A solid-state polymer composite electrolyte and a preparation method and application thereof

A composite electrolyte and solid polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low ionic conductivity, poor mechanical properties, unsuitable batteries, etc., to improve ionic conductivity and reduce crystallization ability , the effect of increasing the content of the amorphous region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

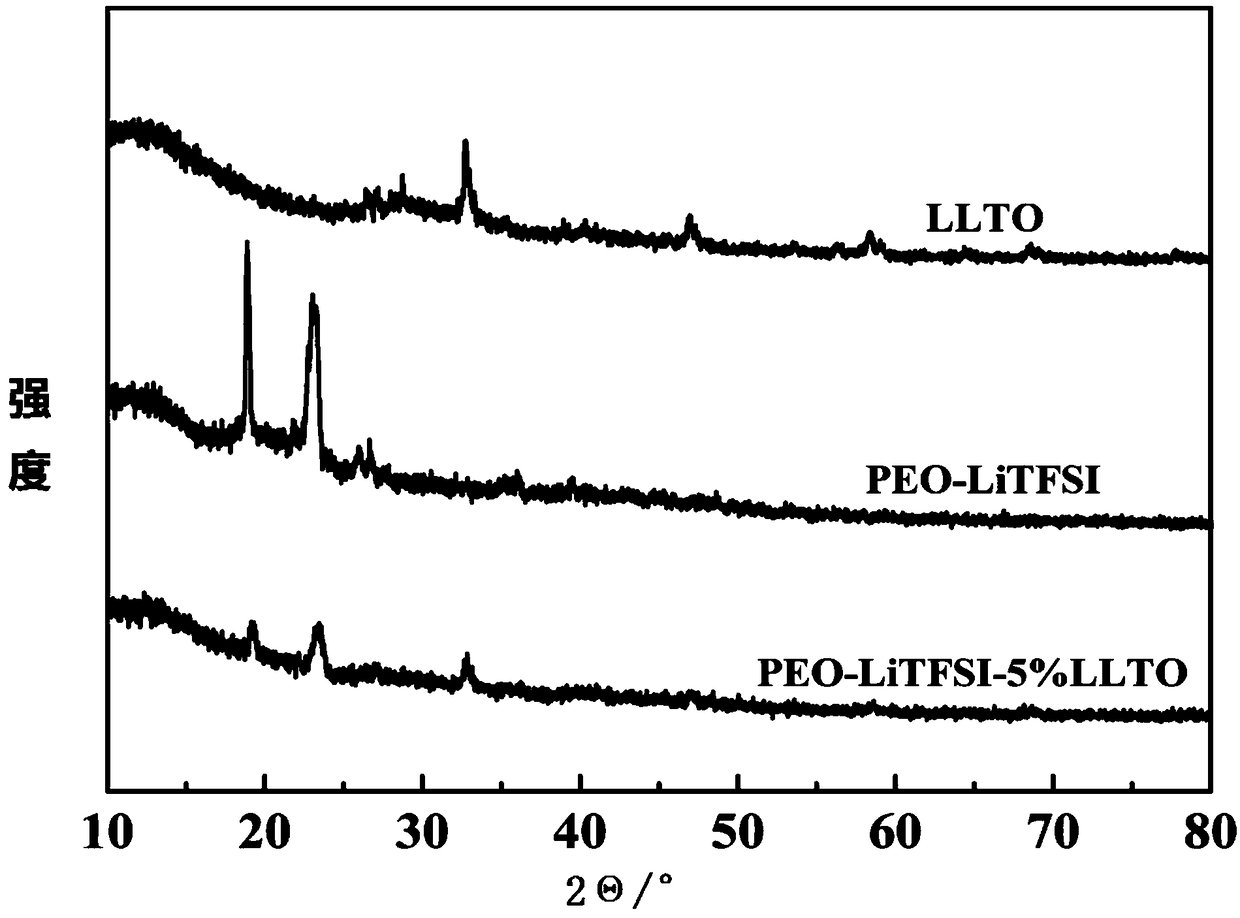

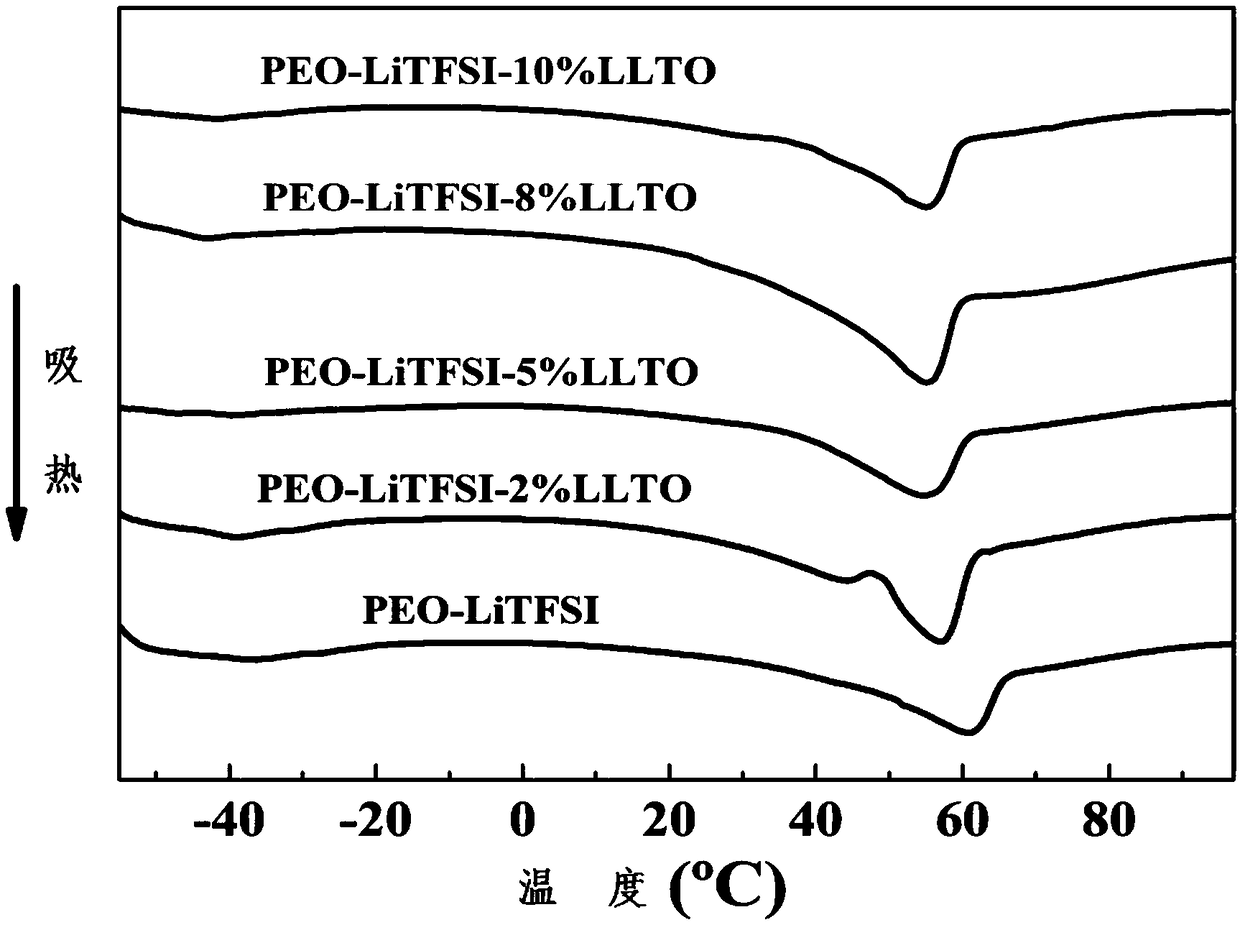

[0047]A solid polymer composite electrolyte (PEO-LiTFSI-5%LLTO) of the present invention is mainly composed of polyethylene oxide, lithium bistrifluoromethanesulfonylimide (LiTFSI) and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 composition, wherein the molar ratio of polyethylene oxide to LiTFSI is 18:1, polyethylene oxide and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 The mass ratio is 100:5.

[0048] The preparation method of the solid polymer composite electrolyte of this embodiment comprises the following steps:

[0049] (1) Weigh 0.36gLiTFSI and dissolve it in 30mL acetonitrile solvent to obtain a 12g / L lithium salt solution;

[0050] (2) Add 1.67g of quasi-one-dimensional lithium lanthanum titanyl Li in every liter of solvent 0.33 La 0.557 TiO 3 Proportioning, it was added to the lithium salt solution obtained in step (1), stirred for 6h, and ultrasonically 30min until uniform;

[0051] (3) Add polyethylene...

Embodiment 2

[0055] A solid polymer composite electrolyte (PEO-LiTFSI-2%LLTO) of the present invention, mainly composed of polyethylene oxide, lithium bistrifluoromethanesulfonylimide (LiTFSI) and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 composition, wherein the molar ratio of polyethylene oxide to LiTFSI is 18:1, polyethylene oxide and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 The mass ratio is 100:2.

[0056] The preparation method of the solid polymer composite electrolyte of this embodiment comprises the following steps:

[0057] (1) Weigh 0.36gLiTFSI and dissolve it in 40mL of acetonitrile solvent to obtain a 9g / L lithium salt solution;

[0058] (2) Add 0.5 g of quasi-one-dimensional lithium lanthanum titanyl Li per liter of solvent 0.33 La 0.557 TiO 3 Proportioning, it was added to the lithium salt solution obtained in step (1), stirred for 6h, and ultrasonically 30min until uniform;

[0059] (3) Add polyethylene oxi...

Embodiment 3

[0063] A solid polymer composite electrolyte (PEO-LiTFSI-8%LLTO) of the present invention is mainly composed of polyethylene oxide, lithium bistrifluoromethanesulfonylimide (LiTFSI) and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 composition, wherein the molar ratio of polyethylene oxide to LiTFSI is 18:1, polyethylene oxide and quasi-one-dimensional lithium lanthanum titanyl Li 0.33 La 0.557 TiO 3 The mass ratio is 100:8.

[0064] The preparation method of the solid polymer composite electrolyte of this embodiment comprises the following steps:

[0065] (1) Weigh 0.36gLiTFSI and dissolve it in 50ml acetonitrile solvent to obtain 7.2g / L lithium salt solution;

[0066] (2) Add 1.6 g of quasi-one-dimensional lithium lanthanum titanyl Li per liter of solvent 0.33 La 0.557 TiO 3 Proportioning, it was added to the lithium salt solution obtained in step (1), stirred for 6h, and ultrasonically 30min until uniform;

[0067] (3) Add polyethylene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com