see Table 1 for details), and other conditions were the same as in Example 1. The test results are shown in Table 1.

[0066] Table 1:

[0067]

[0068] As can be seen from Table 1, under the specific current density and temperature conditions of the present invention, the obtained product can be guaranteed to have higher purity and yield. Beyond the current density and temperature ranges defined by the present invention, the product purity and yield are significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com