Preparation of malathion hydrolase by immobilization method of cross-linked enzyme aggregates

A malathion and hydrolase technology, applied in the direction of immobilized enzymes, hydrolase, chemical instruments and methods, can solve the problems of reducing the mass transfer efficiency between enzymes and substrates, changing the conformation of enzymes, and reducing enzyme activity, etc., to achieve Good degradation effect, good activity and stability, and high immobilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

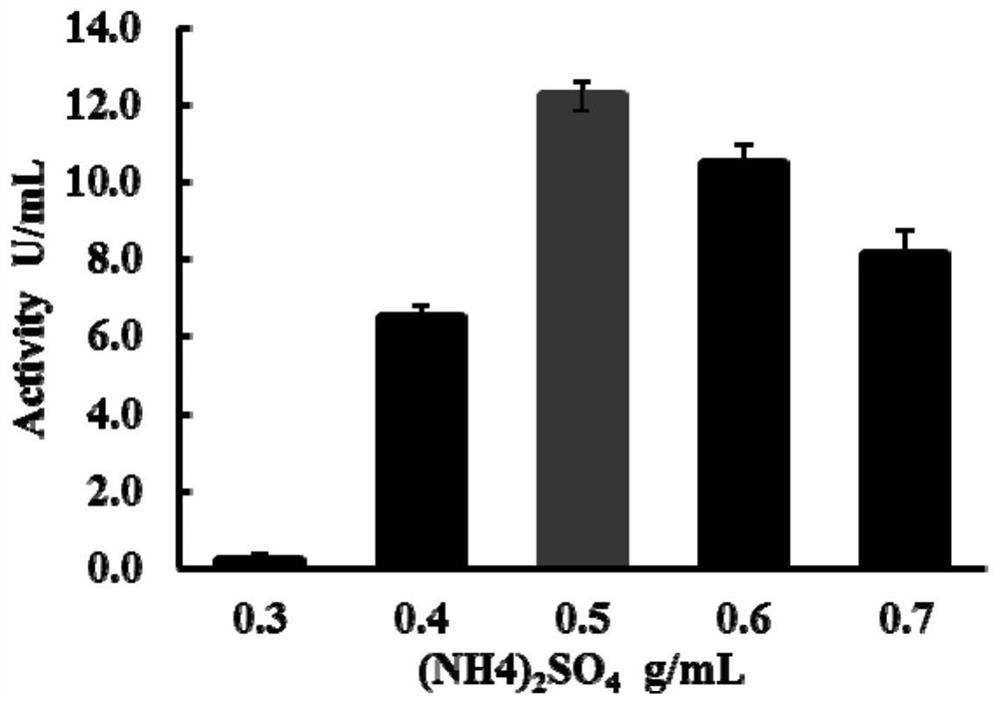

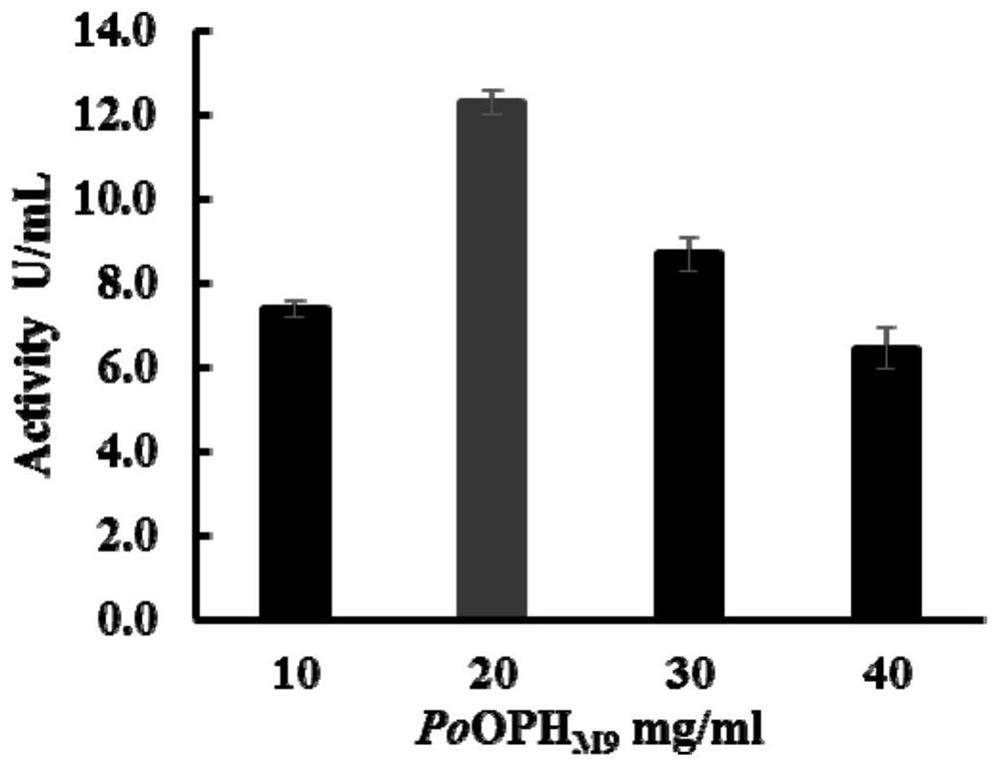

[0033] Organophosphate hydrolase (that is, malathion hydrolase Pseudomonas oleovorans DSM50188) was dissolved in 1 mL of 50 mM phosphate buffer solution (pH 7.0) buffer, the concentration of malathion hydrolase was 20 mg / ml, and ammonium sulfate was first added for aggregation Then add polyether Pluronic F127, the mass ratio of polyether Pluronic F127 to malathion hydrolase 1:4, stirred at 4°C for 30 min; finally added glutaraldehyde, the concentration of glutaraldehyde was 90 mM, and cross-linked at 4°C for 3 h. After the reaction, the reaction solution was collected and centrifuged at 12000 rpm for 3 minutes to separate the immobilized enzyme.

[0035] The immobilized enzyme was placed in a constant temperature shaking reactor at 50°C for 7 hours. Add a certain amount of immobilized enzyme to 1ml of 50mM Tris-HCL (pH 9.0, containing 2mM Ellman reagent) buffer solution containing 0.5mM malathion at a final concentration of 0.5mM malathion for...

Embodiment 2

[0043] A method for immobilizing malathion hydrolase by cross-linking enzyme aggregates comprises the following steps:

[0044] (1) Add a certain amount of ammonium sulfate to the malathion hydrolase solution and stir evenly, and obtain aggregates of malathion hydrolase by salting out;

[0045] (2) adding a certain concentration of polyether to the aggregate to obtain a combination of aggregate and polyether;

[0046] (3) Finally, a certain concentration of glutaraldehyde is added to carry out the cross-linking reaction, and the insoluble particles obtained by centrifugation or filtration after the end are the immobilized enzymes.

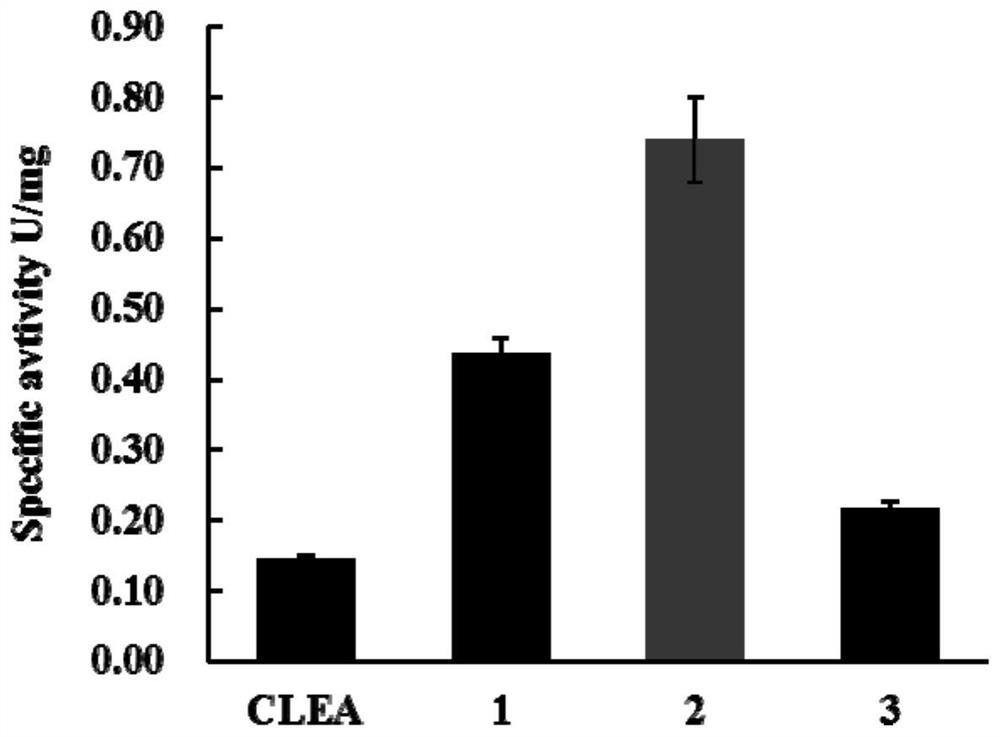

[0047] figure 1 It is a comparison chart of the effect of the traditional immobilization method and the new cross-linked aggregate immobilization method, which shows that the specific activity of all cross-linking methods after adding polyether Pluronic F127 is higher than that of conventional CLEA, and the best addition method is: PoOPHM9 Precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com