Benzenesulfonate amlodipine dispersible tablet and preparation method thereof

A kind of technology of amlodipine besylate and ammonia chloride sulfonate, applied in the field of amlodipine besylate dispersible tablet and preparation thereof, can solve the problems of low dissolution rate, poor stability and the like, and achieve high dissolution rate and good stability , the effect of controlling blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

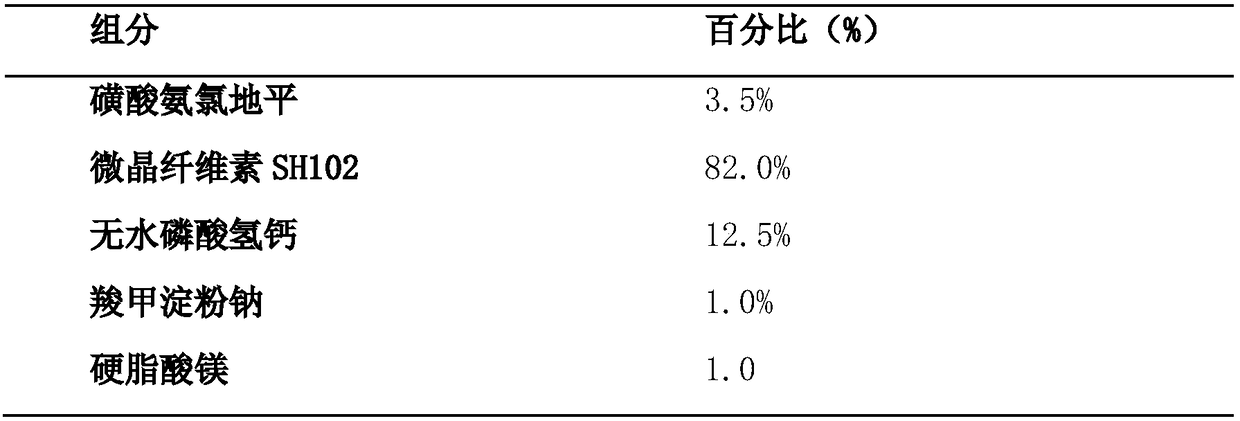

Embodiment 1

[0023]

[0024] Mix amlodipine besylate, carboxymethyl starch sodium and 1 / 3 microcrystalline cellulose according to the prescription amount for 8 minutes, and pass through a 40-mesh sieve. Add the remaining amount of microcrystalline cellulose and mix for 15 minutes; then add the prescribed amount of anhydrous calcium phosphate and mix for 25 minutes, and finally mix with magnesium stearate for 5 minutes, and compress into tablets.

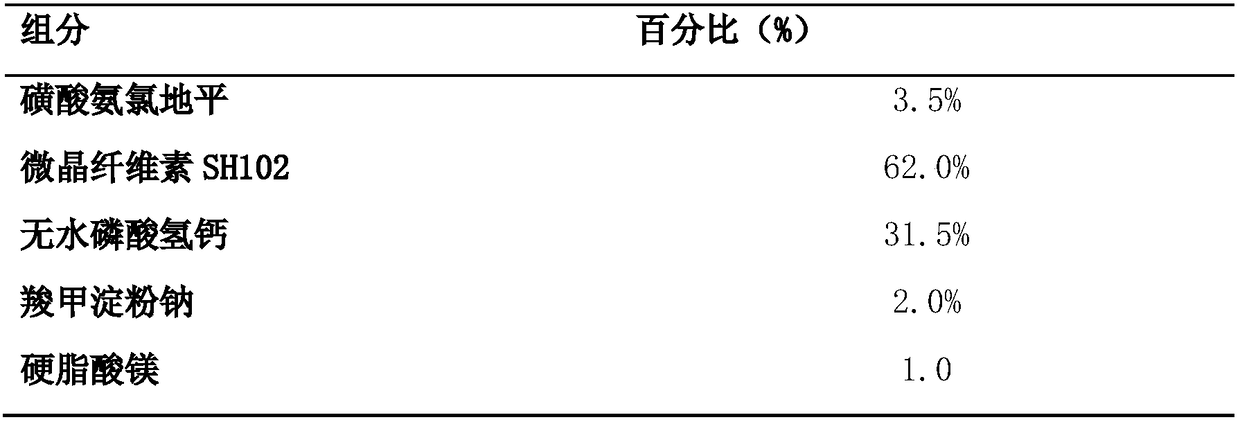

Embodiment 2

[0026]

[0027] Amlodipine besylate, sodium starch glycolate and 1 / 3 microcrystalline cellulose according to the prescription amount were mixed for 10 minutes and passed through a 40-mesh sieve. Add the remaining amount of microcrystalline cellulose and mix for 10 minutes; then add the prescribed amount of anhydrous calcium phosphate and mix for 20 minutes, and finally mix with magnesium stearate for 3 minutes, and press into tablets.

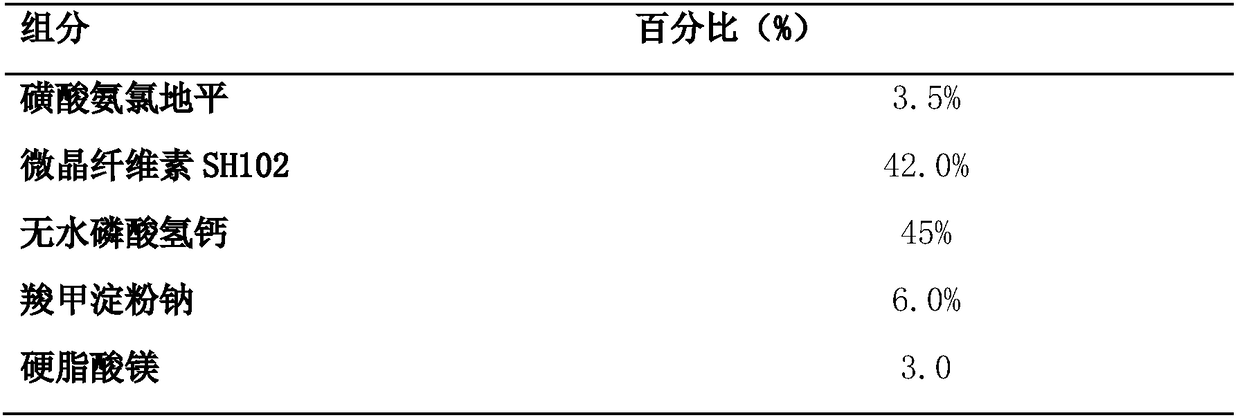

Embodiment 3

[0029]

[0030] Embodiment 1~3 compares (n=6, X ± SD) to commercially available common tablet amlodipine dissolution rate

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com