Method for preparing gypsum-based plastering material

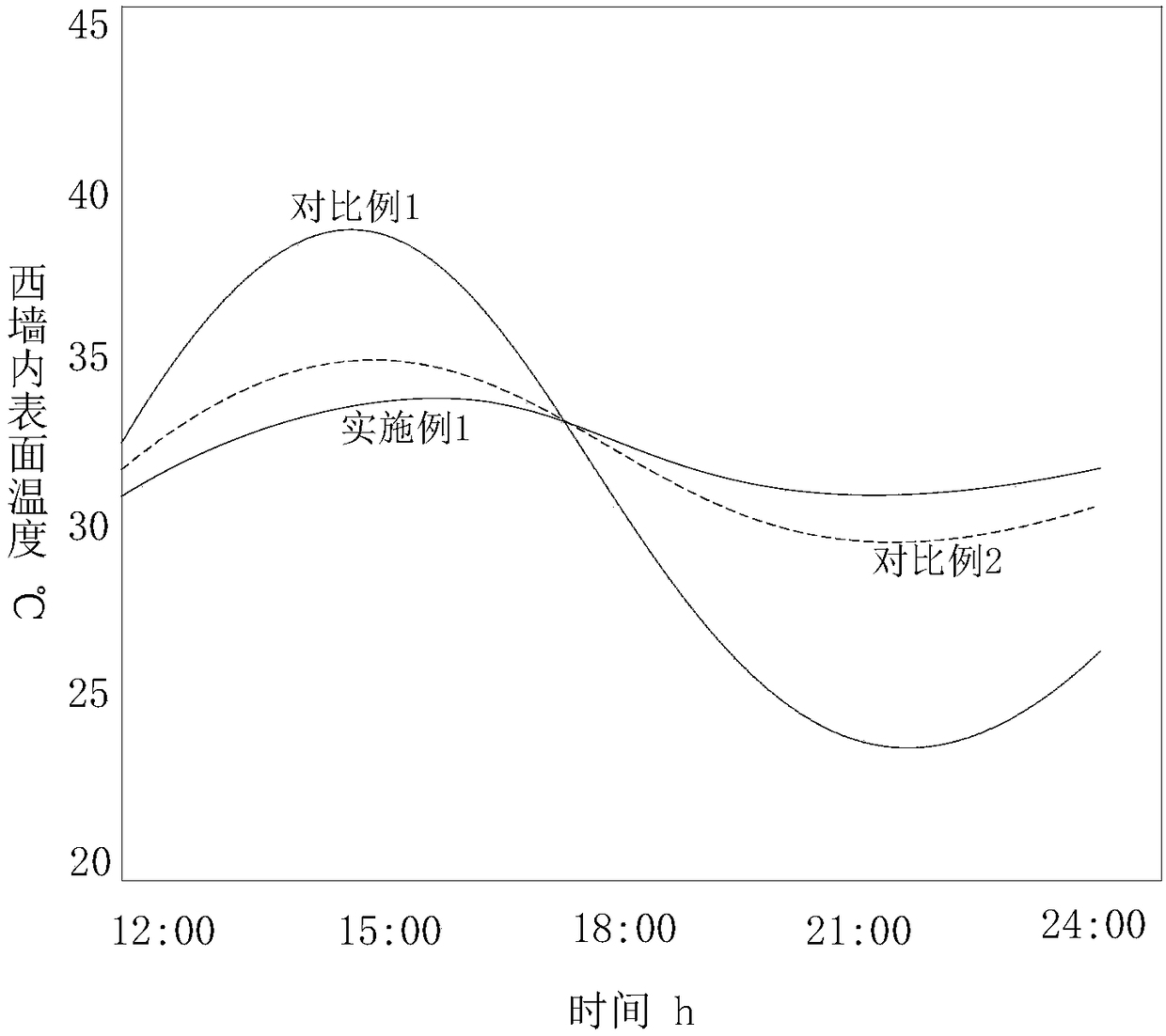

A gypsum-based, heat-storage material technology, applied in the field of new building materials, can solve the problems of poor performance of gypsum products, separation of the board core and paper core, and frost on the surface, and achieves improved living comfort, improved thermal insulation performance, and strong adsorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

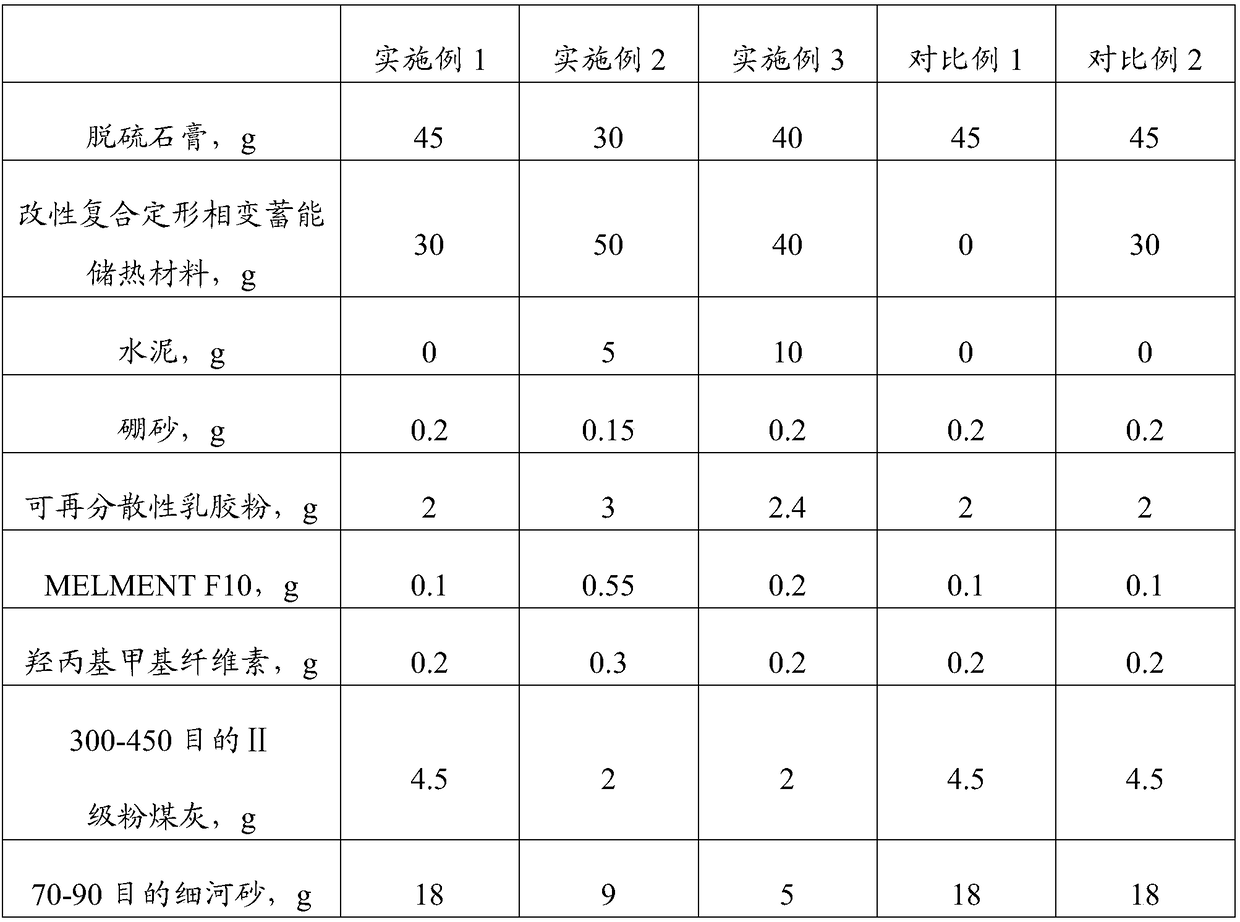

[0054] 2. Preparation of gypsum-based plastering materials

[0055] Step 1: Weigh each component according to the mass in Table 1;

[0056] Step 2: Mix the desulfurized gypsum, the modified composite phase change energy storage heat storage material, and the retarder evenly, and put them into a constant temperature and constant pressure vacuum drying oven at a temperature of 40±2°C and a vacuum of -0.08MPa. Vacuum for 10 minutes;

[0057] Step 3: Blend the premixed powder obtained in step 2 with fly ash and sands of different particle sizes, and filter out 70-90 mesh fine river sand by optimizing the particle gradation of the mixture, and mix evenly;

[0058] Step 4: uniformly mix the premixed powder obtained in step 3 with cement, water reducer, latex powder, and cellulose ether to prepare the gypsum-based plastering material.

[0059] 3. Preparation of gypsum-based plastering mortar

[0060] The gypsum-based plastering material prepared above is mixed with mixing water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com