Composite passivating agent for galvanized plate and aluminum alloy and copper alloy metal plate

A passivation agent, aluminum alloy technology, applied in the direction of metal material coating process, etc., to achieve good salt resistance and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

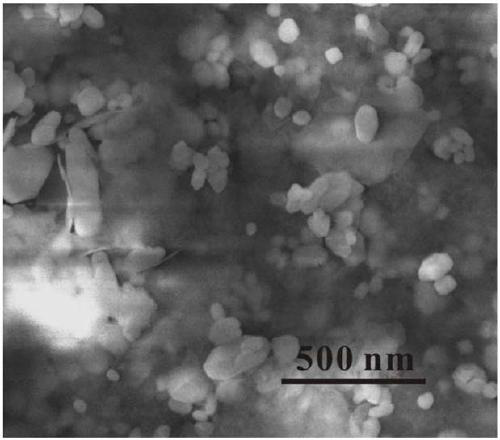

Image

Examples

Embodiment 1

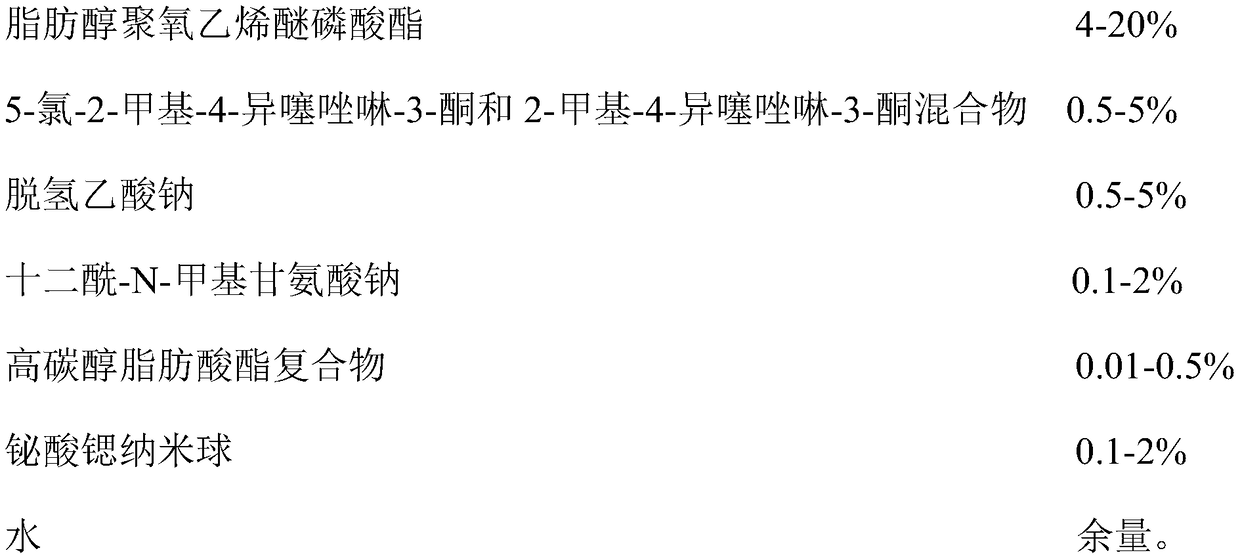

[0021] It is determined that the mass percent composition of the composite passivating agent for galvanized sheet, aluminum alloy and copper alloy metal plate is as follows:

[0022]

Embodiment 2

[0024] It is determined that the mass percent composition of the composite passivating agent for galvanized sheet, aluminum alloy and copper alloy metal plate is as follows:

[0025]

Embodiment 3

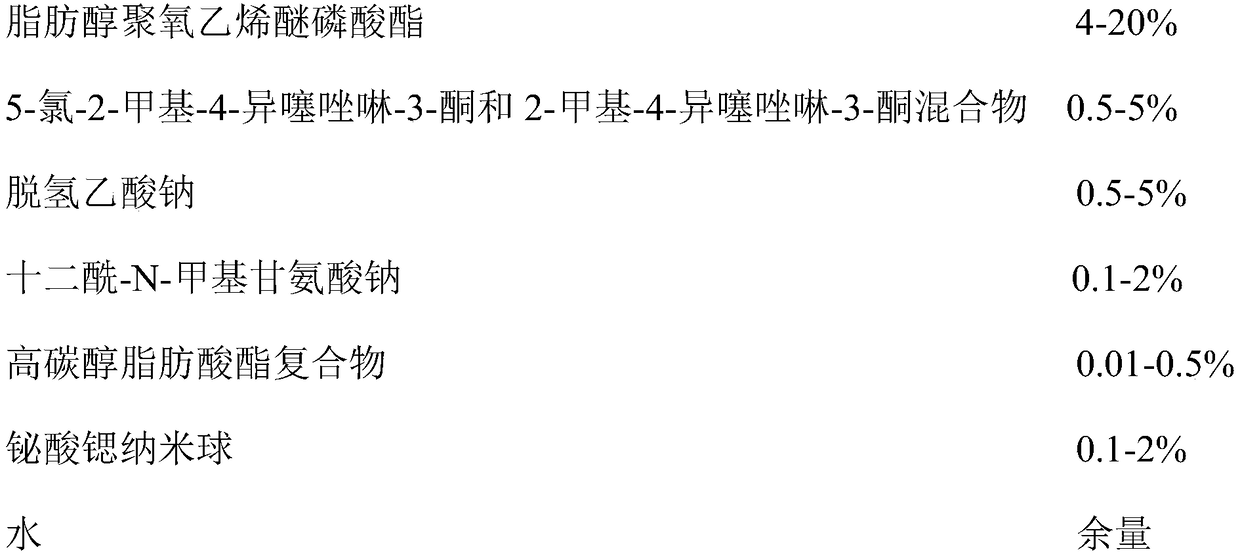

[0027] It is determined that the mass percent composition of the composite passivating agent for galvanized sheet, aluminum alloy and copper alloy metal plate is as follows:

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com