A Zwitterionic Membrane for All Vanadium Redox Flow Batteries

An all-vanadium redox flow battery, zwitterion technology, applied in the field of zwitterionic membranes and polymer membranes, can solve the problems affecting battery performance, vanadium ion penetration, self-discharge, etc., to improve vanadium resistance performance, good conductivity, reduce The effect of vanadium penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides a zwitterionic membrane for all-vanadium redox flow battery, which is prepared through the following steps:

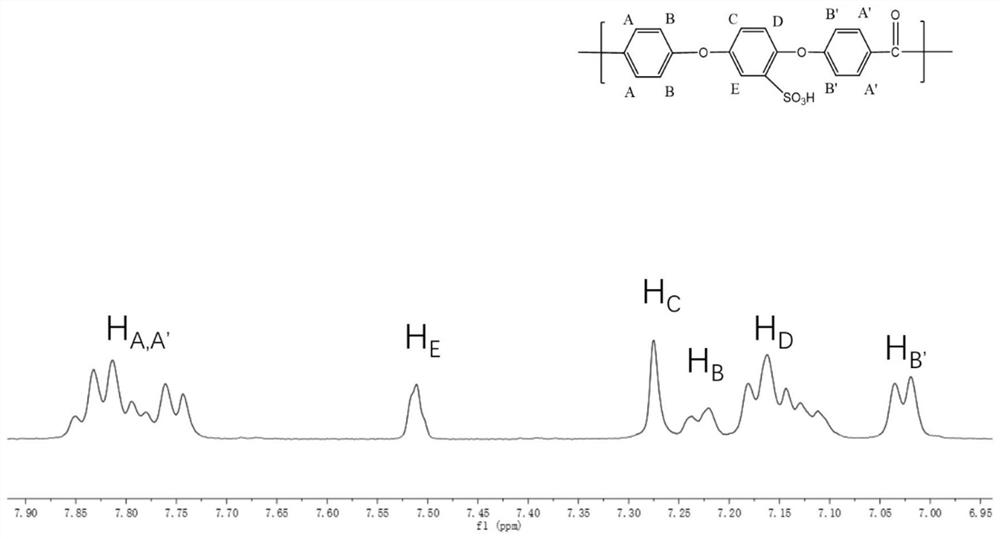

[0020] (a) Weigh 7.5g of polyether ether ketone and dissolve it in 150ml of concentrated sulfuric acid. After forming a homogeneous solution (that is, after dissolving evenly), heat it at 40°C for 10 hours, pour the reactant into ice water for precipitation, and wash it several times until Neutral, and finally dried in an oven at 80°C to obtain sulfonated polyether ether ketone, its NMR spectrum is as follows figure 1 Shown; And its general chemical structure formula is:

[0021]

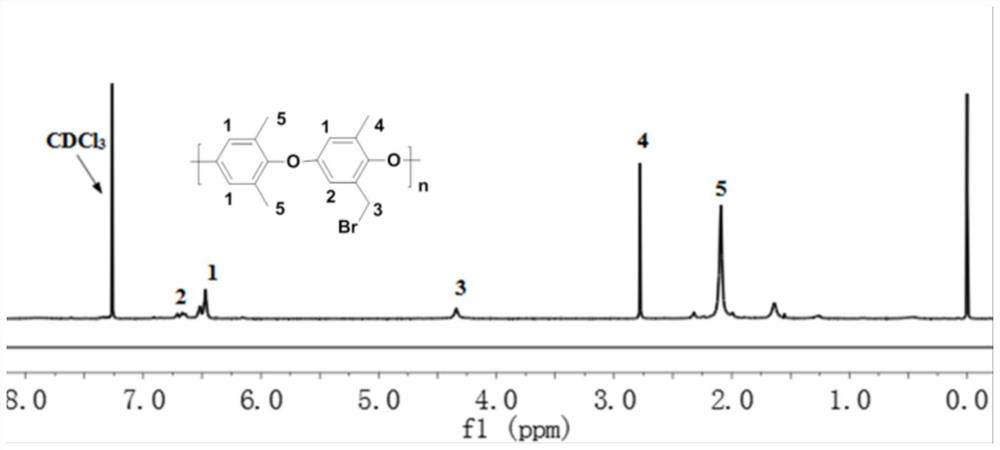

[0022] (b) Weigh 30ml of chlorobenzene and 6.00g of polyphenylene ether into a three-necked flask, protect the temperature with nitrogen to raise the temperature to 135°C, and weigh 1.78g of N-bromosuccinyl respectively after the polyphenylene ether is completely dissolved. Add imine and 0.16g AIBN to the mixture, stir and react at 135°C under nitrogen atm...

Embodiment 2

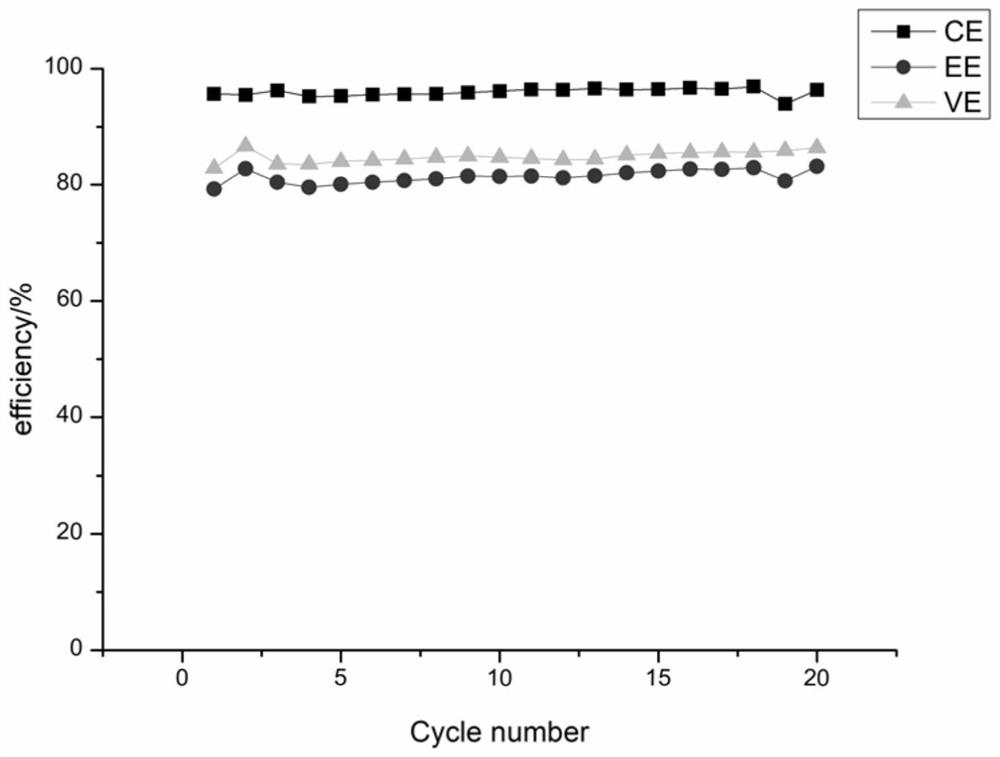

[0026] This embodiment provides a zwitterionic membrane for an all-vanadium redox flow battery, which is basically the same as that in Example 1, except that 1,2-dimethylimidazole is used in step (b), The general chemical formula of the finally obtained membrane is: Its performance parameters are: water absorption rate at room temperature is 33%, swelling degree is 15%, tensile strength is 16.52MPa, vanadium permeability coefficient is 2.89×10 -8 cm 2 / min, the conductivity at room temperature is 32mS / cm; the membrane is placed in 1.5mol / L VOSO 4 and 3mol / L H 2 SO 4 Soaked in the solution for 72 hours, the measured conductivity is 28mS / cm, which proves that it has good stability.

Embodiment 3

[0028] This embodiment provides a zwitterionic membrane for an all-vanadium redox flow battery, which is basically the same as 1 in the embodiment, except that: 1-ethylimidazole is used in step (b), and sulfonated Polyether ether ketone is blended to prepare a composite membrane, and its general structural formula is: The performance parameters of the finally obtained membrane are: water absorption rate at room temperature is 38%, swelling degree is 16%, tensile strength is 17.86MPa, vanadium permeability coefficient is 3.21×10 -8 cm 2 / min, the conductivity at room temperature is 33mS / cm; the membrane is placed in 1.5mol / L VOSO 4 and 3mol / L H 2 SO 4 Soaked in the solution for 72 hours, the measured conductivity is 31mS / cm, which proves that it has good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com