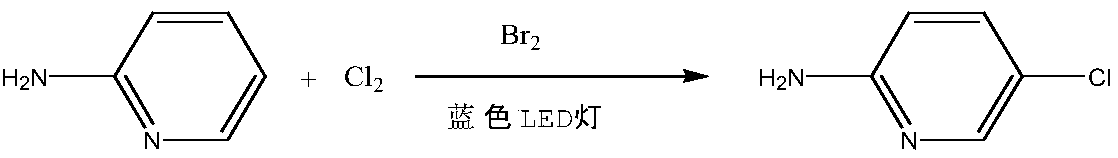

Method using one-step method to synthesize 2-amino-5-chloropyridine in high-selectivity manner

A high-selectivity, aminopyridine technology, applied in the field of one-step high-efficiency and high-selectivity synthesis of 2-amino-5-chloropyridine, can solve the problems of difficult product separation and purification, unavoidable dichlorides, and unsuitability for industrial production. Achieve the effect of high product purity, less waste water and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Under the irradiation of a 34W blue LED lamp, add 20g (0.21mol) of 2-aminopyridine and 200mL of acetone to a 500mL three-neck round-bottomed flask in sequence, stir and dissolve, then add 3.4g (0.021mol) of bromine. Add about 16 g of chlorine gas, react for 3 h, recrystallize with methanol, and dry to obtain 24.6 g of 2-amino-5-chloropyridine-like white crystals with a GC purity of 99.6% and a molar yield of 90.0%.

Embodiment 2

[0026] Under the irradiation of a 34W blue LED lamp, 20g (0.21mol) of 2-aminopyridine and 200mL of acetonitrile were successively added to a 500mL three-necked round-bottomed flask, and 1.8g (0.011mol) of bromine was added after stirring and dissolving. Add about 30 g of chlorine gas, react for 2 h, recrystallize with methanol, and dry to obtain 25.7 g of 2-amino-5-chloropyridine-like white crystals with a GC purity of 99.4% and a molar yield of 99.4%.

Embodiment 3

[0028] Under the irradiation of a 32W blue LED lamp, add 20g (0.21mol) of 2-aminopyridine and 200mL of dichloromethane to a 500mL three-necked round-bottomed flask, stir and dissolve, then add 1.8g (0.011mol) of bromine, and after the solution fades, Then, about 20 g of chlorine gas was introduced, reacted for 4 h, recrystallized by ethanol, and dried to obtain 26.1 g of 2-amino-5-chloropyridine-like white crystals with a GC purity of 99.6% and a molar yield of 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com