Composite passivating agent for copper alloy metal plate

A technology of passivating agent and metal plate, which is applied in the coating process of metal materials, etc., to achieve the effect of improving corrosion resistance, maintaining long-term stability, and good salt resistance

Inactive Publication Date: 2019-01-01

ANHUI UNIVERSITY OF TECHNOLOGY

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing passivators are difficult to meet the above requirements at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

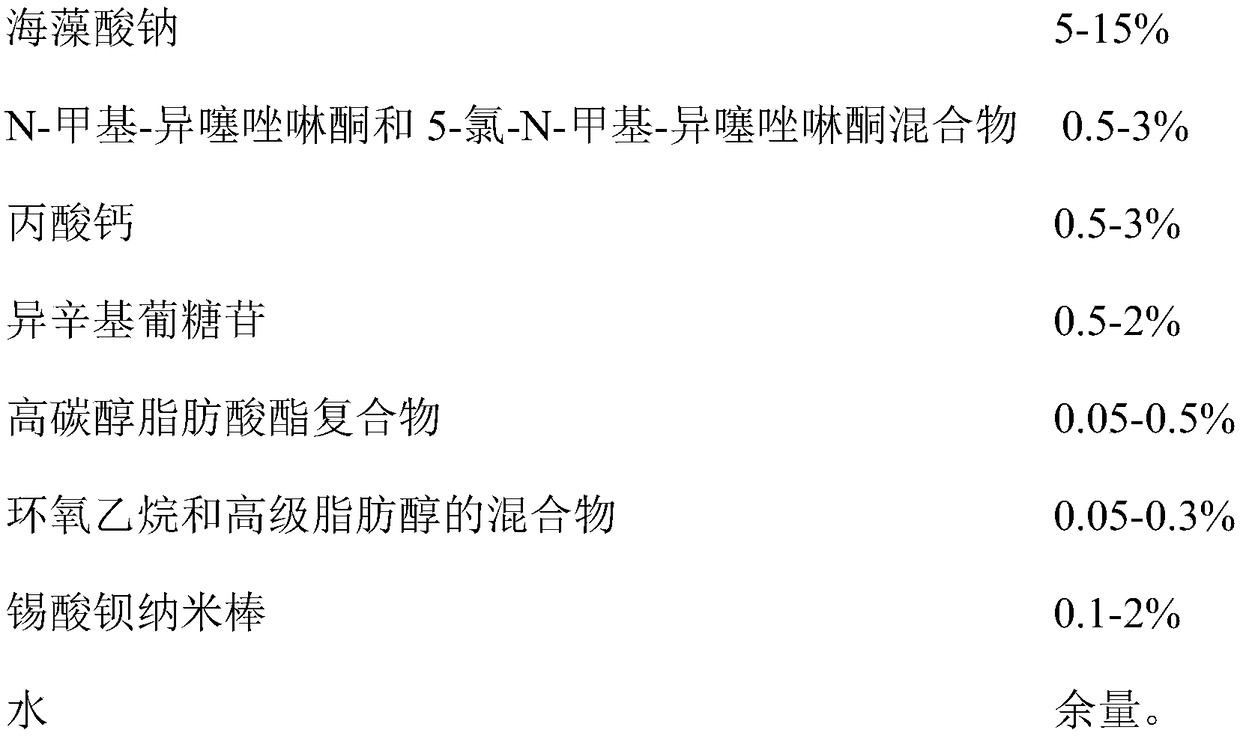

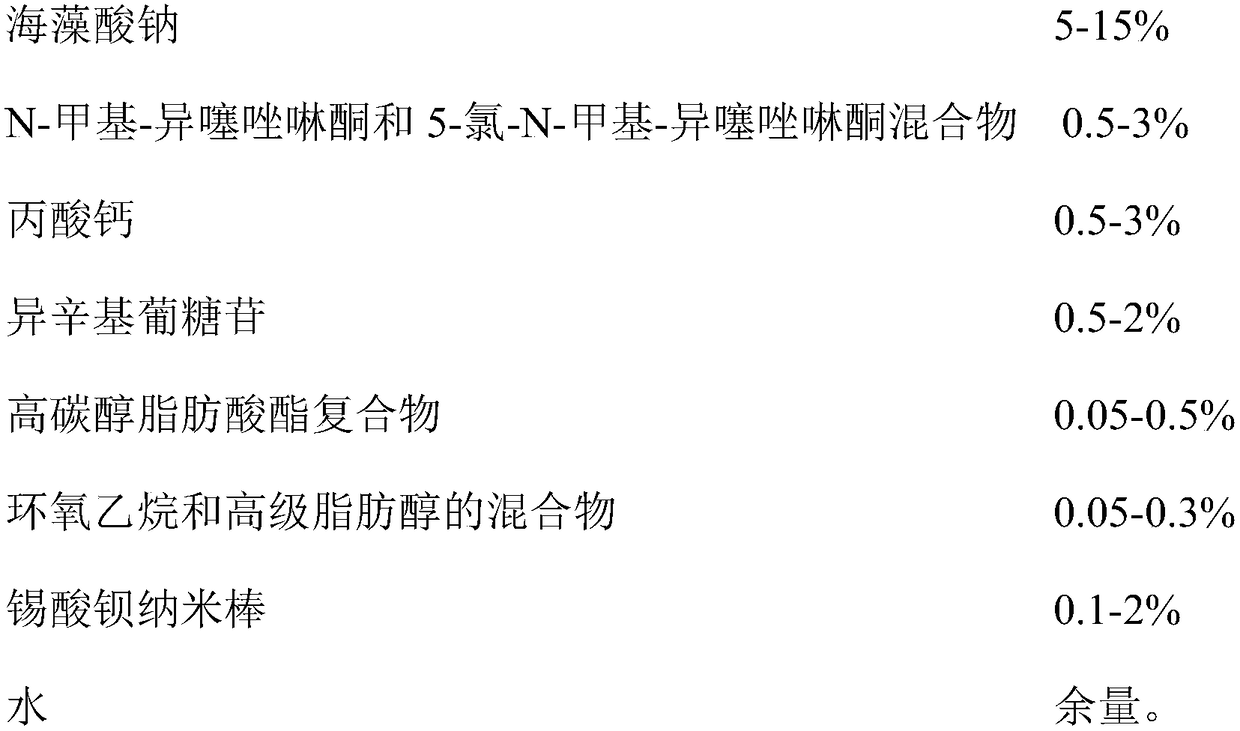

[0021] Determine the mass percent composition of the composite passivator for copper alloy metal plate as follows:

[0022]

Embodiment 2

[0024] Determine the mass percent composition of the composite passivator for copper alloy metal plate as follows:

[0025]

Embodiment 3

[0027] Determine the mass percent composition of the composite passivator for copper alloy metal plate as follows:

[0028]

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

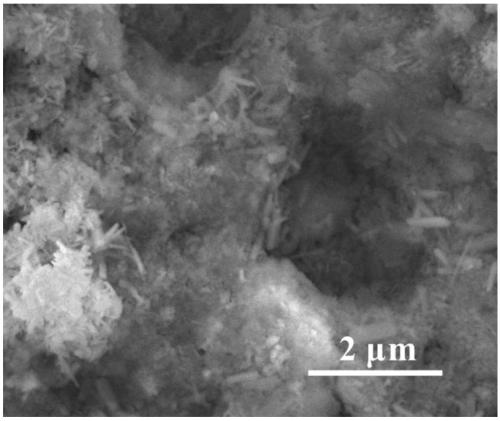

The invention discloses a composite passivating agent for a copper alloy metal plate, and belongs to the technical field of surface passivating treatment. The composite passivating agent is prepared from the following components in percentage by mass: 5 to 15% of sodium alginate, 0.5 to 3% of N-methyl-isothiazolinone and 5-chloro-N-methyl-isothiazolinone mixture, 0.5 to 3% of calcium propionate, 0.5 to 2% of isooctyl glucoside, 0.05 to 0.5% of high-carbon alcohol fatty acid ester complex, 0.05 to 0.3% of ethylene oxide and high-grade fatty alcohol mixture, 0.1 to 2% of barium stannate nanorod,and the balance of water, wherein the diameter of each barium stannate nanorod is 20 to 100nm, and the length is 500nm to 1mu m. The composite passivating agent has the advantages that the pretreatment before use is not required; after passivated by the composite passivating agent, the copper alloy metal plate has good salt resistance, weather resistance, water resistance, acid resistance, alkaline resistance, solvent resistance, fingerprint resistance and lubricating property.

Description

technical field [0001] The invention belongs to the technical field of surface passivation treatment, and in particular relates to a composite passivator for surface treatment of copper alloy metal plates. Background technique [0002] Copper alloy metal plates are widely used in the fields of electronics and decoration due to their excellent physical and chemical properties, but the chemical properties of copper are relatively active. It is easy to cause corrosion of the copper alloy metal plate and seriously affects the surface quality of the copper alloy metal plate. In order to improve the corrosion resistance, surface decoration and service life of the copper alloy metal plate, passivation treatment is required to form a passivation film with high density and high stability on the surface of the copper alloy metal plate. Passivation treatment is widely used due to its simple equipment and easy operation. The traditional passivation process mainly adopts chromate passi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C22/68

CPCC23C22/68

Inventor 裴立宅仇方吕

Owner ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com