Pulsed magnetic filtering and depositing device

A deposition device and pulsed magnetic technology, which are applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of complex ion valence, inability to achieve ion implantation, and inability to use surface modification, and achieve deposition low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

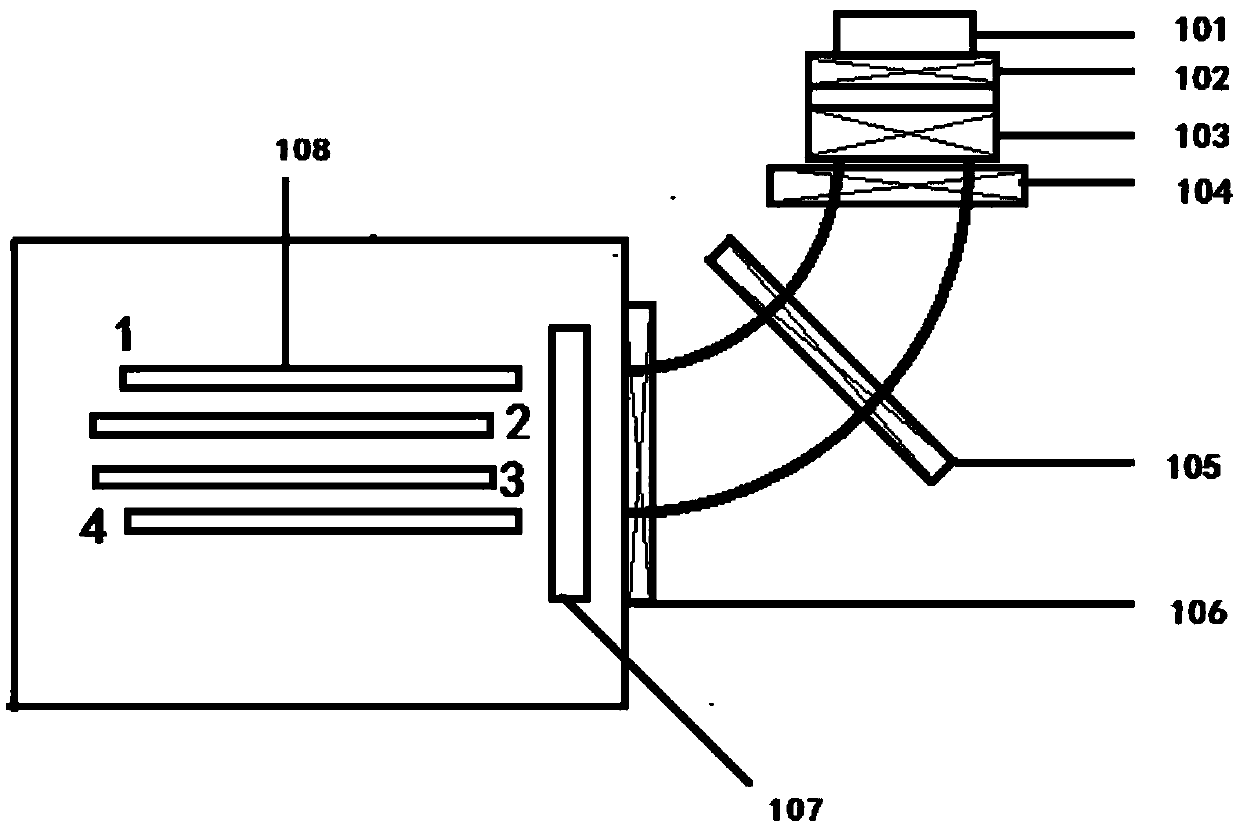

[0034] The trigger voltage is 5KV, the trigger frequency is 12Hz, and the pulse width is 100μs;

[0035] The lead-out electrode is 30mm away from the cathode surface;

[0036] The geometric center radius of the magnetic filter pipe is 160mm, the diameter is 80mm, and the magnetic filter angle is 90 degrees;

[0037] Transition line package: pass in a constant DC, the current intensity is 8A;

[0038] Bending wire package: pass in a strong pulse current, the current intensity is 80A, the pulse frequency is 8KHz, and the pulse width is 6000μs;

[0039] Focusing wire package: current intensity 1-100A, frequency 1-100Hz;

[0040] Grid: the size is Φ80mm, the grid aperture is Φ8mm, and the grid applies a negative pressure of 600V;

[0041] Quadrupole filter: filter DC voltage 400V, AC voltage 380V, frequency 5MHz.

Embodiment 2

[0043] The trigger voltage is 5KV, the trigger frequency is 12Hz, and the pulse width is 100μs;

[0044] The lead-out electrode is 30mm away from the cathode surface;

[0045] The geometric center radius of the magnetic filter pipe is 160mm, the diameter is 80mm, and the magnetic filter angle is 90 degrees;

[0046] Transition line package: pass in a constant DC, the current intensity is 8A;

[0047] Bending wire package: pass in a strong pulse current, the current intensity is 80A, the pulse frequency is 8KHz, and the pulse width is 6000μs;

[0048] Focusing wire package: current intensity 1-100A, frequency 1-100Hz;

[0049] Grid: the size is Φ80mm, the grid aperture is Φ10mm, and the grid applies a negative pressure of 600V;

[0050] Quadrupole filter: filter DC voltage 200V, AC voltage 380V, frequency 8MHz.

Embodiment 3

[0052] The trigger voltage is 5KV, the trigger frequency is 12Hz, and the pulse width is 100μs;

[0053] The lead-out electrode is 30mm away from the cathode surface;

[0054] The radius of curvature of the geometric center of the magnetic filter pipeline is 160mm, the diameter is Φ80mm, and the magnetic filter angle is 90 degrees; the transition line package: a constant DC is connected, and the current intensity is 8A;

[0055] Bending wire package: pass in a strong pulse current, the current intensity is 80A, the pulse frequency is 8KHz, and the pulse width is 6000μs;

[0056] Focusing wire package: current intensity 1-100A, frequency 1-100Hz;

[0057] Grid: the size is Φ80mm, the grid aperture is Φ10mm, and the grid applies a negative pressure of 300V;

[0058] Quadrupole filter: filter DC voltage 200V, AC voltage 380V, frequency 12MHz.

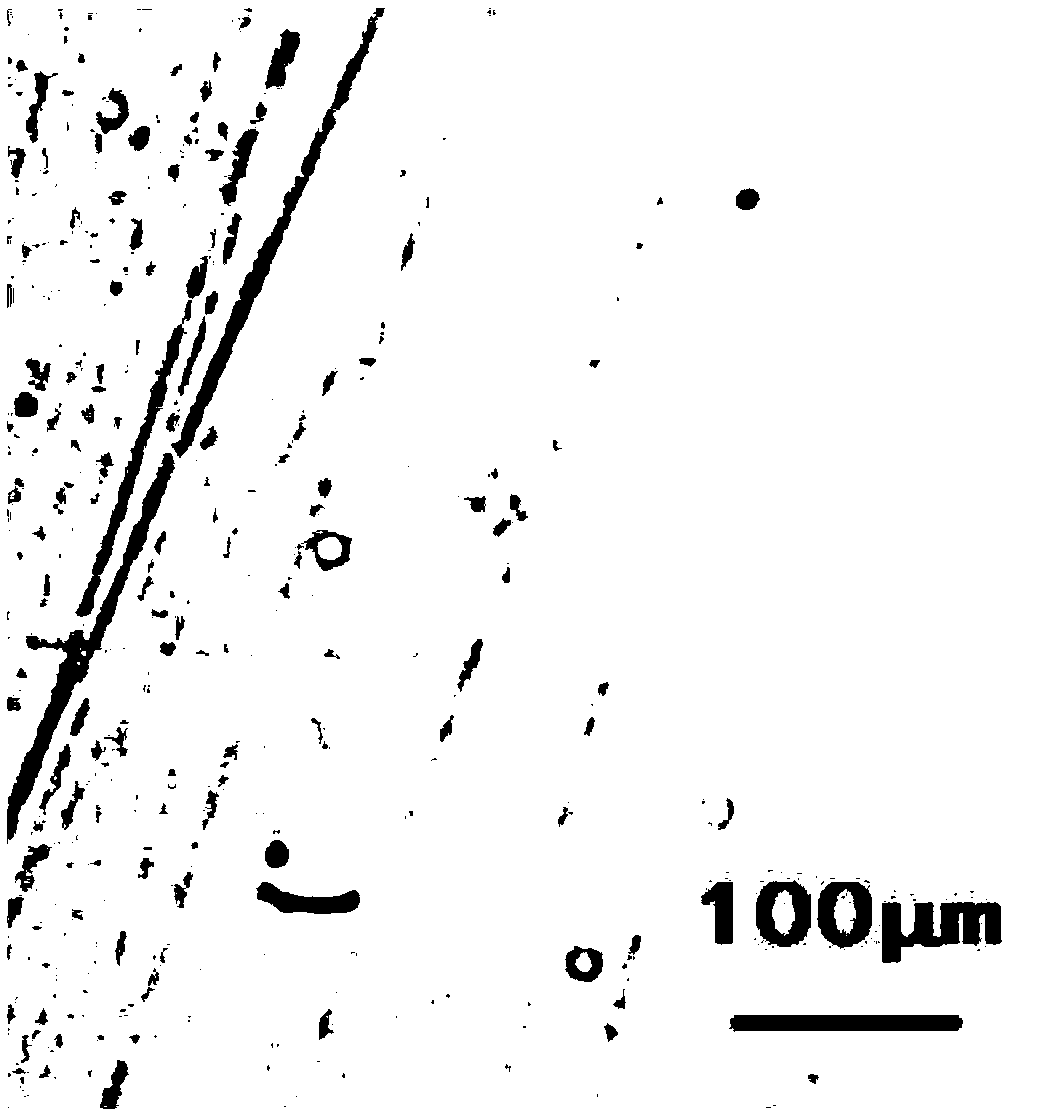

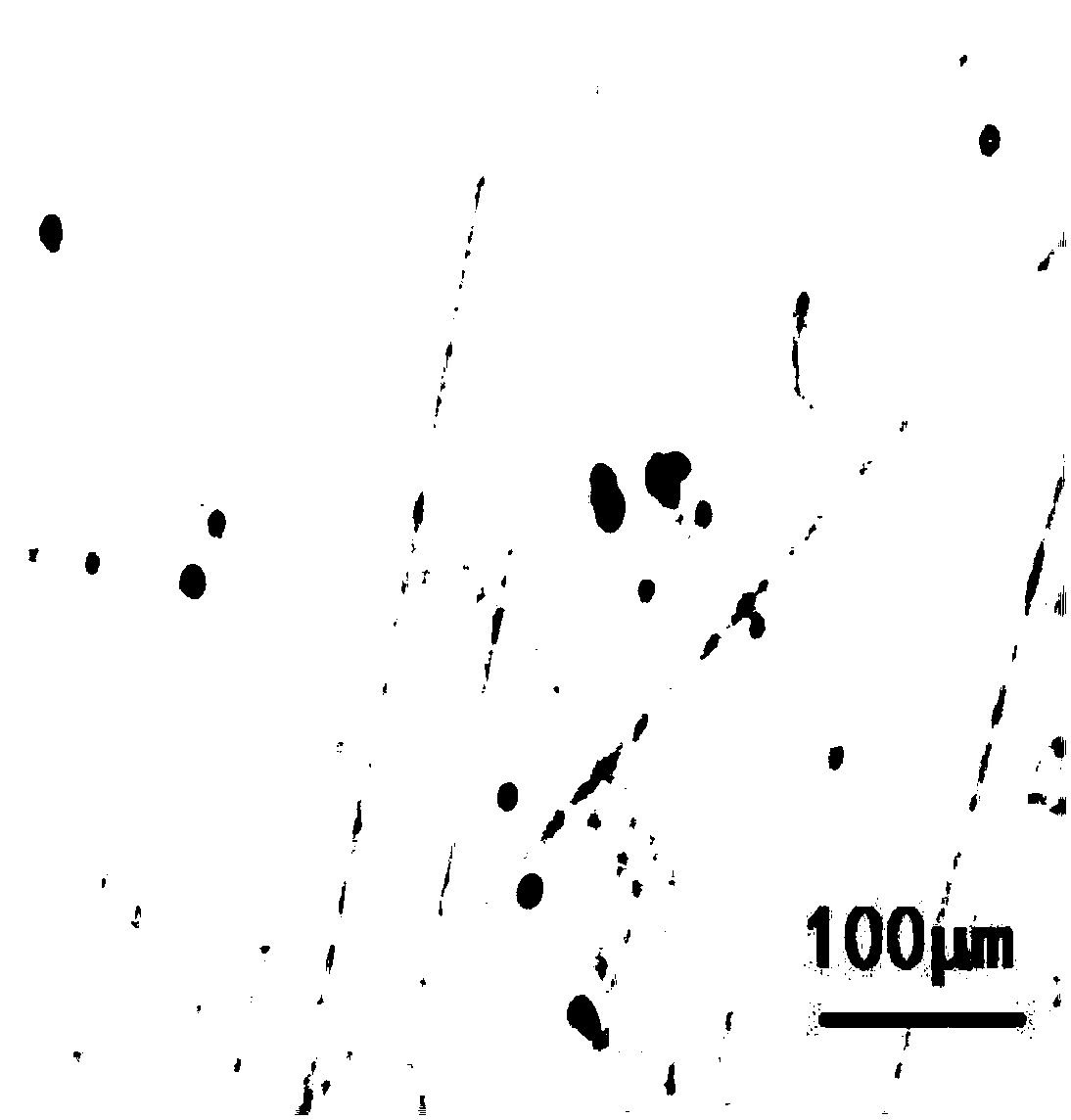

[0059] Figure 2-4 These are the optical topography diagrams of the metal nitride coatings prepared under the conditions of the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com