Polyester peptide vesicle with inner membrane with negative charges and preparation method and application of polyester peptide vesicle

A technology of polyester and vesicles, which is applied in the fields of polymer materials and applied chemistry, can solve problems such as low protein encapsulation efficiency, and achieve the effects of high protein encapsulation capacity, good application prospects and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

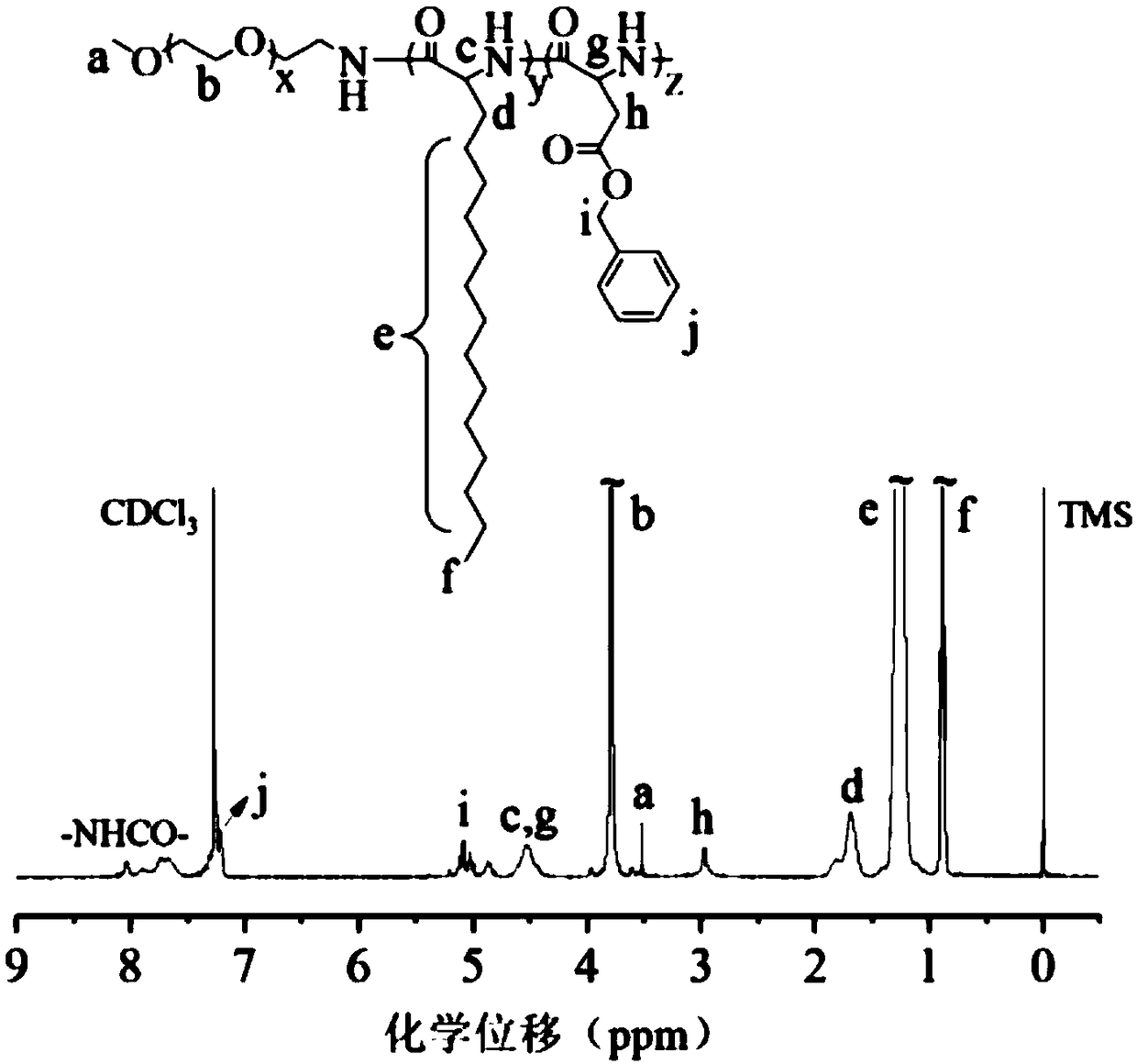

[0037] Example 1: Polyethylene glycol-b-poly(2-aminohexadecanoic acid)-b-poly(β-benzyl-L-aspartic acid) (PEG-b-PAPA-b-PBLA) three Synthesis of Block Copolymers

[0038] The PEG-b-PAPA-b-PBLA triblock copolymer was prepared in the form of PEG-NH in DMF solution under nitrogen 2 2-aminohexadecanoic acid-N-carboxylate anhydride monomer (APA-NCA) and β-benzyl-L-aspartic acid-N-carboxylate anhydride monomer (BLA- NCA) prepared by ring-opening polymerization. The specific synthesis steps are as follows: under a nitrogen atmosphere, a DMF solution of 10 mL of APA-NCA (0.52 g, 1.76 mmol) was rapidly added to PEG-NH 2 DMF (2 mL) solution, after reacting at 35° C. for 72 hours, the second monomer BLA-NCA was added, and then the reaction was continued for 72 hours. After the reaction, the reaction solution was precipitated in 20 times excess glacial ether for several times, and finally vacuum-dried to obtain a white solid product. Yield: 83%.

[0039] The NMR spectrum of PEG-b-PAPA-...

Embodiment 2

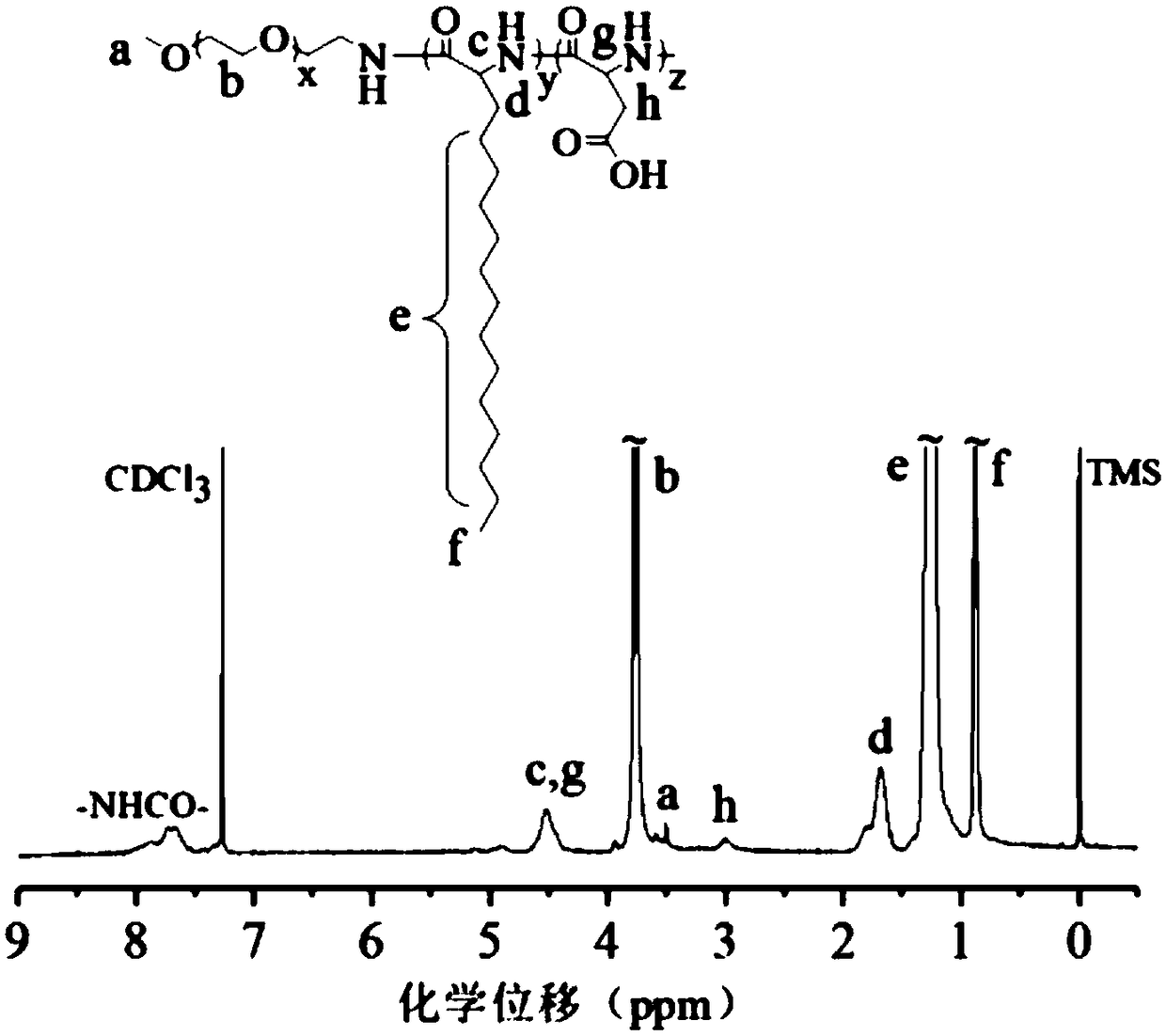

[0040] Embodiment 2: Synthesis of PEG-b-PAPA-b-PAsp copolymer

[0041]PEG-b-PAPA-b-PAsp triblock copolymer was obtained by deprotecting PEG-b-PAPA-b-PBLA in HBr. The specific steps are as follows: HBr (33wt.% HOAc, 0.3mL, 1.66mmol) was added to a solution of PEG-b-PAPA-b-PBLA (0.3g, 0.015mmol) in trifluoroacetic acid (3mL) and reacted at 0°C 2 hours. After the reaction was finished, precipitation was repeated several times with excess glacial ether, and finally vacuum-dried to obtain a white solid product. Yield: 80%.

[0042] The NMR spectrum of PEG-b-PAPA-b-PAsp is attached figure 2 , 1 H NMR (600MHz, CDCl 3 / CF 3 COOH(9 / 1,v / v), figure 2 ,δ):4.50(1H,-COCHNH-),3.72(4H,-OCH 2 CH 2 O-),3.47(3H,-OCH 3 ),2.99(2H,-COCH 2 -),1.82(2H,-CH(NH)CH 2 CH 2 -),1.24(24H,-CH 2 (CH 2 ) 12 CH 3 ),0.85(3H,-CH 2 CH 3 ).

[0043] Table 1. Characterization of PEG-b-PAPA-b-PBLA triblock copolymers

[0044]

[0045] a Depend on 1 Calculated by H NMR. b Measured by GPC (m...

Embodiment 3

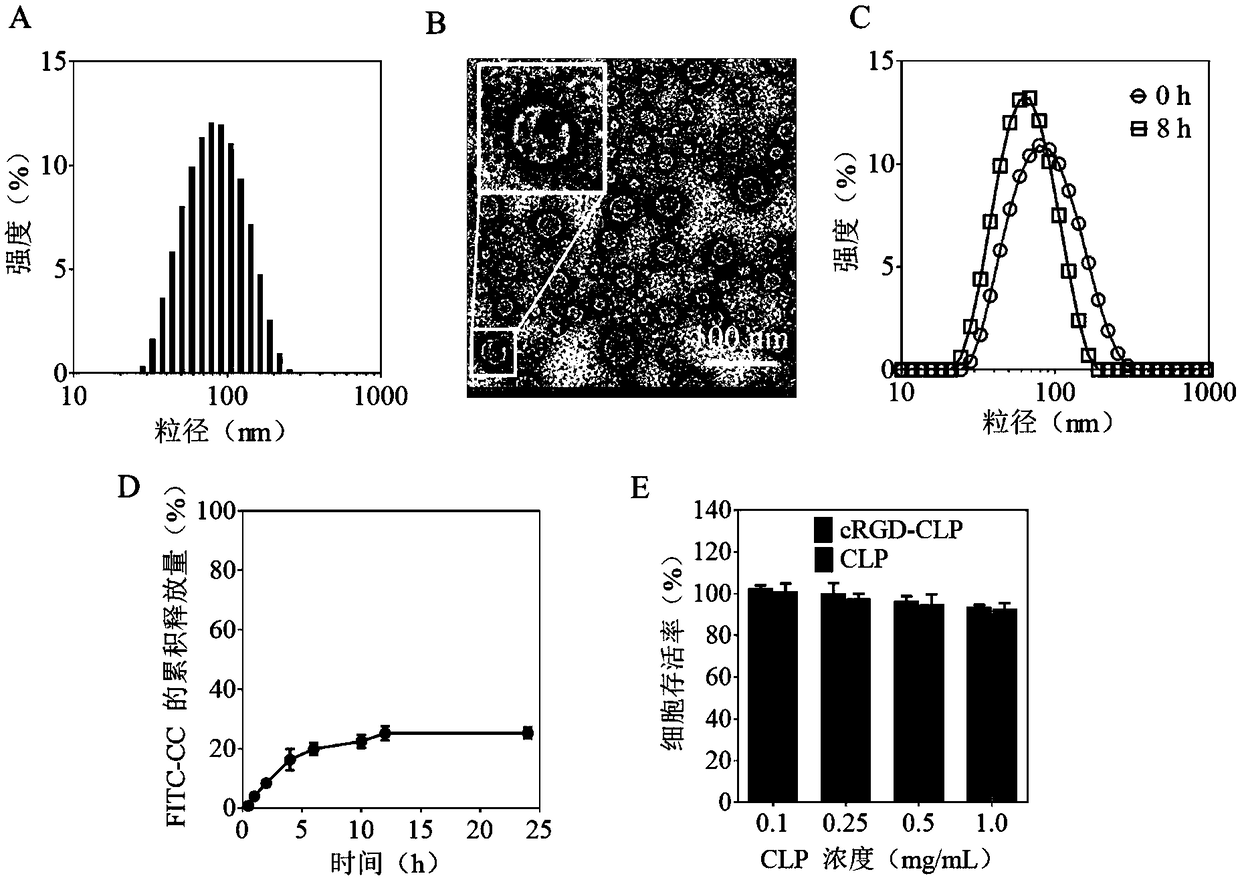

[0046] Example 3: Preparation of Polylipopeptide Vesicles with Asymmetric Membrane Structure and Determination of its Critical Aggregation Concentration (CAC)

[0047] cRGD-modified polylipopeptide vesicles (cRGD-CLP) were prepared by solvent displacement method. The brief steps are as follows: 0.2 mL of 2 mg / mL containing 20 mol.% cRGD-PEG-b-PAPA (M n =6.0-11.3kg / mol) and 80mol.% mPEG-b-PAPA-b-PAsp (M n =5.0-10.1-1.4kg / mol) was added dropwise to 0.8mL of PB buffer medium (10mM, pH 7.4), and then dialyzed in PB for 8 hours, changing the dialysis medium every 2 hours. The critical aggregation concentration (CAC) of polylipopeptide vesicles was measured by fluorescence method using pyrene as fluorescent probe. The concentrations of cRGD-CLP and CLP ranged from 1.2 × 10 -5 to 0.1 mg / mL and the concentration of pyrene in each sample was 0.6 μM. Fluorescence intensity at 372 nm and 383 nm was recorded by a fluorescence spectrophotometer under excitation at 330 nm. The inflecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com