Preparation method of CdS/g-C3N4 dual-nanosheet composite photocatalyst

A technology of g-c3n4 and nanosheets, applied in the field of photocatalysis, can solve the problems of narrow band gap of CdS, affecting the photocatalytic activity, restricting the development of CdS, etc., so as to improve the photocatalytic activity, weaken the photocorrosion phenomenon, and enhance the photocatalysis. active effect

Active Publication Date: 2019-01-04

EAST CHINA UNIV OF SCI & TECH

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a way to work with g-C 3 N 4 Composite narrow-bandgap semiconductor material, cadmium sulfide (CdS) has a negative reduction potential and strong reduction ability, but due to the narrow bandgap width of CdS, it is unstable and prone to photocorrosion under light, which affects the photocatalytic activity. Seriously limit the development of CdS in the field of photocatalysis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0035] CdS / g-C 3 N 4 Preparation of double nanosheets

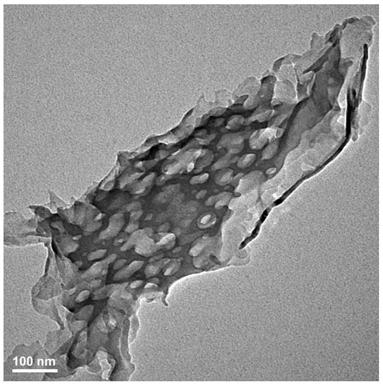

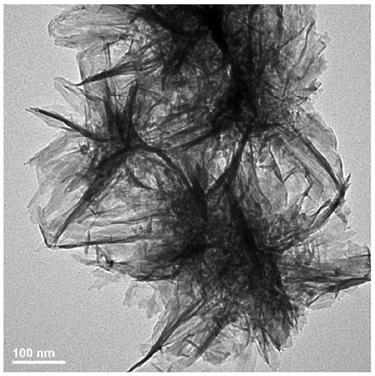

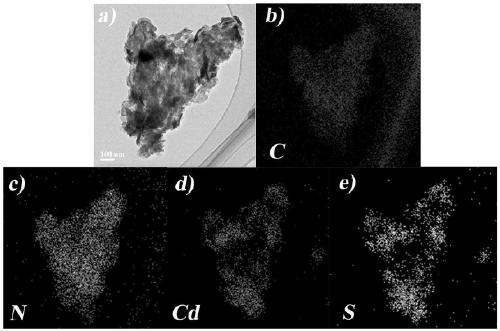

[0036] 79.04mg of CdCl 2 2.5H 2 O was dispersed in 30mL DETA, placed in a 100mL flask, ultrasonically dispersed and then added 68.67mg S powder and 50mg g-C 3 N 4 After stirring the nanosheets evenly, put the flask into an oil bath at 80°C for 10 hours. After cooling to room temperature, it was washed by centrifugation and dried to obtain CdS / g-C 3 N 4 double nanosheets.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of a CdS / g-C3N4 dual-nanosheet composite photocatalyst. The method comprises, through a gas template method, mixing and grinding a gas template and carbon nitride precursor to sinter within one step in inert atmosphere to obtain a g-C3N4 nanosheet, then adding the prepared g-C3N4 nanosheet into diethylenetriamine (DETA) solution containing cadmium chloride hemihydrate (CdCl2*2.5H2) and powdered sulfur (S) to react under oil bath heating to prepare a CdS / g-C3N4 material in a special structure, namely, a dual-nanosheet structure. The preparation methodof the CdS / g-C3N4 dual-nanosheet composite photocatalyst applies a semiconductor compositing method; when applied to photocatalytic H2O2 production, CdS / g-C3N4 dual-nanosheets can be highly effectivein catalytic activity effectively improve the photocatalytic activity of g-C3N4 nanosheets as well as effectively weaken photo-corrosion of CdS, thereby having a good application prospect in the photocatalytic fields such as photocatalytic hydrogen production, CO2 reduction and organic pollutant degradation.

Description

technical field [0001] The invention relates to a photocatalytic material capable of efficiently preparing hydrogen peroxide, belonging to the field of photocatalysis. Background technique [0002] Hydrogen peroxide is a clean, environment-friendly oxidant, and only water is used as a by-product in the reaction. It is widely used in industrial organic synthesis, pulp bleaching, wastewater treatment and sterilization. At the same time, hydrogen peroxide is also considered to be a new generation of clean energy. At present, the industrial production of hydrogen peroxide is mainly based on the anthraquinone method, which requires multiple hydrogenation and oxidation steps, consumes a lot of energy and pollutes the environment. Some researchers use hydrogen (H 2 ) and oxygen (O 2 ) directly prepare hydrogen peroxide under the catalysis of palladium (Pd) or gold-palladium alloy (Au-Pd), while hydrogen / oxygen (H 2 / O 2 ) mixed gas is prone to explosion. Therefore, developing ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J27/24B01J37/08B01J35/10B82Y30/00B82Y40/00C01B15/027

CPCB82Y30/00B82Y40/00C01B15/027B01J27/24B01J37/082B01J35/39B01J35/60

Inventor 张金龙雷菊英江振颖刘勇弟王灵芝郑家豪张嘉宽姜森

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com