Foam hand sanitizer and preparation method thereof

A hand sanitizer and foam technology, applied in the field of hand sanitizer, can solve the problems of unsatisfactory sterilizing effect, decontamination effect and no obvious synergistic effect, etc., and achieve good synergistic effect, good bactericidal effect, and fine foam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

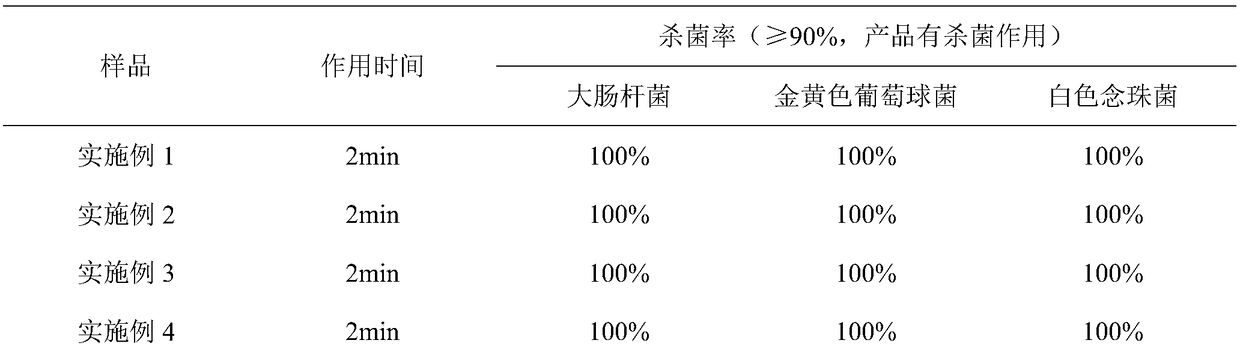

Embodiment 1

[0036] The foam hand sanitizer of the present embodiment is made up of the following components in mass percentage: chlorhexidine type disinfectant 0.1%, surfactant 10%, emollient 0.3%, pH regulator 0.2%, essence 0.1%, remaining The amount is water.

[0037] The chlorhexidine disinfectant is chlorhexidine gluconate.

[0038] The surfactant is a mixture of alkyl glucoside and fatty alcohol polyoxyethylene ether, and the mass ratio of alkyl glycoside to fatty alcohol polyoxyethylene ether is 2:1. Alkyl glycoside The alkyl chain length of the alkyl glycoside is 12 to 16 carbons.

[0039] The emollient is glycerol.

[0040] The pH regulator is citric acid.

[0041] The essence is lily essence.

[0042] The preparation method of the foam hand sanitizer of the present embodiment may further comprise the steps:

[0043] 1) Take the formulated amount of water, heat the water to 45°C, add the formulated amount of surfactant, stir to dissolve the surfactant, and obtain a primary diss...

Embodiment 2

[0048] The foam hand sanitizer of the present embodiment is made up of the following components in mass percentage: 0.3% of chlorhexidine disinfectant, 15% of surfactant, 2% of emollient, 0.3% of pH regulator, 0.05% of essence, and The amount is water.

[0049] The chlorhexidine disinfectant is chlorhexidine gluconate.

[0050] The surfactant is a mixture of alkyl glucoside and polyethylene glycol, and the mass ratio of alkyl glycoside and polyethylene glycol in the mixture of alkyl glycoside and polyethylene glycol is 3:1. Alkyl glycoside The alkyl chain length of the alkyl glycoside is 12 to 16 carbons. The polyethylene glycol is PEG400 with an average molecular weight of 400.

[0051] The emollient is aloe vera extract. The extraction method of aloe extract comprises the following steps:

[0052] 1) Take Aloe vera leaves and mash them into aloe meat, add 3mL of methanol hydrochloride with a volume concentration of 2% for every 1g of aloe meat, the volume fraction of hyd...

Embodiment 3

[0065] The foam hand sanitizer of the present embodiment is made up of the following components in mass percentage: 0.5% of chlorhexidine disinfectant, 18% of surfactant, 3% of emollient, 0.3% of pH regulator, 0.1% of essence, and The amount is water.

[0066] The chlorhexidine disinfectant is chlorhexidine acetate.

[0067] The surfactant is a mixture of coconut oil fatty acid diethanolamide and fatty alcohol polyoxyethylene ether, and the mass ratio of coconut oil fatty acid diethanolamide to fatty alcohol polyoxyethylene ether is 2:1.

[0068] The emollient is glyceryl polyether.

[0069] The pH regulator is citric acid.

[0070] The essence is lily essence.

[0071] The preparation method of the foam hand sanitizer of the present embodiment may further comprise the steps:

[0072] 1) Take the formulated amount of water, heat the water to 40°C, add the formulated amount of surfactant, stir to dissolve the surfactant, and obtain the primary dissolved substance;

[0073]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com